Internal cooling of internal combustion engine

A technology for internal combustion engines and cooling methods, applied in mechanical equipment, engine components, machines/engines, etc., to solve problems such as power rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

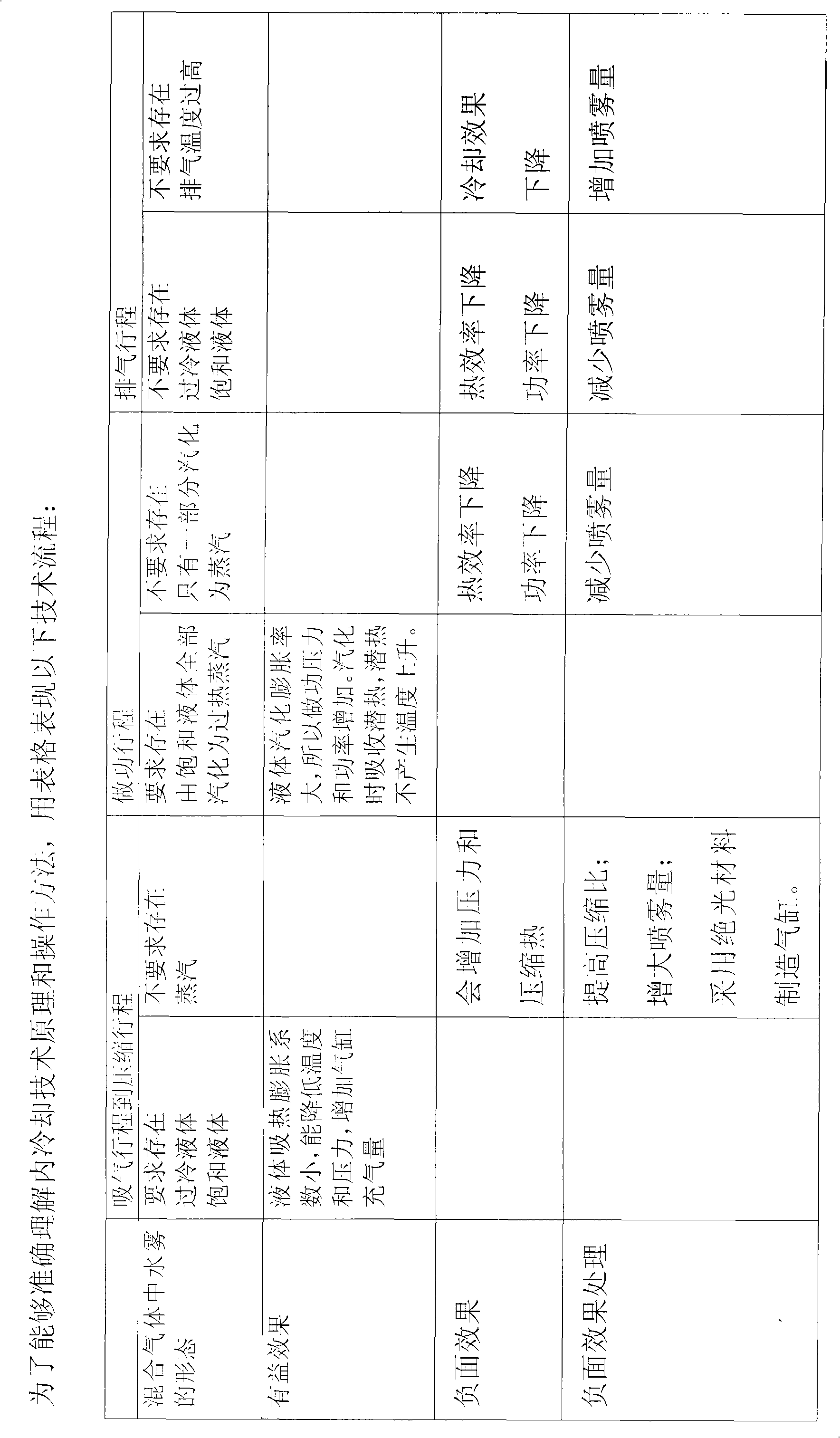

Image

Examples

Embodiment Construction

[0005] Install a pressure spray device on the intake manifold of the adiabatic internal combustion engine and the adiabatic internal combustion engine; install a temperature sensing device near the exhaust valve; install an exhaust temperature control module. The temperature sensing device inputs the exhaust gas temperature signal to the control module, and the control module automatically controls the spray volume of the spray device after processing the signal. The change of spray volume, adjust the exhaust temperature within the set temperature range. The substance to be sprayed is water or a water solvent.

[0006] When the internal cooling of the adiabatic internal combustion engine and the adiabatic internal combustion engine takes effect, the cooling and temperature reduction will be manifested in many aspects of the work process, and the final performance is the reduction of the exhaust gas temperature. When the exhaust gas temperature falls within a certain range, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com