Preparation of vacuum freeze-drying shrimp meat

A shrimp and freeze-drying technology, applied in the field of food processing, can solve the problems of short shelf life, taste change, high cost, etc., and achieve the effect of long shelf life, good rehydration, and convenient consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0024] [Implementation case 1] Determination of the eutectic point of shrimp

[0025] The state in which the solute and water are both frozen is a eutectic, and the freezing temperature is the eutectic point, which can be determined by the resistance method. In the process of gradually heating up the shrimp from the frozen state, the resistance in the shrimp will gradually decrease, and when the eutectic point is reached, the resistance will change suddenly. Freeze 200g of shrimp in a -80°C refrigerator for 2 to 3 hours, take out the frozen shrimp, make it warm up gradually, and observe the change of its resistance value. Through the above experiments, it is found that when the temperature of the shrimp increases to -20~-25°C, the resistance value of the shrimp changes suddenly, so it is determined that the eutectic point of the shrimp is at -20~-25°C.

Embodiment example 2

[0026] [Implementation Case 2] Preparation of Freeze-dried Shrimp

[0027] Weigh 100g of fresh shrimp, wash it twice with clean water, drain, and pre-freeze the shrimp to about -10°C by cooling on a shelf, and then vacuumize to accelerate the freezing speed until the temperature of the shrimp drops to -30°C, entering the sublimation drying stage. The temperature of the sublimation drying plate rises gradually until the temperature of the shrimp is near the eutectic point and maintains this temperature, and the vacuum degree is kept at 30-35pa until the temperature of the shrimp rises suddenly, the sublimation drying stage is over, and it enters the analysis drying stage and continues to rise. High shelf temperature, but controlled below 35°C, maintain a vacuum of 20-30pa until the end of the analysis, that is, freeze-dried shrimps are obtained, weighed to obtain 18.3g, and the calculated dry ratio (fresh weight / dry weight) is 5.78.

Embodiment example 3

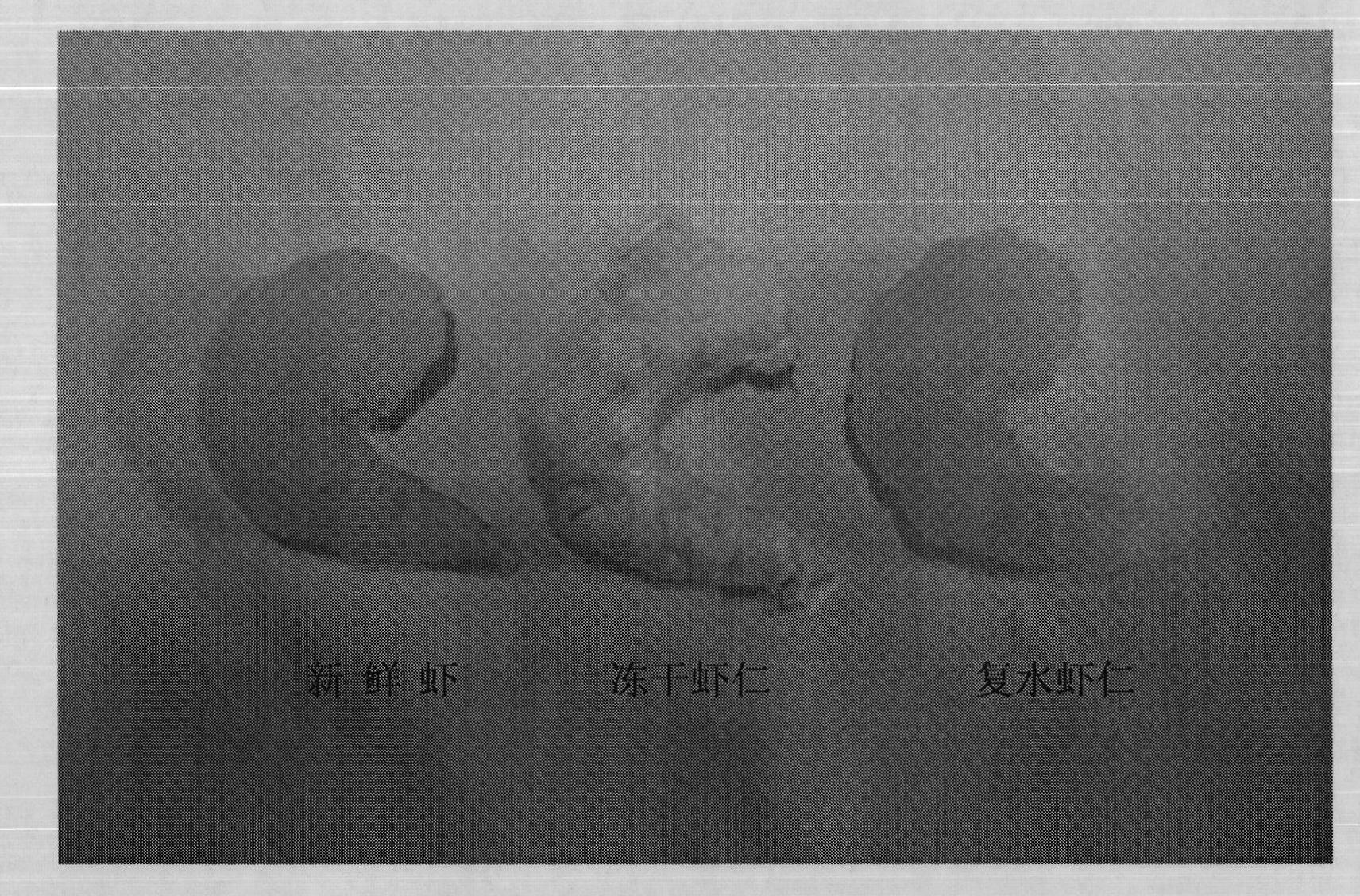

[0028] [Implementation Case 3] Determination of Rehydration Ratio of Freeze-dried Shrimp

[0029] Take 10 freeze-dried shrimps and weigh them (G dry). Put 10 shrimps into a beaker filled with 200ml of water, bathe in 18°C water, and stir gently with a glass rod. After the predetermined time, take out the shrimps, drain them, and weigh them. Repeat (G complex), calculate the rehydration ratio (R complex), R complex = G complex / G dry, draw freeze-dried shrimp rehydration 1, 2, 3 hours, the rehydration ratio is 3.68, 4.01, 4.2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com