Preparation method of gamma-aminobutyric acid coated when passing rumen

An aminobutyric acid, rumen-passing technology, applied in the molding or processing of animal feed, animal feed, additional food elements, etc., can solve problems such as limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

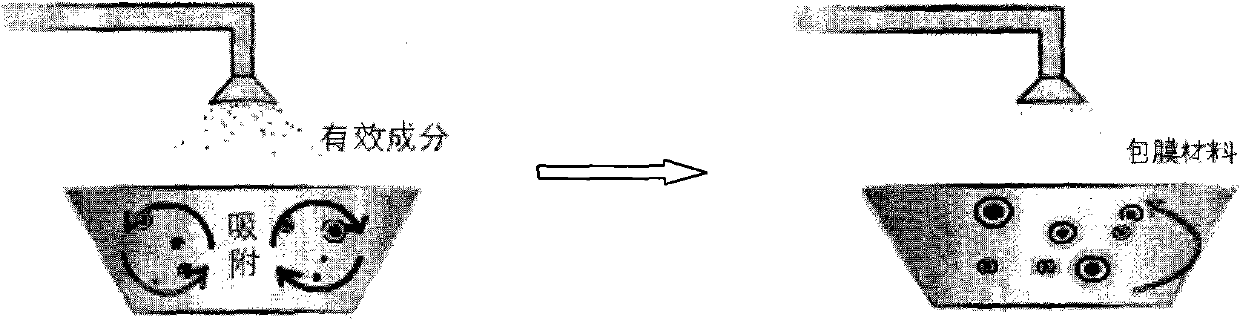

Method used

Image

Examples

Embodiment 1

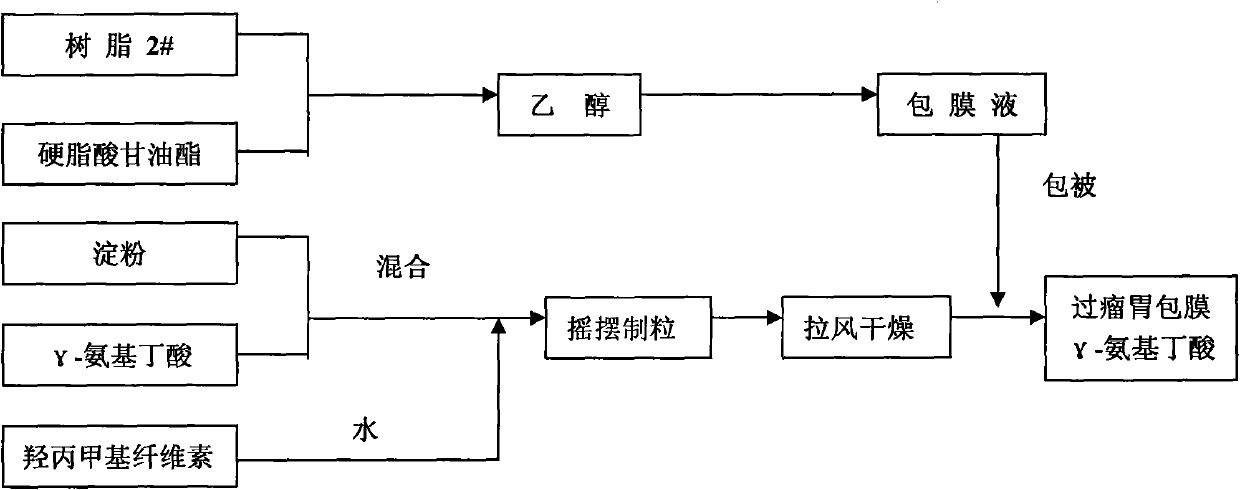

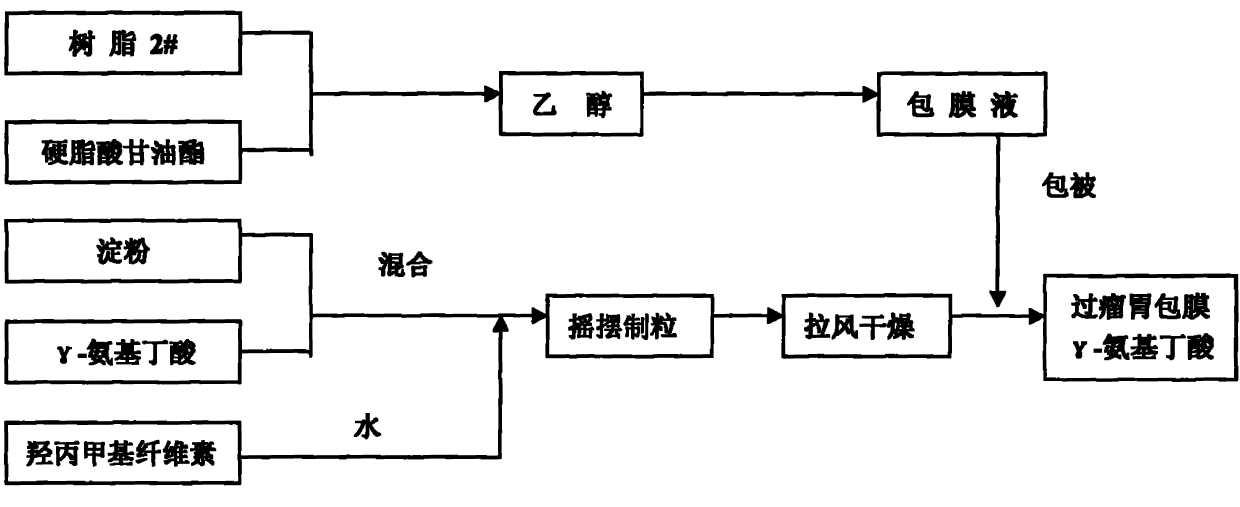

[0016] Weigh and weigh 500g of starch and 8000g of γ-aminobutyric acid powder, stir at 30-90rpm for 20min to mix evenly; weigh 500g of hydroxypropylmethylcellulose and dissolve in 10000mL of water to obtain 5% hydroxypropylmethylcellulose Add the above hydroxypropyl methylcellulose solution to the mixture of starch and γ-aminobutyric acid, granulate with shaking, and dry by pulling the wind. Add 500g of glyceride and 500g of resin 2# into 21000mL ethanol solution to fully dissolve it as coating solution; in the coating equipment, the flow rate is 0.1L / min, the inlet air temperature is 50-60℃, the outlet air temperature is normal temperature, and the time is 3.5 h, carry out coating treatment. More than 85% of the product particle size passes through a 20-mesh sieve.

Embodiment 2

[0018] Weigh and weigh 2000g of starch and 5000g of γ-aminobutyric acid powder, and stir for 20min at a speed of 30-90rpm to mix evenly; weigh 1000g of hydroxypropylmethylcellulose and dissolve it in 10000mL of water to obtain 10% hydroxypropylmethylcellulose Add the above hydroxypropyl methylcellulose solution to the mixture of starch and γ-aminobutyric acid, granulate with shaking, and dry by pulling the wind. Add 1,500g of glyceride and 500g of resin 2# into 21,000mL of ethanol solution and fully dissolve it as a coating solution; in the coating equipment, the flow rate is 0.1L / min, the inlet air temperature is 50-60°C, and the outlet air temperature is normal temperature, and the time is 3.5 h, carry out coating treatment. More than 85% of the product particle size passes through a 20-mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com