Etching device of micro-nano ferroelectric domain structure based on atomic force microscope acoustic microscopy system

A technology of atomic force microscope and etching device, which is applied in the direction of microstructure device, manufacturing microstructure device, nanostructure manufacturing, etc., to achieve high-resolution imaging and evaluation, improve precision, and increase processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

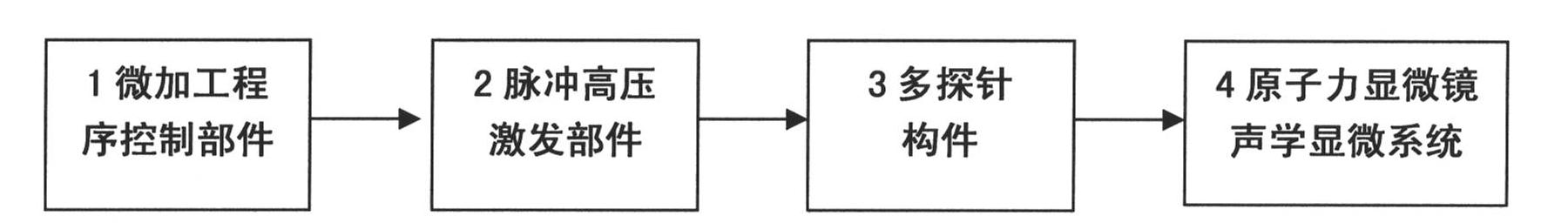

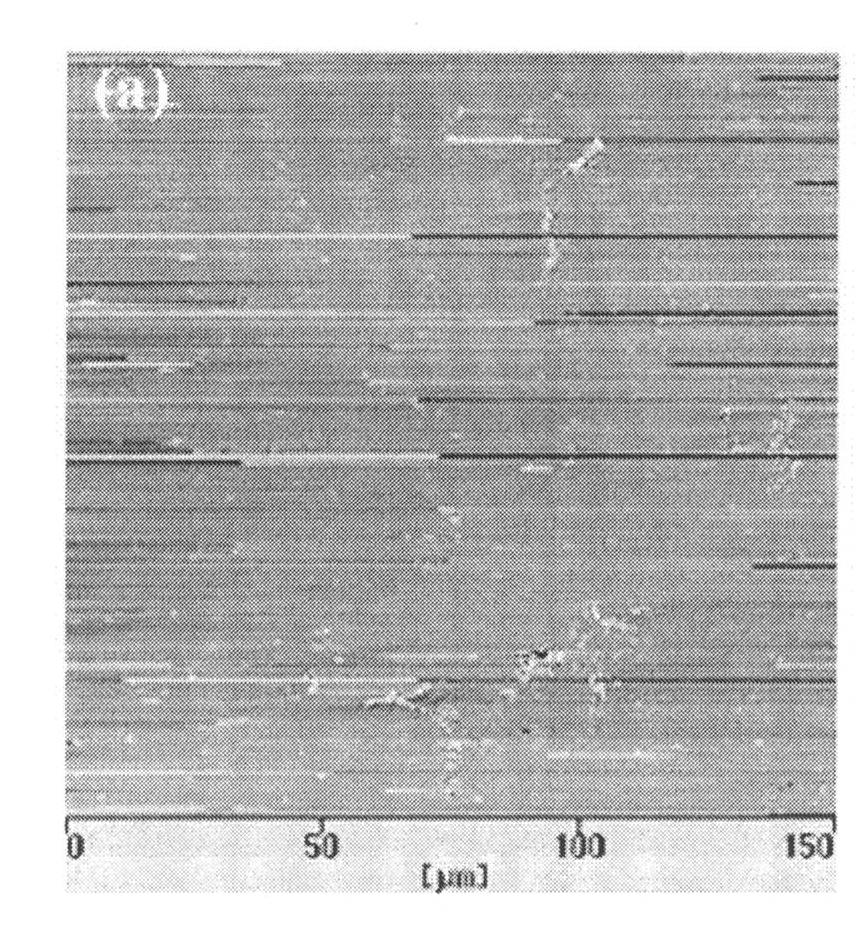

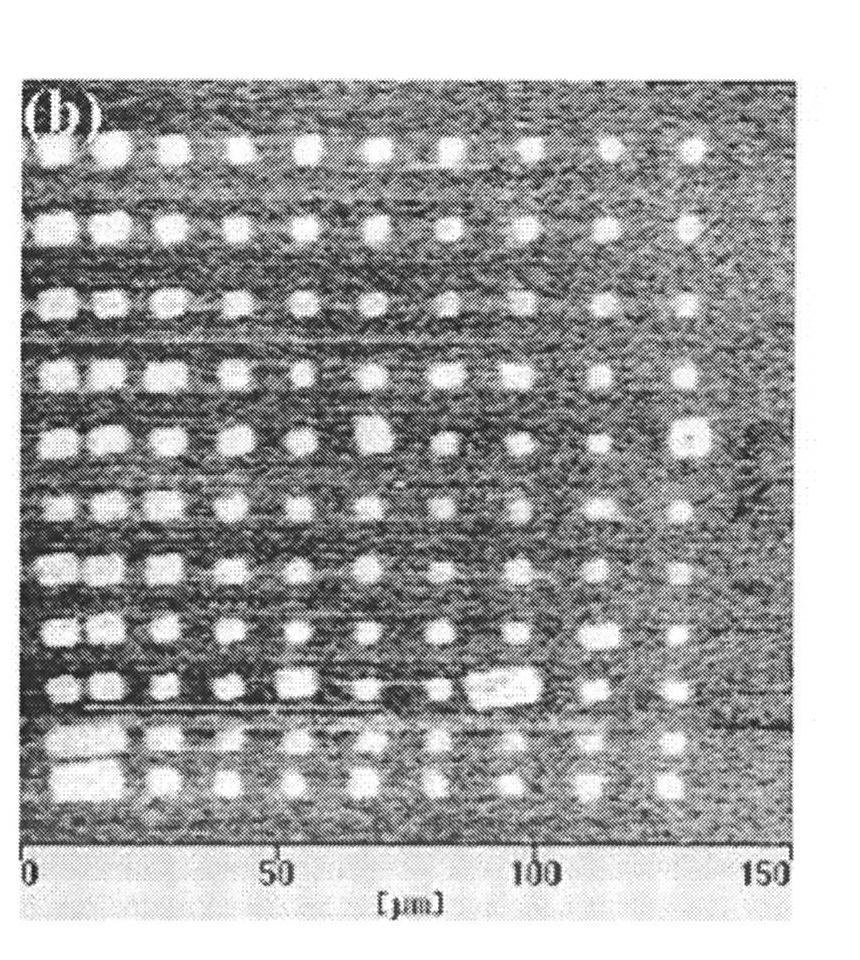

[0033]Embodiment 1: The microstructure processing of BMF ferroelectric single crystal is carried out by applying the nano-acoustic etching system constructed in the present invention, and Fig. 2 shows the test results. Figure 2(a) is the AFM image of the surface topography of the BMF single crystal sample, and Figure 2(b) is the acoustic imaging of the micromachined ferroelectric domain structure obtained in situ in the corresponding region of the sample. Obviously, Figure 2(a) is very different from Figure 2(b). The topography image 2(a) only shows the information of polishing scratches on the sample surface, while the acoustic image 2(b) clearly shows the dot-like ferroelectric domain array structure when the micromachining voltage is 190V / 10μs. Figure 2(c) is the acoustic image result of the column-like ferroelectric domain array microfabricated in another area of the sample, and Figure 2(d) is the acoustic signal of the line A-B in Figure 2(c), showing that the column-li...

Embodiment 2

[0034] Embodiment 2: Application of the nanoacoustic etching system formed by the present invention to another BaTiO 3 Ferroelectric single crystal microstructure processing, Figure 3 shows the test results. Similar to Example 1 above, Fig. 3(a) is the AFM image of the surface topography of the sample, and Fig. 3(b) is the acoustic imaging of the micromachined ferroelectric domain structure obtained in situ in the corresponding region of the sample. Acoustic image Figure 3(b) clearly shows the ferroelectric domain array structure when the micromachining voltage is 230V / 5μs. The mechanism of the assembly of metal nanoparticles is also of great reference value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com