Radiation cross-linked polyethylene thermal expansion pipe and manufacturing method

A radiation cross-linking, polyethylene technology, applied in the field of plastic pipes, can solve the problems of having to operate on the construction site, short-term memory effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Radiation cross-linked polyethylene thermal expansion tube, its composition includes: linear polyethylene LLDPE, high-density polyethylene HDPE, low-density polyethylene LDPE, copolymer EVA of vinyl acetate and ethylene, tetrakis [β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionate] pentaerythritol ester and black masterbatch, the parts by weight of the linear polyethylene LLDPE is 100, the parts by weight of the high-density polyethylene HDPE is 30, the parts by weight of the described The parts by weight of the low-density polyethylene LDPE is 20, the parts by weight of the copolymer EVA of vinyl acetate and ethylene is 10, and the parts by weight of the tetrakis[β-(3,5-di-tert-butyl-4-hydroxy The parts by weight of phenyl) propionate] pentaerythritol ester is 0.8, and the parts by weight of the described black masterbatch is 0.6, and the described black masterbatch is a kind of saturated carbon black used in plastic processing to adjust the processed The granular r...

Embodiment 2

[0022] The manufacturing method of the radiation-crosslinked polyethylene heat-expandable tube described in embodiment 1:

[0023] Step 1: Take various raw materials of the radiation cross-linked polyethylene thermal expansion pipe according to the above ratio, and extrude the pipe.

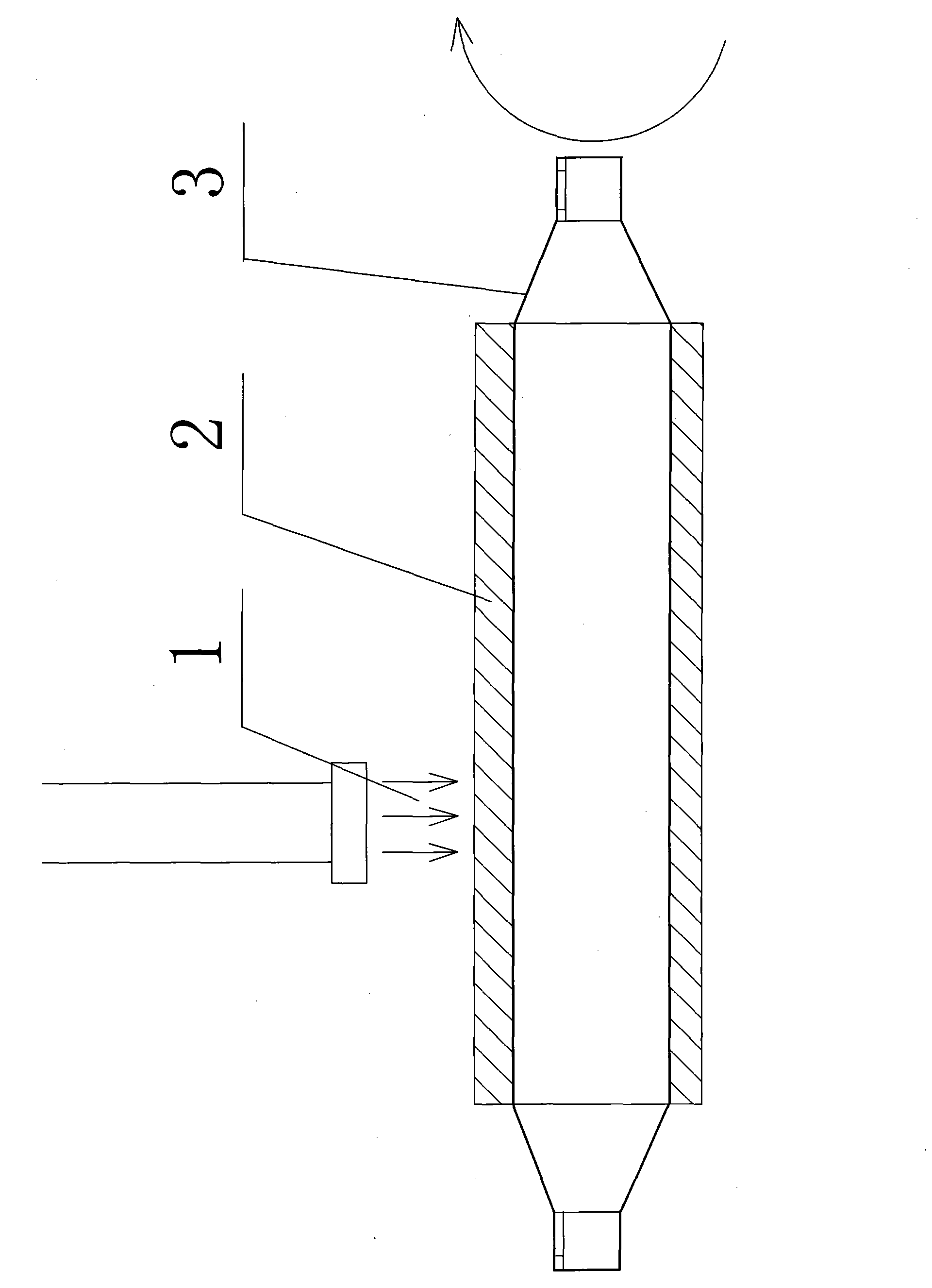

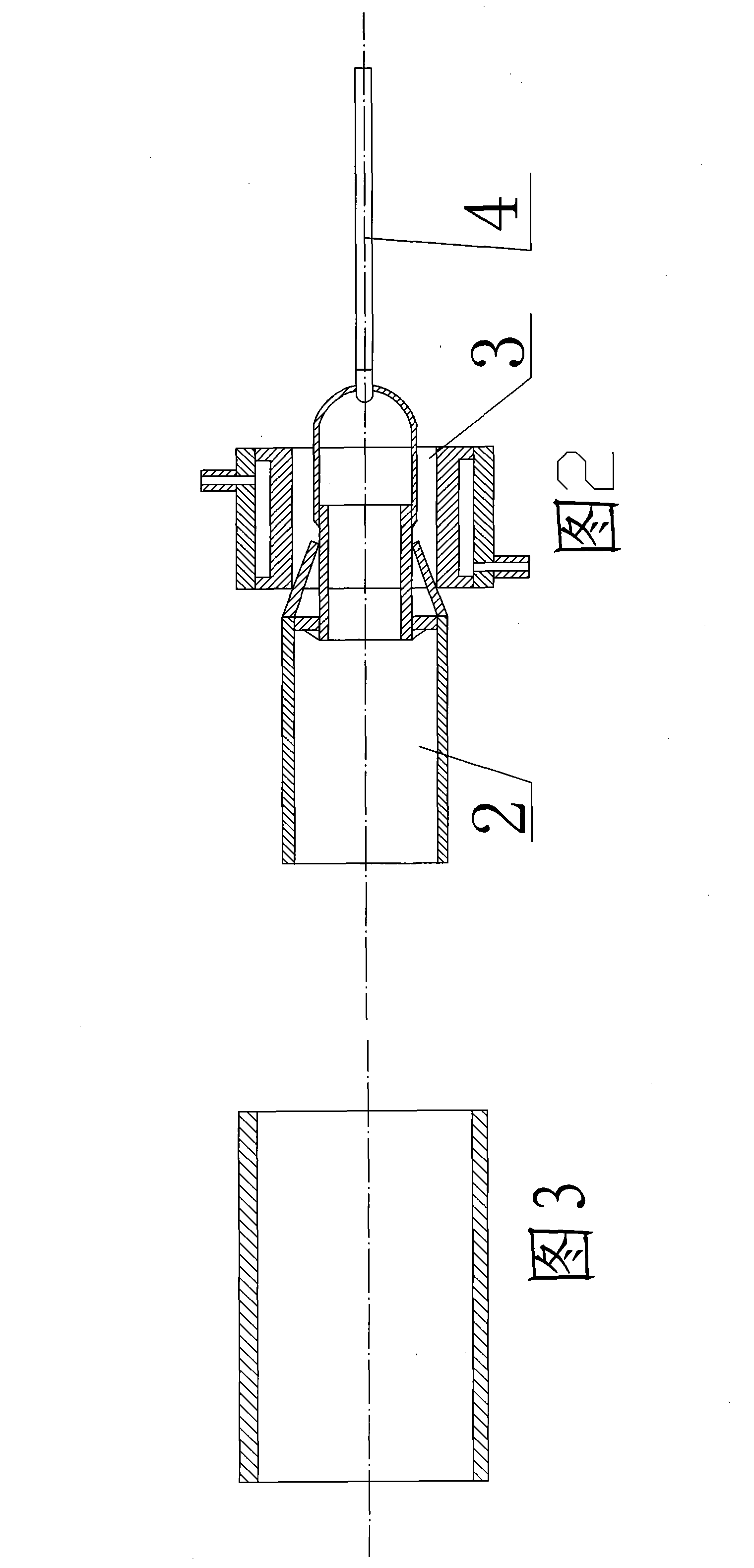

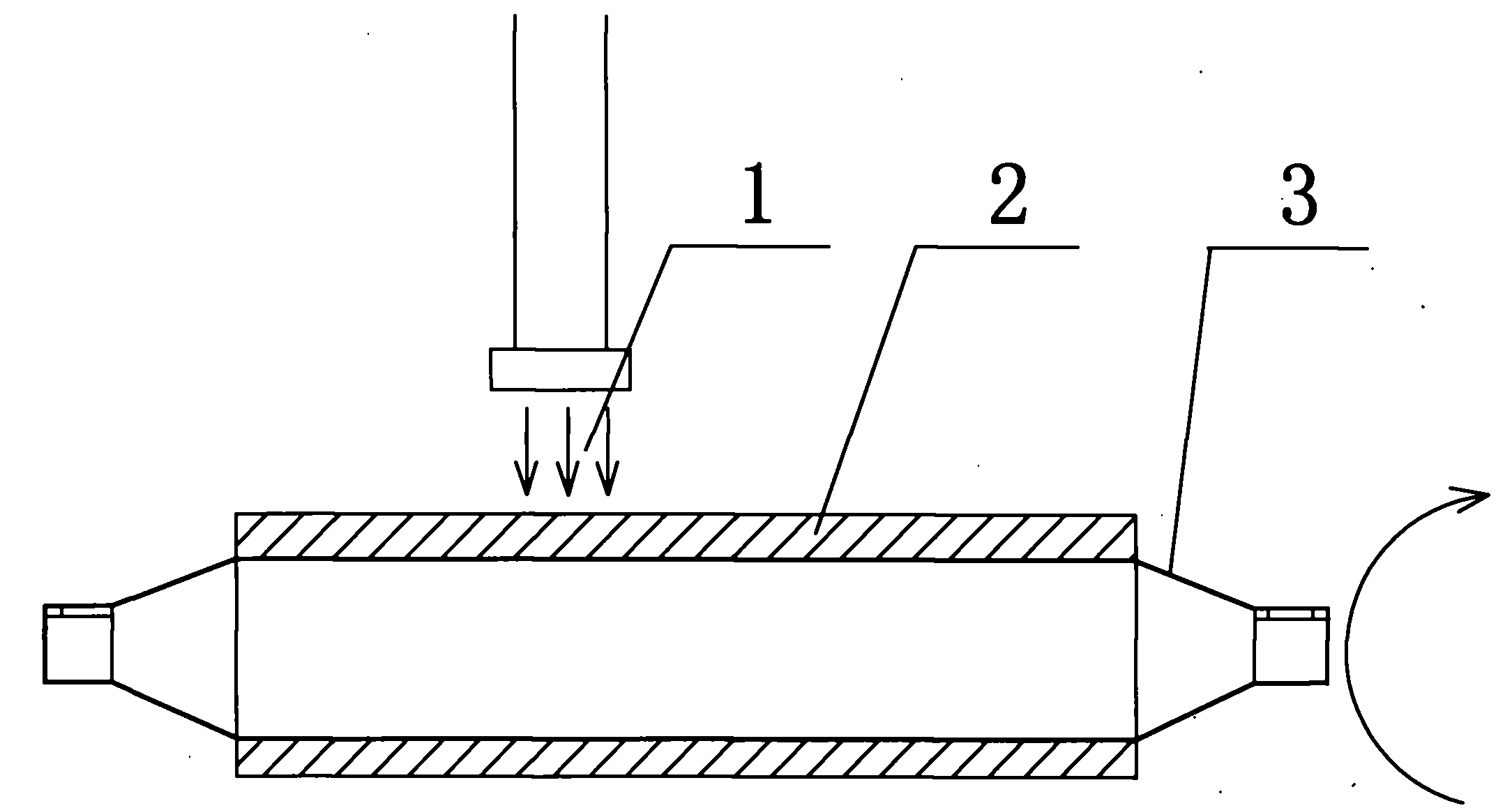

[0024] Step 2: Saw the pipe extruded in the first step into a pipe section 2, put the sawed pipe section 2 on the squirrel cage 3, rotate and translate, the moving direction is perpendicular to the scanning direction, and the moving speed of the pipe is 1 m / min , cross-linked plastic tubing was obtained after scanning the box several times through an electron accelerator 1 . The irradiation dose is 90-110 kJ / kg, and the degree of cross-linking is 50%-60%.

[0025] Step 3: Clamp the pipe cross-linked in the second step on the prefabricated fixture, put it in the temperature control box for preheating, the preheating temperature is 135°C±5°C; pull the preheated pipe through a fixed Diameter mold,...

Embodiment 3

[0027] The radiation-crosslinked polyethylene thermal expansion pipe described in embodiment 1 or 2, the plastic pipe made by the above method can be made of radiation-crosslinkable polyethylene PE or polyethylene PE and ethylene vinyl acetate copolymer EVA The polymer produced by the blend; the wall thickness of the plastic pipe is: 2mm-5mm, the outer diameter of the pipe is 40mm-300mm, the gel rate of the pipe is 50%-60%, and the radial expansion rate after heating is 5%- 15%, axial shrinkage 4%-13%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com