Vanadium dioxide-doped powder and dispersion, and preparation method and application thereof

A technology of vanadium dioxide and dispersion liquid, applied in vanadium oxide, coating and other directions, can solve the problems of low deposition rate, expensive equipment, small film-forming area, etc., and achieve the effects of simple process, low cost and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation of the vanadium dioxide powder of the present invention can use a tetravalent vanadium ion aqueous solution as a reaction precursor, and treat the reaction precursor with an alkaline reagent.

[0049] The configuration of the tetravalent vanadium ion aqueous solution can be prepared by a method commonly used in this field: dissolve the tetravalent soluble vanadium raw material in an appropriate amount of water, preferably deionized water, and the suitable concentration can be 0.005-0.5mol / L, usually 0.01 mol / L L. Quaternary soluble vanadium salts can be commonly used cheap vanadium salts, such as vanadyl sulfate (VOSO 4 ) and vanadium oxychloride (VOCl 2 ). Of course, hydrates of vanadium salts, such as vanadyl oxalate anhydrate (VOC 2 o 4 .5H 2 o). The preparation of the tetravalent vanadium ion solution is usually carried out at normal temperature, but it is also understandable that a little heating or ultrasonication can be used to assist the di...

Embodiment 1

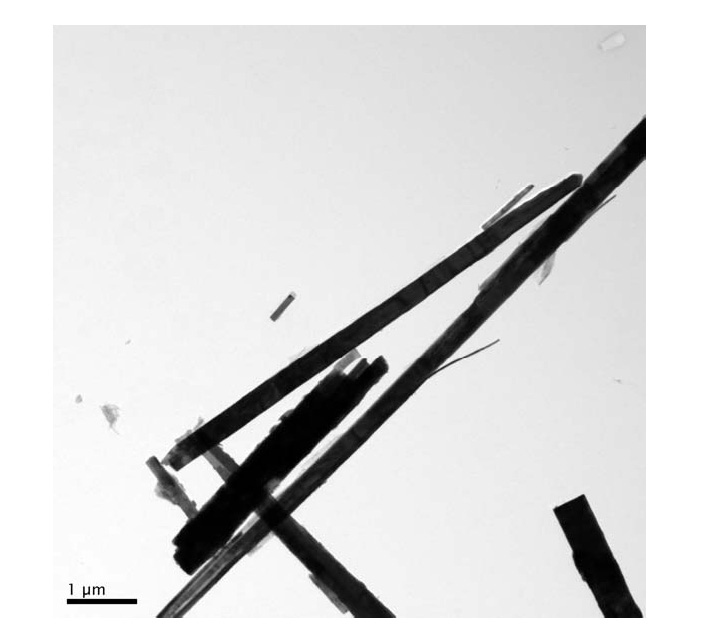

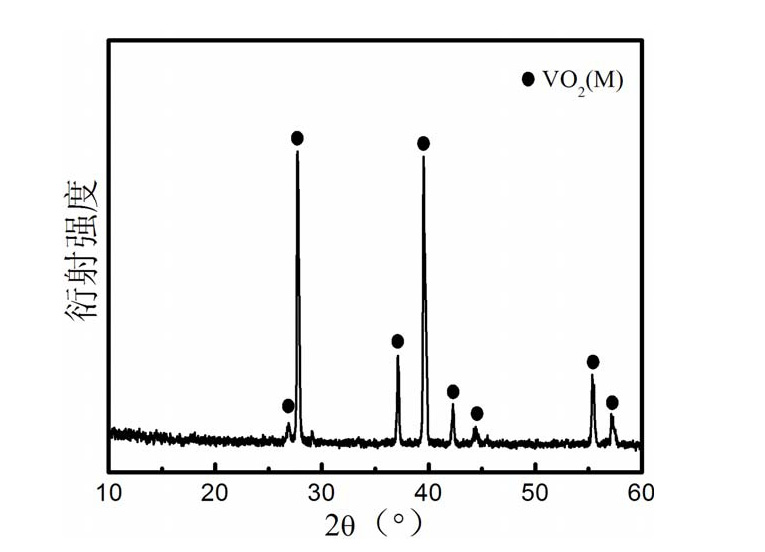

[0068] 1g VOSO 4 Dissolve the powder in 50ml deionized water, titrate with 1 mol / L NaOH solution, and keep stirring, and mix the suspension with 25mg Bi 2 o 3 Put them together into a 50ml hydrothermal kettle filled with 45ml deionized water, conduct a hydrothermal reaction at 250°C for 12 hours, and centrifuge and dry to obtain vanadium dioxide powder. After elemental analysis, its chemical formula is V 0.983 Bi 0.017 o 2 , the yield is 90%. Such as Figure 5 Its crystal phase is M phase as shown in the XRD spectrum, as Figure 6 As shown in the TEM photo, the prepared vanadium dioxide powder is granular, and each vanadium dioxide particle is a single crystal particle, and its grain size is mainly concentrated between 40-50nm, and the aspect ratio is less than 2:1.

Embodiment 2

[0070] With 1g VOSO 4 and 7.5mg Bi 2 o 3 Repeat the experiment of implementing 1 to make vanadium dioxide nanopowder, its chemical formula is V 0.995 Bi 0.005 o 2 , the yield is 85%. Its crystal phase is also M phase, and each vanadium dioxide particle is a single crystal particle, and its grain size is mainly concentrated between 40-70nm, and the aspect ratio is 1:1-3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com