Automobile tail gas three-way catalytic converter system and control method thereof

A catalytic converter and automobile exhaust technology, which is applied in the field of automobile exhaust three-way catalytic converter systems, can solve the problems of aggravating the growth, sintering and aggregation of precious metal active components, and decreasing the activity of catalysts, so as to improve the cold-start conversion efficiency. , the effect of improving life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

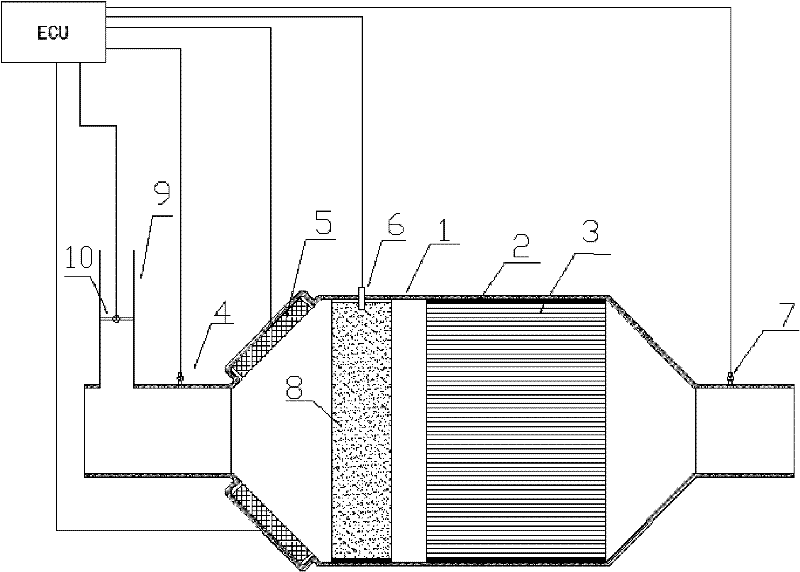

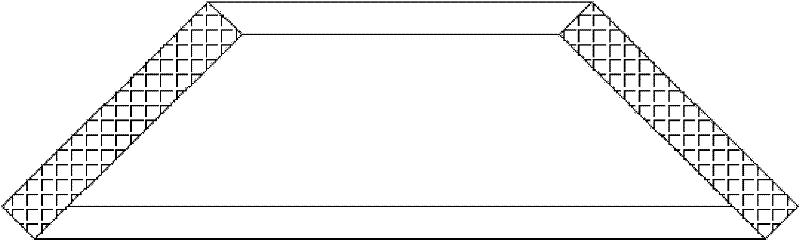

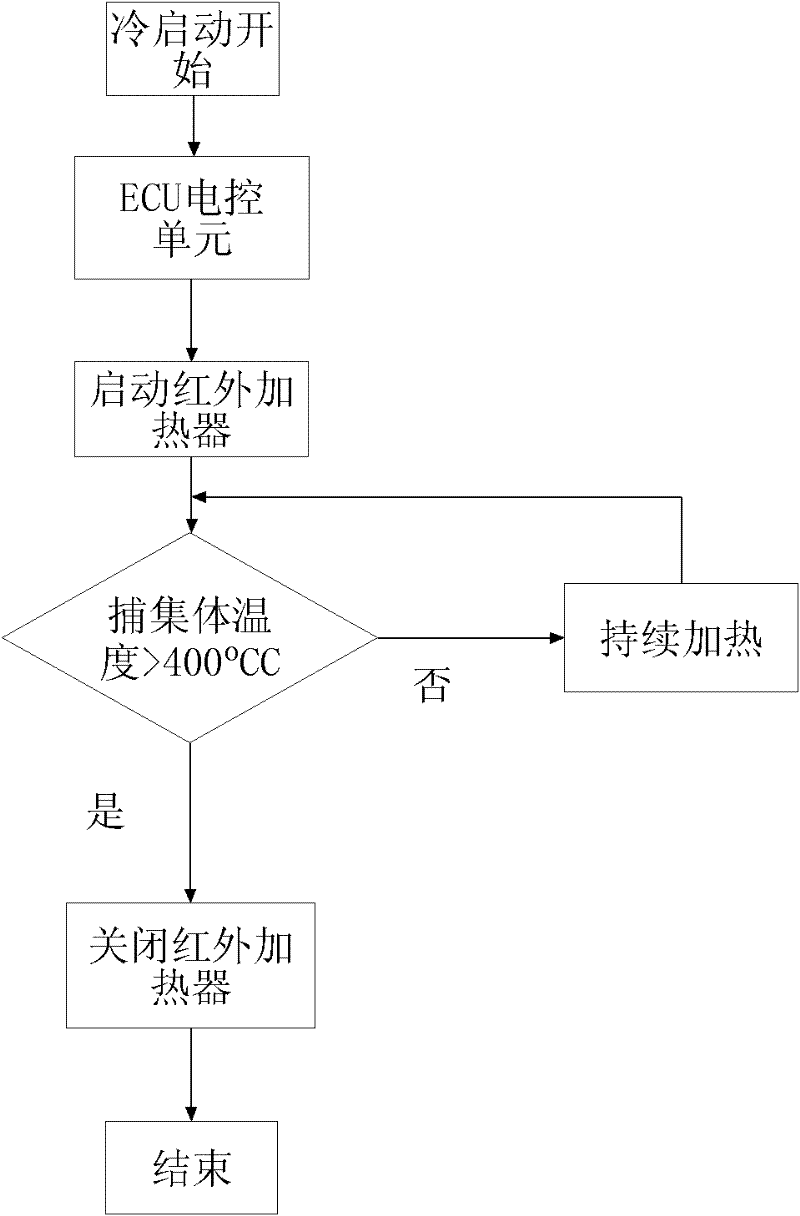

[0019] Such as figure 1 Shown, the automobile tail gas three-way catalytic converter system of the present invention comprises automobile ECU and housing 1, metal foam catch body 8; Housing 1 ( figure 1 From left to right in the middle) is composed of intake section, expansion section, main section, contraction section, and exhaust section. The honeycomb ceramic structure carrier 3 is installed at the rear of the main section inner cavity and between the honeycomb ceramic structure carrier 3 and the main section. A damping layer 2 is provided; a metal foam trap body 8 coated with an infrared coating material on the surface is installed in the front part of the main body cavity, and an air bypass pipe 9 with one end connected to the atmosphere is provided in the air intake section, and the air bypass pipe 9 There is a proportional bypass valve 10 in which the electrode terminal is connected to the automobile ECU; the annular infrared heater 5 is nested in the expansion section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com