Low odor compositions and low odor coating compositions

A composition and water-based composition technology, applied in the direction of polyester coatings, coatings, etc., can solve problems such as coating or paint properties, enzyme degradation, etc. that have not been discussed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

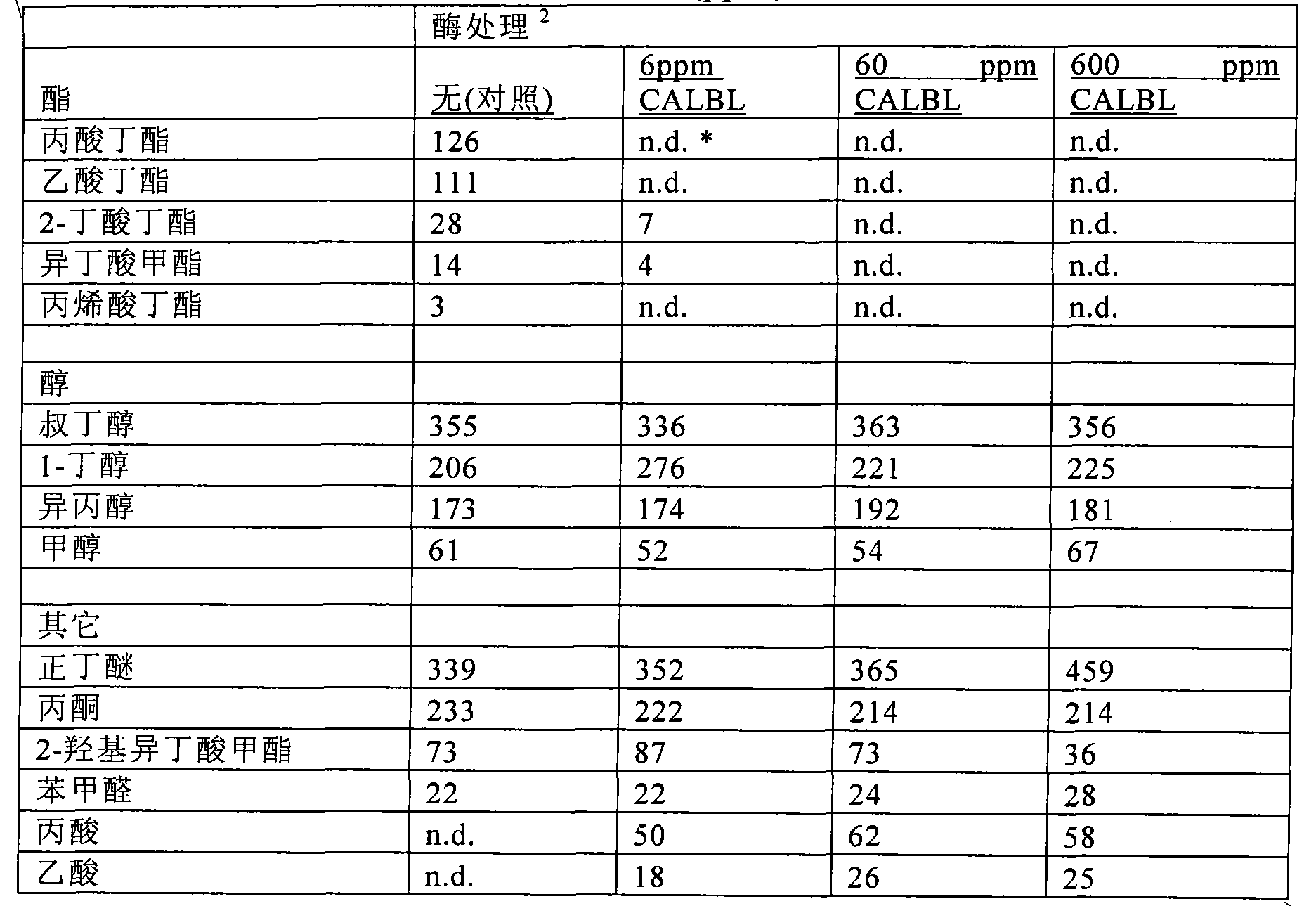

[0148] Example 1 Determination of headspace VOC content based on ASTM D3960-05

[0149] Determination of headspace in aqueous compositions based on ASTM 3960: Standard Practice for Determining Volatile Organic Compound (VOC) Content of Paints and Related Coatings VOC content. This method uses static headspace sampling / GC-MS to determine the concentration of headspace compounds above waterborne emulsion polymers or waterborne paints at 33°C.

[0150] Preparation of standards: Calibration standards are prepared in a suitable solvent (eg THF, tetrahydrofuran) containing a minimum of three concentrations of each compound to be calibrated. Standard concentrations should be prepared by serial dilution and calculated in ppm on a weight / weight basis. The concentration of each compound in the lower and higher concentration standards should produce a detector response signal, and the response of the compound is used for sample analysis. 20 mg of each standard was weighed into 22 ml...

Embodiment 2

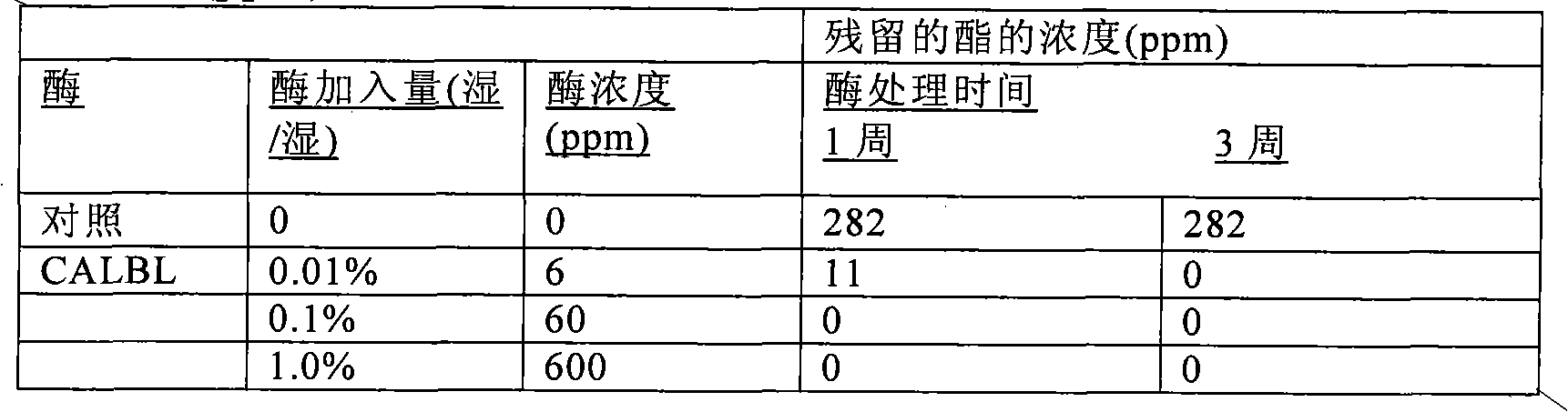

[0152] Example 2 Determination of enzymatic hydrolysis activity

[0153] The procedure used to determine the enzyme activity of emulsion polymer latexes or latex paints is similar. For emulsion polymer latex, a 100 gram sample of emulsion polymer latex binder was treated with different enzymes at concentrations ranging from 2.5 to 1000 ppm (weight of enzyme solids based on wet latex weight). After equilibrating for 1 day, samples were further treated with approximately 600 ppm of ethyl acrylate (EA) and incubated in sealed jars at room temperature at pH = 8.5 for 48 hours. 5 g samples were taken at 15 min, 75 min, 135 min, 1440 min and 2880 min intervals, diluted with 5 g of deionized water, quenched with 100 ppm of 48% phosphoric acid to a pH of approximately 1.6, and mixed well . The catalytic activity of the free enzyme was then determined by calculating the change in headspace EA in the inhibited latex samples using GC-MS or GC / FID (by the method of Example 1) at time ...

Embodiment 3

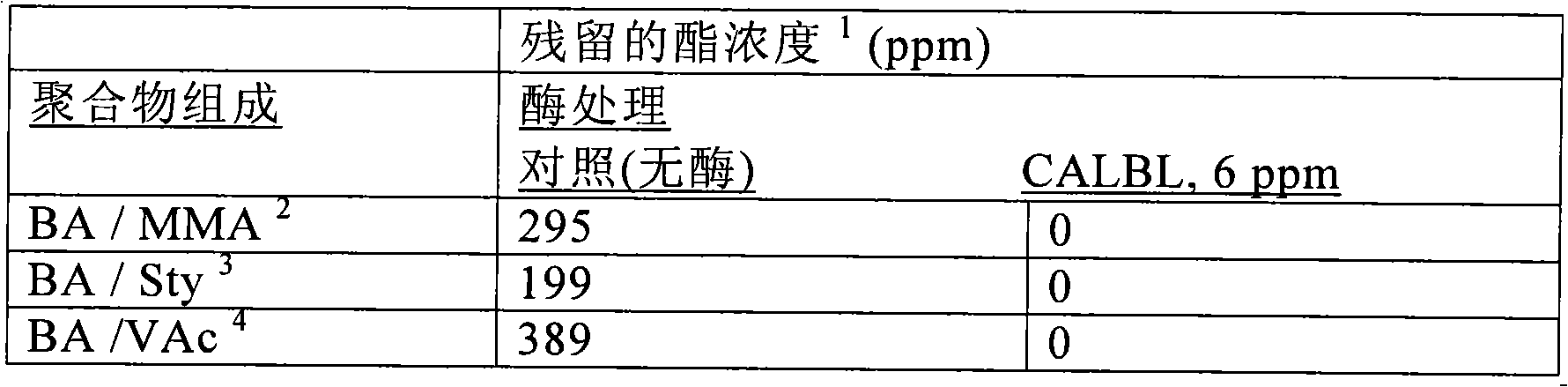

[0154] Example 3: Synthesis of Emulsion Polymer Latex, Polymer A

[0155] A monomer emulsion was formed from the following components: 1397 grams of ethyl acrylate, 386 grams of methyl methacrylate (and <2 wt. Ionized water and 51.8 grams of anionic surfactant (30% active), emulsified under agitation. Into a 4 liter multi-neck flask equipped with mechanical stirring was added 9 grams of anionic surfactant (30% active) and 547 grams of deionized water. The contents of the flask were heated to 75°C under a nitrogen atmosphere. 67 grams of monomer emulsion were added to the stirred flask contents, followed by 0.02 grams of ferrous sulfate heptahydrate dissolved in 23.5 grams of deionized water and 0.02 grams of EDTA tetrasodium salt and sodium carbonate (based on the total amount of monomers) count less than 0.5%). Polymerization was initiated by adding 1.2 grams of sodium persulfate dissolved in 36 grams of deionized water and 0.6 grams of sodium bisulfite dissolved in 5 gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com