Slow sinking type puffing aquatic product matched pellet feed, application, producing method and equipment thereof

A technology of pellet feed and manufacturing equipment, which is applied in the field of fish feed, can solve the problems of lowering the qualified rate of finished products, increasing the cost, fish stress disease, etc., and achieves the effects of reducing feed waste, reducing production cost and high feed remuneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

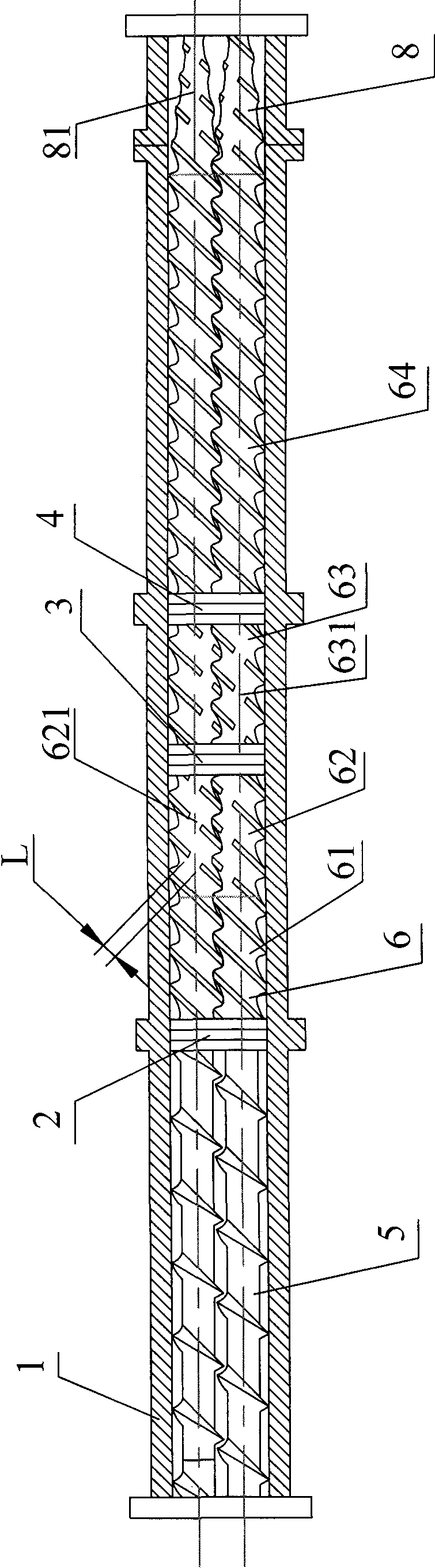

[0059] Embodiment 1. A manufacturing equipment for slow-sinking extruded aquatic product compound pellet feed, comprising a pulverizer, a mixer, a conditioner, a twin-screw extruder, a granulator and a dryer connected in sequence. Pulverizers, mixers, conditioners, granulators and dryers are all conventional equipment.

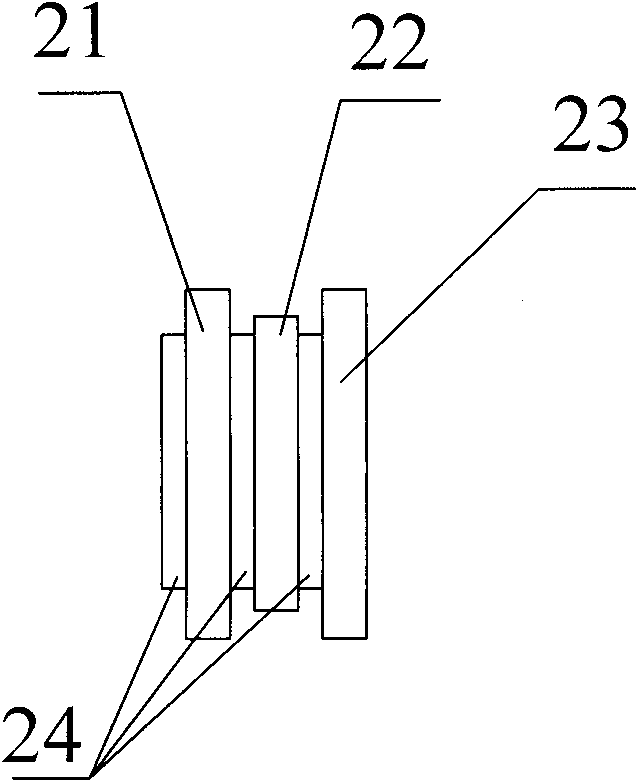

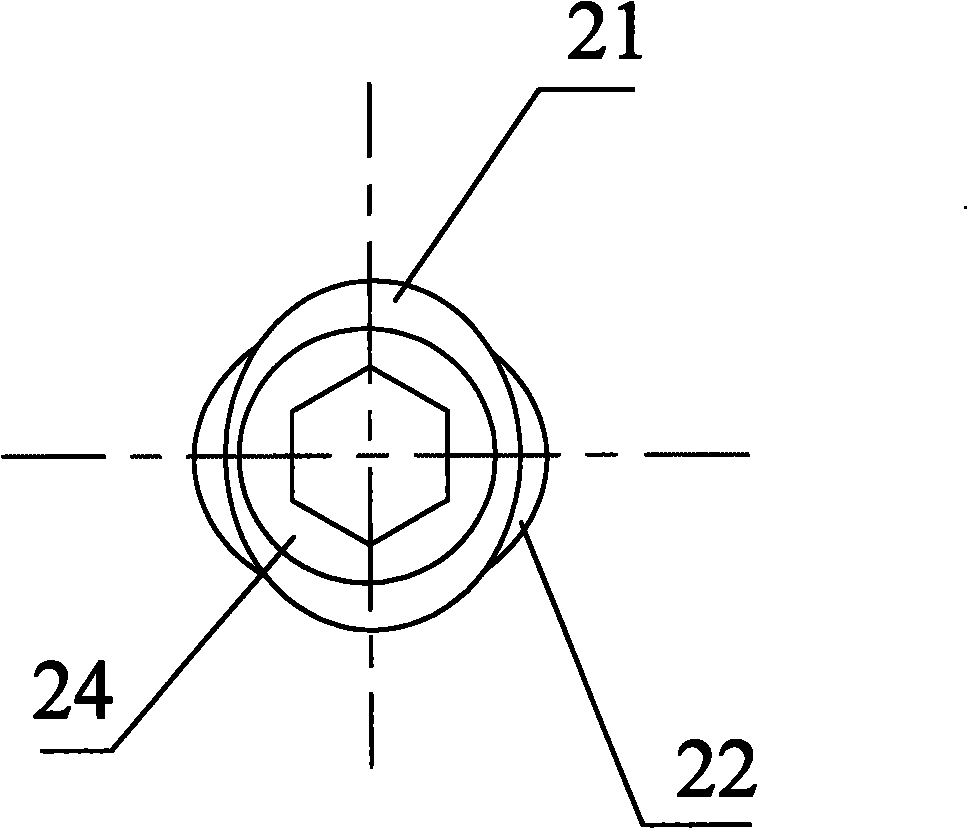

[0060] The twin-screw extruder includes a shell 1, on which a cooling water channel and a steam channel are provided, and on the shell 1 there is also a vent hole communicating with the inner cavity of the shell 1, and in the inner cavity of the shell 1 There are 2 sets of screw assemblies with the same direction of rotation and the same speed, and a regular hexagonal rotating shaft is installed in each set of screw assemblies. The rotating shaft is connected with the gear box, and the gear box is connected with the motor. The volume of the puffing chamber is 0.031m 3 . Center-to-center distance between 2 rotating shafts = 96mm.

[0061] The screw assembly ...

Embodiment 2

[0087] Embodiment 2, a kind of manufacturing method of the slow-sinking type extruded aquatic product compound pellet feed for California perch, carries out the following steps successively:

[0088] 1) Ingredients

[0089] Weigh 55% of fish meal, 8% of by-products of shrimp (crab) processing, 8% of soybean meal, 5% of beer yeast, 1.7% of calcium dihydrogen phosphate, 3.5% of vitamin and mineral premix, and 8% of high-gluten flour. %, lecithin oil 2%, fish oil 8%, bamboo leaf flavonoids 0.15%, capillary 0.35%, apocynum 0.15%, Bupleurum 0.15%.

[0090] It is known through routine testing that the total carbohydrates account for 10% and the crude fat accounts for 18% in the California sea bass feed formula.

[0091] 10% of carbohydrates mainly come from high-gluten flour and soybean meal, and 18% of crude fat mainly comes from fish meal and fish oil.

[0092] 2) Smash

[0093] Mix fish meal, by-products of shrimp (crab) processing, soybean meal, beer yeast, calcium dihydrogen...

Embodiment 3

[0124] Embodiment 3, a kind of manufacturing method of the slow-sinking type extruded aquatic product compound pellet feed for snakeheaded fish, the following steps are carried out successively:

[0125] 1) Ingredients

[0126] Weigh 58% fish meal, 12% soybean meal, 4% brewer's yeast, 1.5% calcium dihydrogen phosphate, 4% vitamin and mineral premix, 8.5% high-gluten flour, 2.5% lecithin oil, 7.5% fish oil , Chinese herbal medicine additive 2%.

[0127] After testing, the total carbohydrates accounted for 13% and the crude fat accounted for 16.5% in the snakehead fish feed formula.

[0128] 2) Smash

[0129] Mix fish meal, soybean meal, brewer's yeast, calcium dihydrogen phosphate, vitamin and mineral premix, and high-gluten flour for the first time. The mixing time is 120-180 seconds, and then crushed to make it pass through 40-60 mesh screen;

[0130] Put the crushed material above into a vertical sieveless superfine pulverizer for superfine pulverization, so that the finen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com