Method and device for producing organic acid or alcohol by fermenting synthetic gas

A technology for organic acids and syngas, which can be used in fermentation, biofuels, etc., to solve the problems of reduced conversion rate of gas substrates and increased energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

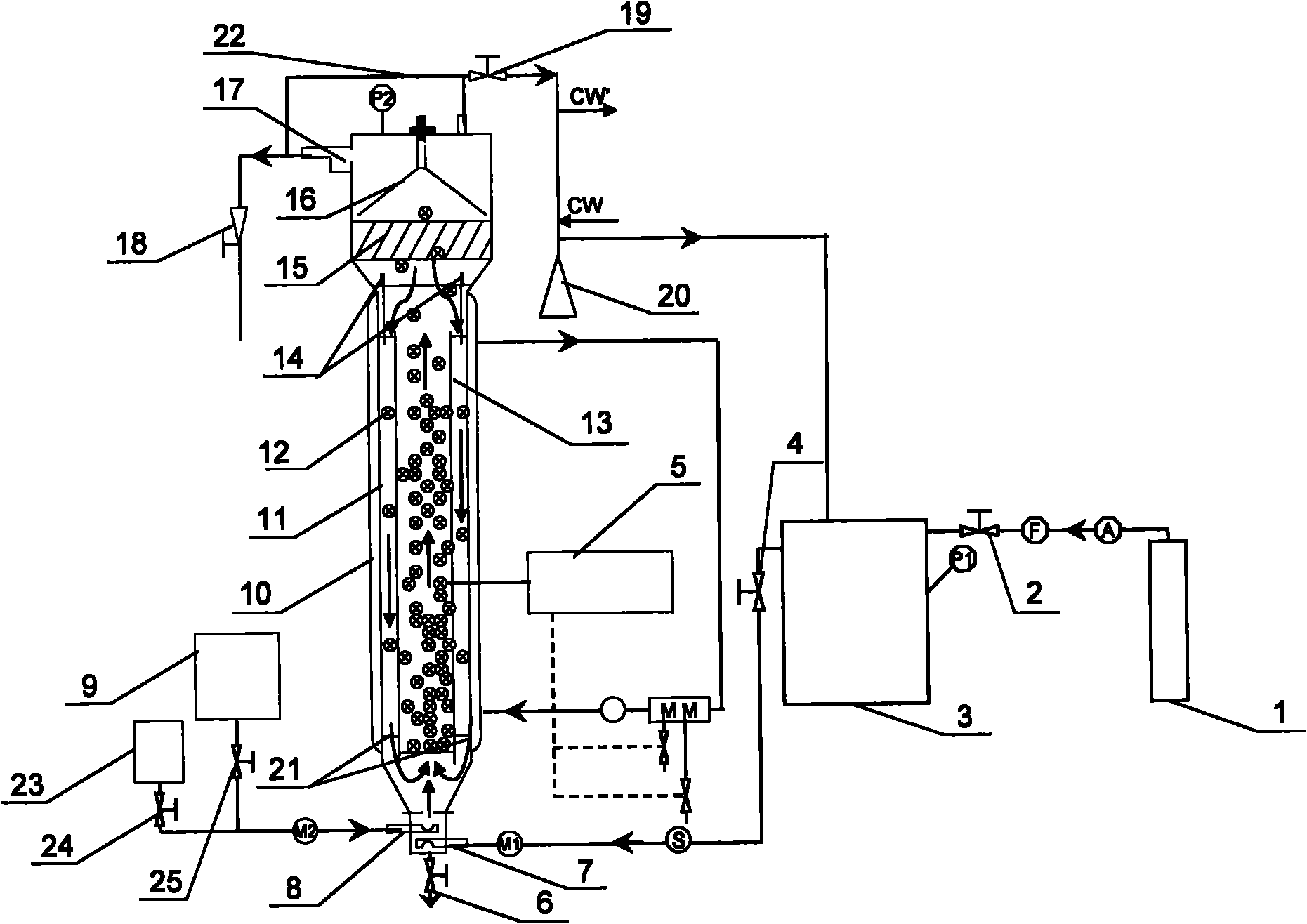

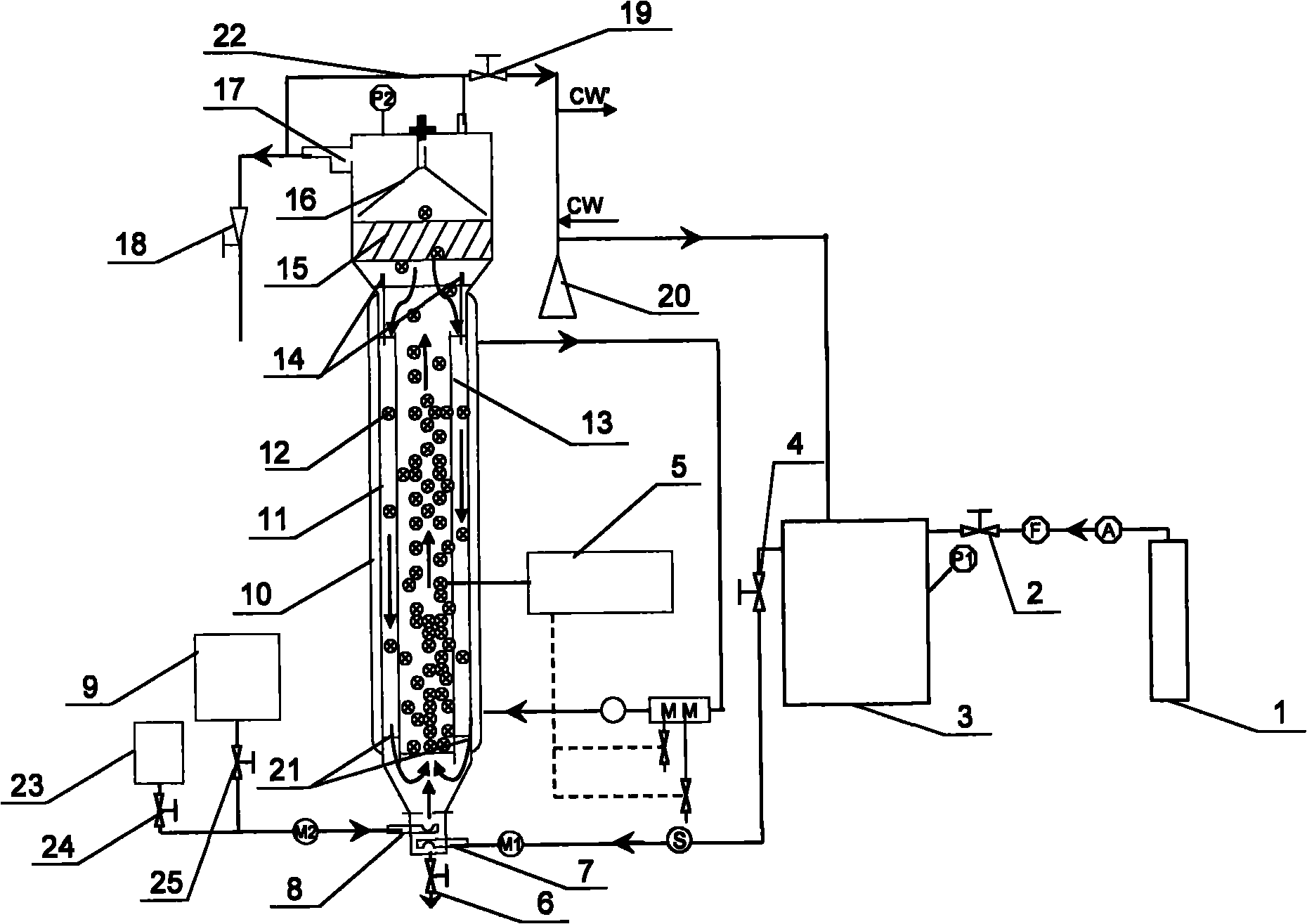

[0033] see figure 1 As shown, a method for producing organic acid or alcohol by fermenting synthesis gas in a biological fluidized bed, the reactor used is a three-phase circulating anaerobic fluidized bed reactor, which consists of a fluidized bed main body, an external gas circulation supply system, and a cultivation Base supply and product recovery system and temperature control system are composed of four parts.

[0034] The bottom of the main body of the fluidized bed is provided with a stop valve 6, a gas distributor 7 and a liquid distributor 8 respectively from bottom to top. The opening of the gas distributor is downward, and the opening of the liquid distributor is upward, which facilitates the uniform distribution of gas and liquid and prevents the carrier conditions such as accumulation or short circuit. The reaction zone in the middle is a three-layer concentric cylinder, which respectively includes a jacket outer wall 10, an outer cylinder 11 and an inner cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com