Method for optimizing parameter of high phosphorus iron ore smelting process

A process parameter optimization, high-phosphorus iron ore technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as threats to health and life safety, inability to observe dynamic changes, and unusable crucibles. Achieving the effect of high practical value, simple and feasible method and less consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The specific method is: (1) put samples with different ratios (or the particle size of mineral powder, carbon ratio, temperature) on a thermogravimetric analyzer for kinetic experiments; (2) obtain differential heat at regular intervals Scanning calorimetric data; (3) Make a time series table of the obtained data and put it into the software used for analysis; (4) Judge the smelting effect according to the image features, so as to determine the optimal process parameters.

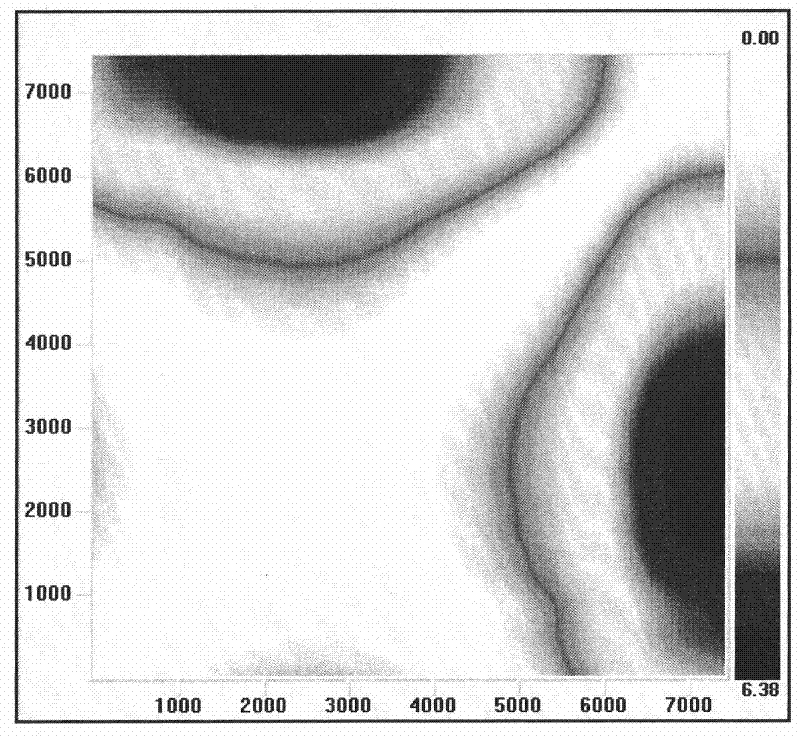

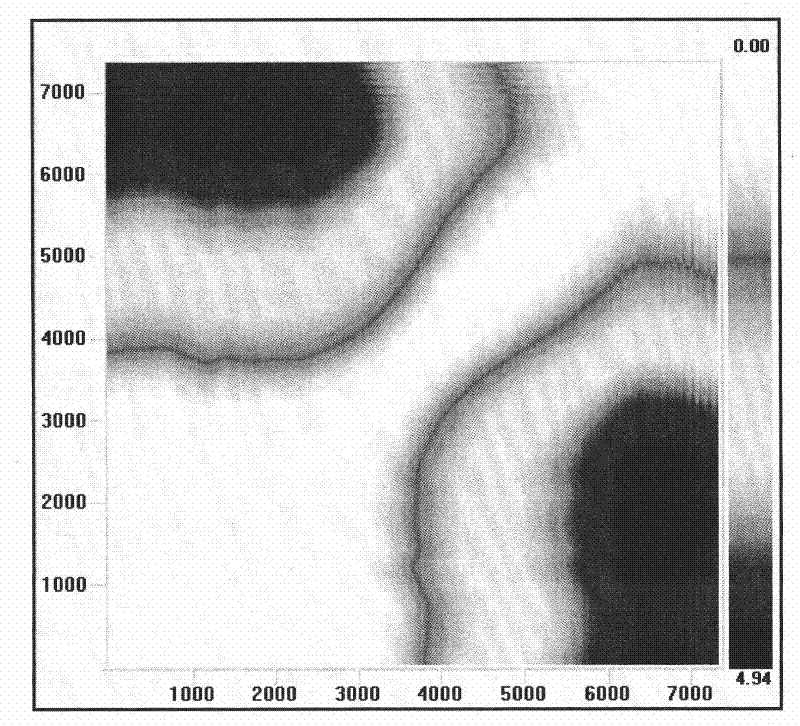

[0032] The selection of alkalinity in the smelting of a high phosphorus iron ore, the range of alkalinity is 0.8, 1.1, 1.4, 1.7, 2.0. After proportioning, the thermogravimetric experiment was used for analysis. The experimentally obtained differential thermal scanning calorimetry data is made into a dynamic map with VRA software (such as Figure 1-5 ). It is found that when the alkalinity is 1.1 to 1.4, the clouds are concentrated and symmetrical along the upper left and lower right diagonals. The ...

Embodiment 2

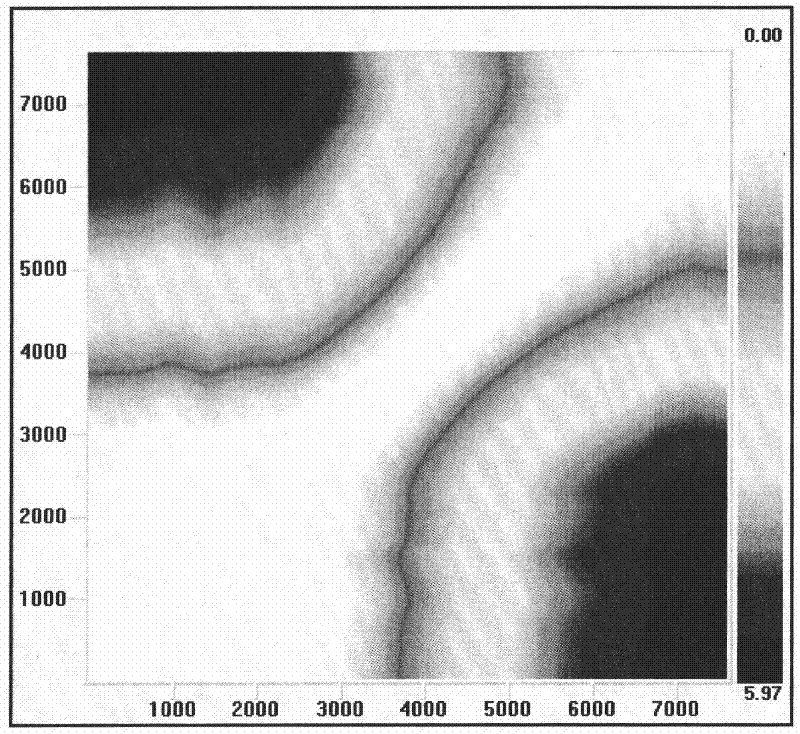

[0034] The selection of the optimum melting temperature in the smelting of a high phosphorus iron ore ranges from 1350°C, 1400°C, 1450°C, 1500°C, 1550°C. After proportioning, use thermogravimetric experiment to carry out isothermal analysis. The experimentally obtained differential thermal scanning calorimetry data is made into a dynamic map with VRA software (such as Figure 6-10 ). It is found that at 1450°C, the cloud color is concentrated and symmetrical along the upper left and lower right diagonal lines. The actual muffle furnace experiment also proves that the slag-iron phase is evenly distributed at around 1450°C (known by scanning electron microscope morphology analysis) . VRA software is existing software, we just use this software for analysis.

[0035] The invention is applied to the optimization of smelting parameters, the method is simple and convenient, and has high practical value, and provides a reliable and practical experimental optimization method for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com