Cosmetic composition for anti-aging of the skin comprising phaseolus radiatus seed extracts by fermentation and enzyme treatment

A cosmetic composition and mung bean extract technology are applied in the directions of skin care preparations, medical preparations containing active ingredients, cosmetics, etc., and can solve problems such as external skin irritation and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

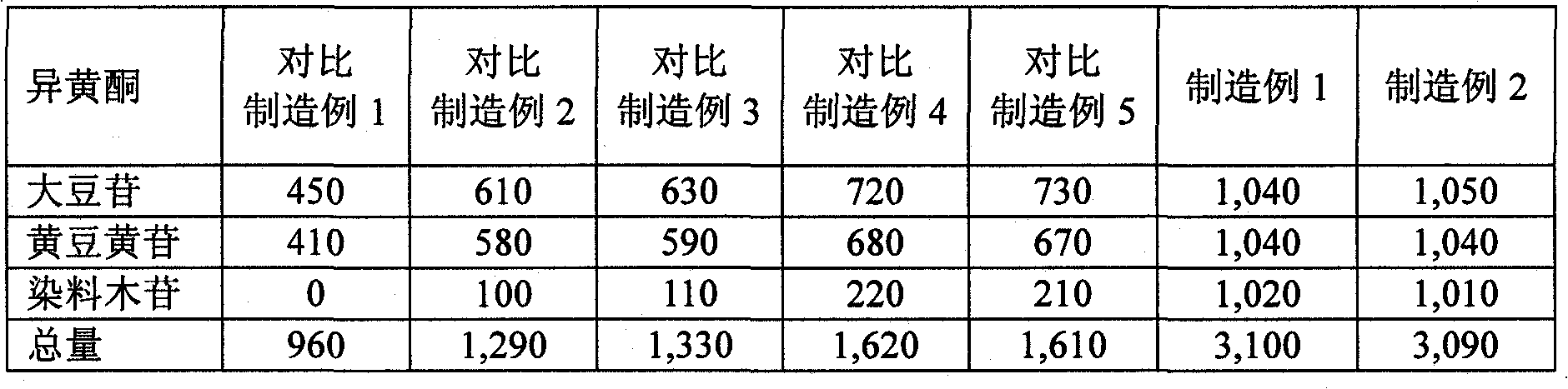

preparation example Construction

[0027] In the preparation method of the fermentation-enzyme-treated mung bean extract, the mung bean is ground into a powder of 100-500 mesh or finer in step (a), but it is not always limited thereto.

[0028] In step (b), the fermentation is carried out as follows: Mung bean powder and purified water are mixed at a ratio of 1:10, sterilized at 121°C, and then used Lactobacillus sp or Saccharomyces sp. Inoculate and then cultivate.

[0029] The preferred amount of yeast or lactic acid bacteria used for fermentation is 1×10 per 1L of total culture solution. 4 To 1×10 5 Cells. According to each strain, conventional culture conditions (aerobic conditions or facultative anaerobic conditions) can be used. In order to activate the culture of fermenting organisms, additional carbon sources and / or pH regulators can be added. The preferred culture conditions are as follows: 30-37°C; pH 5-7; aerobic or facultative anaerobic conditions; culture for 1-15 days, preferably 1-7 days, more prefe...

manufacture example 1

[0059] Production Example 1: Preparation of mung bean extract by yeast fermentation-enzyme treatment

[0060] The mung beans were washed with purified water and dried, then milled, and filtered with a 300 mesh filter cloth to produce fine powder. Mix mung bean powder and purified water at a ratio of 1:10, and then sterilize at 121°C. The resulting mixture is inoculated with yeast. The yeast used here is Saccharomyces cerevisiae with a concentration of 50,000 cfu / L. In a 5L fermentor, culture was performed at 30°C and pH 5.5 for 3 days. Once the culture is completed, the resulting culture broth is centrifuged to remove the yeast, followed by preliminary filtration with a 0.45 μm filter membrane. The resultant filtrate was treated with protease (pepsin, Sigma, USA) for 2 hours, and then subjected to secondary filtration with a 0.25 μm filter membrane. The filtrate obtained is then concentrated and diluted with a suitable solvent. The prepared fermentation-enzyme extract was na...

manufacture example 2

[0061] Production Example 2: Preparation of lactic acid bacteria fermentation-enzyme-treated mung bean extract

[0062] The mung beans were washed with purified water and dried, then milled, and filtered with a 300 mesh filter cloth to produce fine powder. Mung bean powder and purified water were mixed at a ratio of 1:10 and sterilized at 121°C. The resulting mixture was inoculated with lactic acid bacteria. The lactic acid bacteria used here are of the genus Lactobacillus with a concentration of 50,000 cfu / L. In a 5L fermentor, culture was performed at 30°C and pH 5.5 for 3 days. Once the culture is completed, the resulting culture solution is centrifuged to remove the bacteria, and then preliminarily filtered with a 0.45 μm filter membrane. The obtained filtrate was treated with protease (pepsin, Sigma, USA) for 2 hours, and then filtered twice with a 0.25 μm filter membrane. The filtrate obtained is concentrated and diluted with a suitable solvent. The prepared fermentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com