Microbacterium chocolatum and method for preparing (4S,5R)-half ester by using same

A technology of microbacteria and chocolate, which is applied in the direction of bacteria and fermentation, can solve the problems of high cost, insufficient selectivity of pig liver esterase, and restrictions on the large-scale acquisition and use of catalysts, and achieves increased yield, easy preparation, and convenient cultivation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

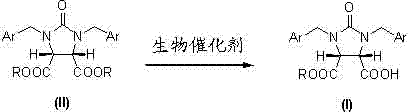

Method used

Image

Examples

Embodiment 1

[0052] Cultivation of Microbacterium chocolate

[0053] Fresh slant medium: glucose 15.0 g / L, yeast extract 5.0 g / L, peptone 10.0 g / L, MgSO 4 1g / L, agar 15-20 g / L, pH 7.0.

[0054] Inclined seed cultivation

[0055] take refrigerator 4 o C preserved Microbacteria chocolate ( Microbacteriumchocolatum ) SIT101 CGMCC NO.4436 strain, after taking it out, inoculate it on the above-mentioned fresh slant medium, at 30 oC cultured for 48 h to obtain Microbacterium chocolate ( Microbacteriumchocolatum ) SIT101 bevel seed, and save it in 4 o C in the refrigerator.

[0056] Fermentation medium: glucose 15.0 g / L, yeast extract 5.0 g / L, peptone 10.0 g / L, MgSO 4 1 g / L, pH 7.0.

[0057] take 4 o C preserved Microbacteria chocolate ( Microbacteriumchocolatum ) SIT101 CGMCC NO.4436 slanted seeds, pick a ring and inoculate into a 250 ml shake flask containing 50 ml fermentation medium, at 30 o C, 160 rpm shaking culture for 48 h, at 10000 g Centrifuge for about 15 min to obtai...

Embodiment 2

[0060] Preparation of meso-dimethyl ester

[0061] The meso-diacid (28.32 g, 0.08 mol), anhydrous methanol (16.2 mL, 0.4 mol),

[0062] Concentrated sulfuric acid (0.4 mL, 7.5 mmol) and benzene (65 mL) were heated to reflux for 6 h with stirring. The solvent was removed under reduced pressure, and water (40 mL) and ethyl acetate (40 mL) were added to the residue. After the organic phase was separated, the aqueous phase was extracted three times with ethyl acetate (10 mL). Combine the ethyl acetate phases and wash with 2 M Na 2 CO 3 (3 times in total, 5 ml each time) and water (4 times in total, 5 ml each time) to wash. Afterwards, it was dried with anhydrous sodium sulfate, and the solvent was removed under reduced pressure to obtain meso-dimethyl ester (II), with a yield of about 92% and a purity of 99%.

[0063] Get the microbacteria chocolate ( Microbacteriumchocolatum ) SIT101 resting cells, suspended in 9.5ml sodium phosphate buffer solution (0.1 M, pH 8.0), adding...

Embodiment 3

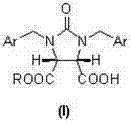

[0065] Get the microbacteria chocolate ( Microbacteriumchocolatum ) SIT101 resting cells, suspended in 9.5 ml of sodium phosphate buffer solution (0.1 M, pH 8.0), adding 0.1 mmol of meso-dimethyl ester obtained in the example, and then adding 0.5 ml of methanol, and the reaction mixture was heated at 30° C, 160 r / min shaking reaction on a constant temperature shaking table, intermittent sampling is extracted with ethyl acetate, and the enantiomeric excess value and the productive rate of the product are analyzed by chiral liquid chromatography. After reacting for 24 hours, (4 S , 5 R )-hemimethyl ester in a yield of 87% with an enantiomeric excess (e.e.) greater than 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com