Nanogold modified enhanced up-conversion luminescence composite material and preparation method thereof

A technology of composite materials and nanomaterials, which is applied in the field of nano-gold modified enhanced up-conversion luminescent composite materials and its preparation, can solve the problems of low up-conversion luminous efficiency, achieve significant economic value and application value, improve luminous efficiency, easily detectable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

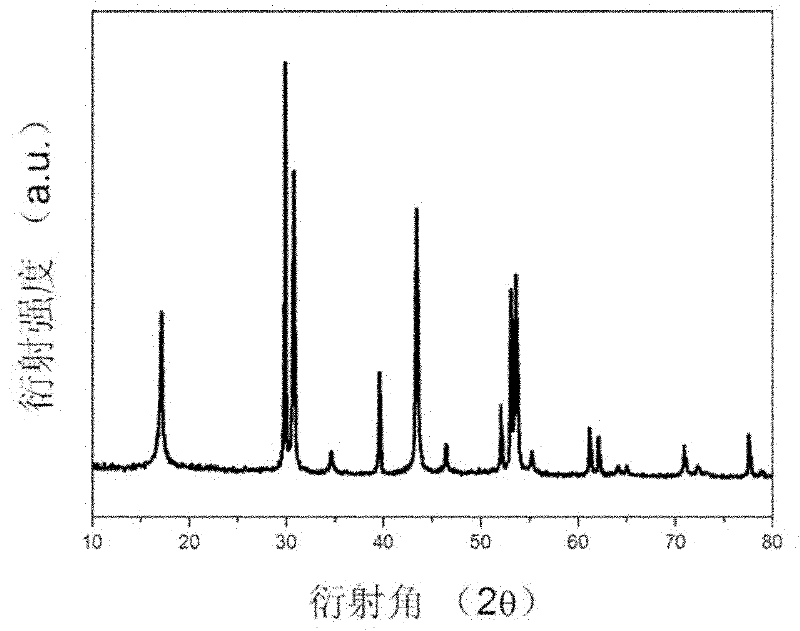

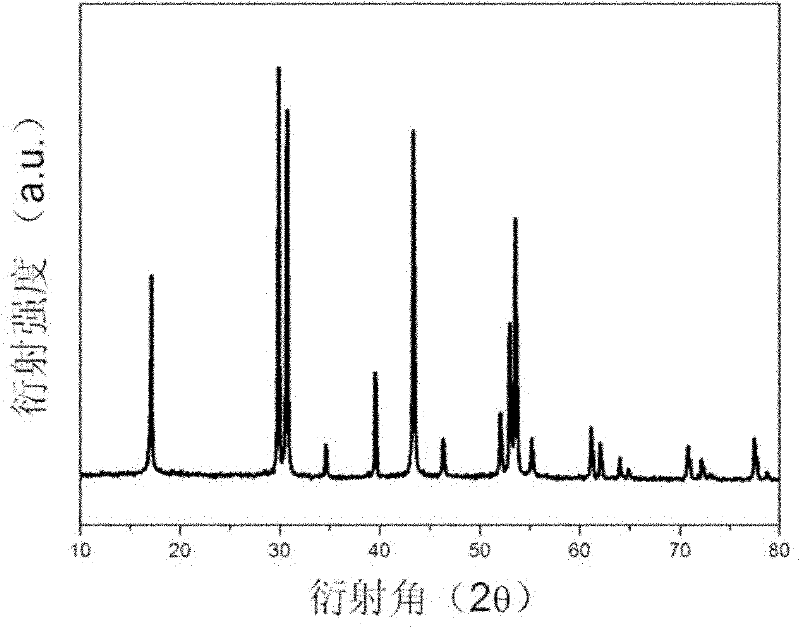

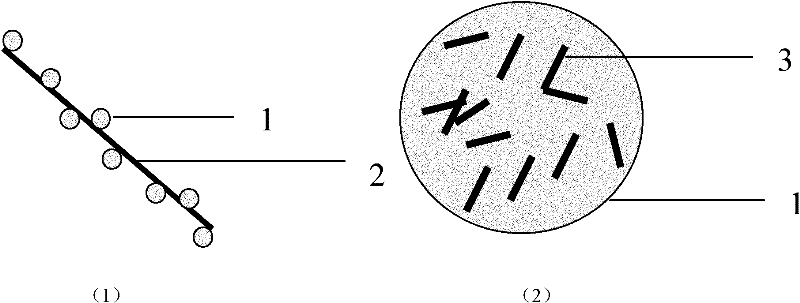

[0033] First dissolve Y with nitric acid 2 o 3 、Tm 2 o 3 , Yb 2 o 3 The corresponding nitrate solution was obtained. Add 4mmol sodium citrate and 10ml water into a 60ml reaction flask and stir evenly, then add 0.8mmol Y(NO 3 ) 3 , 0.2mmol Yb(NO 3 ) 3 , 0.005mmol Tm (NO 3 ) 3 Add it, continue magnetic stirring for 0.5 hours, then add 0.2519g NaF at one time and continue stirring for 2 hours, then transfer the mixed solution into a 20ml reaction kettle, and react at 180°C for 12 hours. Naturally cool to room temperature after the reaction is over, take out the reaction solution and centrifuge, pour out the supernatant, wash with distilled water and centrifuge again, repeat 3 times, then wash with 3mmol / L sodium citrate solution and centrifuge 3 times again, to obtain the obtained NaYF required 4 :Yb 3+ , Tm 3+ nano core.

[0034] In the three-neck flask, at 99°C, add the obtained 1mmol NaYF 4 :Yb 3+ , Tm 3+ Nuclei and 60ml of sodium citrate solution with a conc...

Embodiment 2

[0036] First dissolve Y with nitric acid 2 o 3 、Tm 2 o 3 , Yb 2 o 3 The corresponding nitrate solution was obtained. Add 6mmol sodium citrate and 10ml water into a 60ml reaction flask and stir evenly, then add 0.8mmol Y(NO 3 ) 3 , 0.2mmol Yb(NO 3 ) 3 , 0.005mmol Tm(NO 3 ) 3 Add it, continue magnetic stirring for 0.5 hours, then add 0.3359 g of NaF at one time, continue stirring for 2 hours, transfer the mixture into a 20ml reaction kettle, and react at 180°C for 12 hours. Naturally cool to room temperature after the reaction is over, take out the reaction solution and centrifuge, pour out the supernatant, wash with distilled water and centrifuge again, repeat 3 times, then wash with 3mmol / L sodium citrate solution and centrifuge 3 times again, to obtain the obtained NaYF required 4 :Yb 3+ , Tm 3+ nano core.

[0037] In the three-neck flask, at 99°C, add the obtained 1mmol NaYF 4 :Yb 3+ , Tm 3+ core and 60ml of sodium citrate solution with a concentration of 0...

Embodiment 3

[0039] First dissolve Y with hydrochloric acid 2 o 3 、Tm 2 o 3 , Yb 2 o 3The corresponding chloride salt solution is obtained. Add 8mmol sodium citrate and 10ml water into a 60ml reaction bottle and stir evenly, then add 0.8mmol YCl 3 , 0.2 mmol YbCl 3 , 0.005 mmol TmCl 3 Add it, continue magnetic stirring for 0.5 hours, then add 0.3359 g of NaF at one time, continue stirring for 2 hours, transfer the mixed solution into a 20ml reaction kettle, and react at 180°C for 12 hours. Naturally cool to room temperature after the reaction is over, take out the reaction solution and centrifuge, pour out the supernatant, wash with distilled water and centrifuge again, repeat 3 times, then wash with 3mmol / L sodium citrate solution and centrifuge 3 times again, to obtain the obtained NaYF needed 4 :Yb 3+ , Tm 3+ nano core.

[0040] In the three-neck flask, at 99°C, add the obtained 1mmol NaYF 4 :Yb 3+ , Tm 3+ core and 60ml of sodium citrate solution with a concentration of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com