High speed line parallel image sensor oriented to real-time vision chip

An image sensor and real-time vision technology, applied in the direction of image communication, color TV parts, TV system parts, etc., can solve the problems of insufficient speed, poor embedding, limiting system speed, etc., and achieve low cost and high integration , Improve the effect of sampled image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

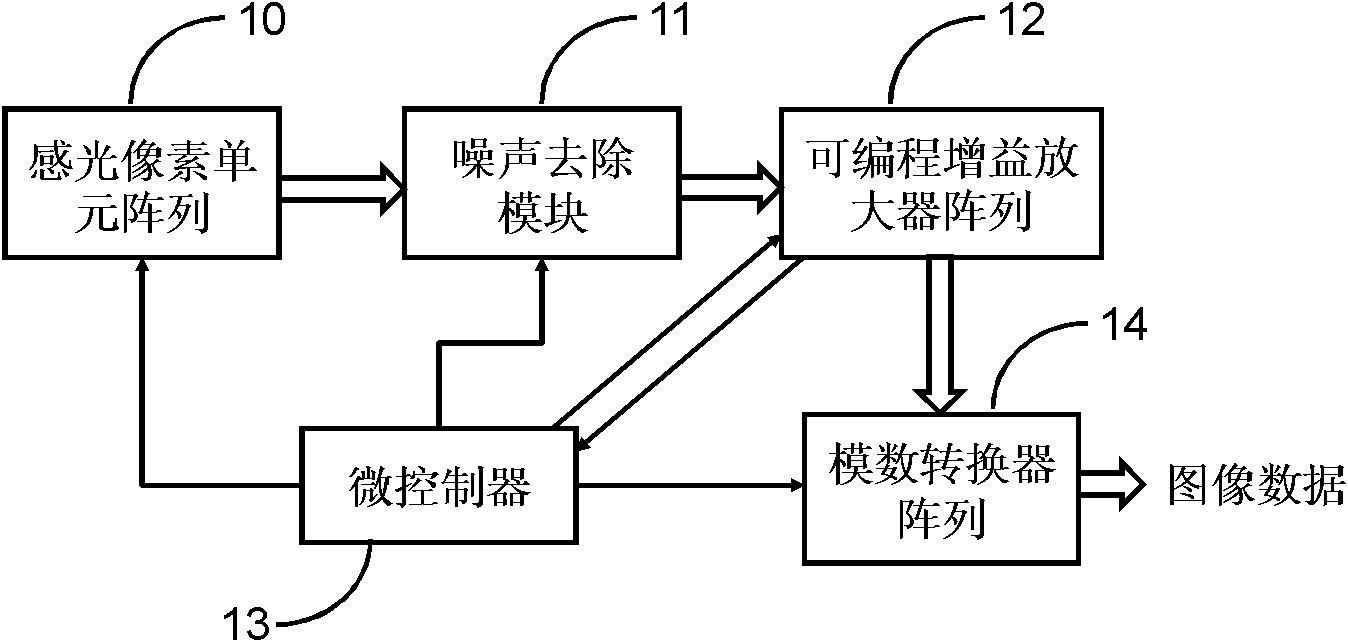

[0031] see figure 1 As shown, the present invention provides a kind of high-speed line parallel image sensor facing real-time vision chip, comprising:

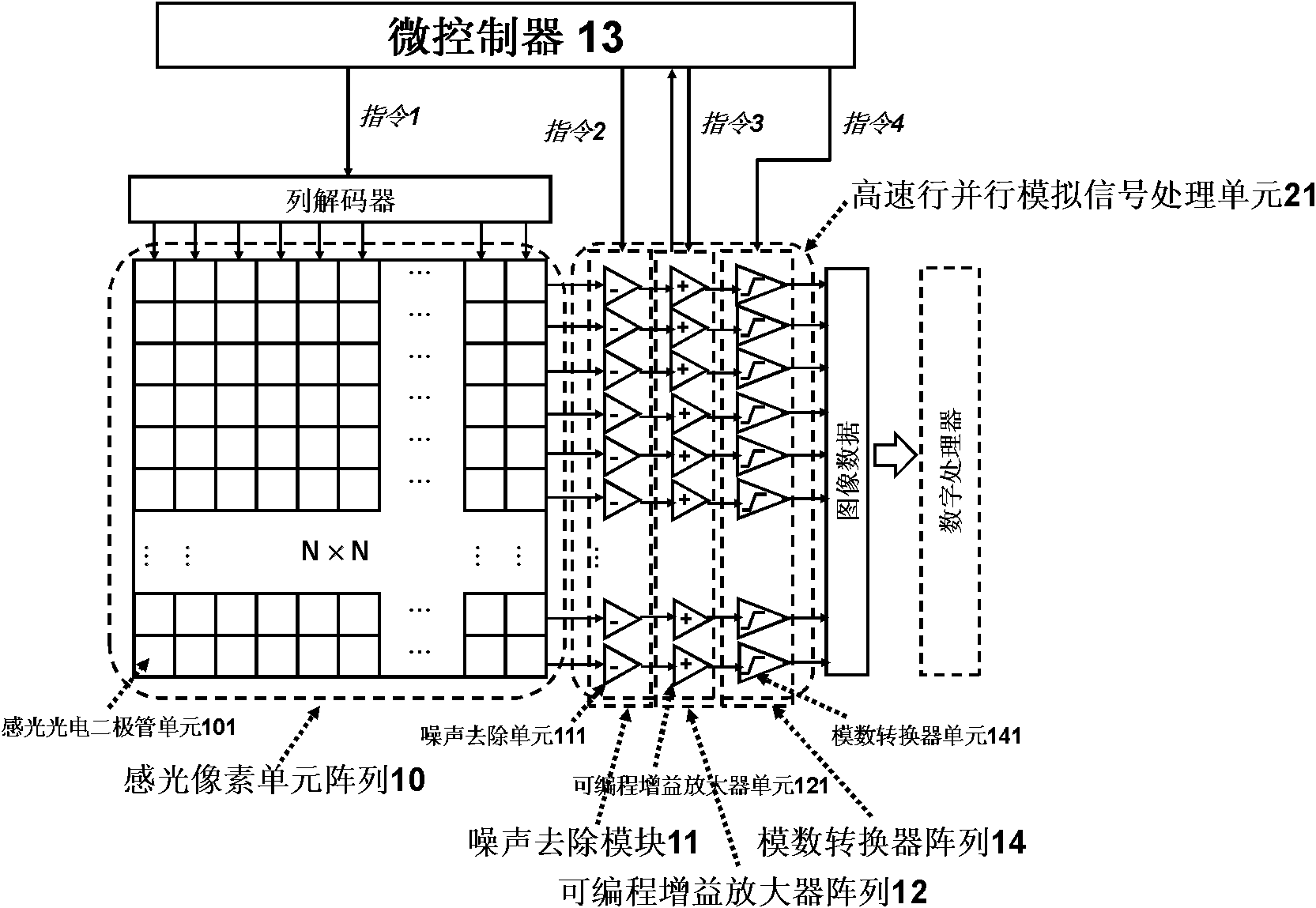

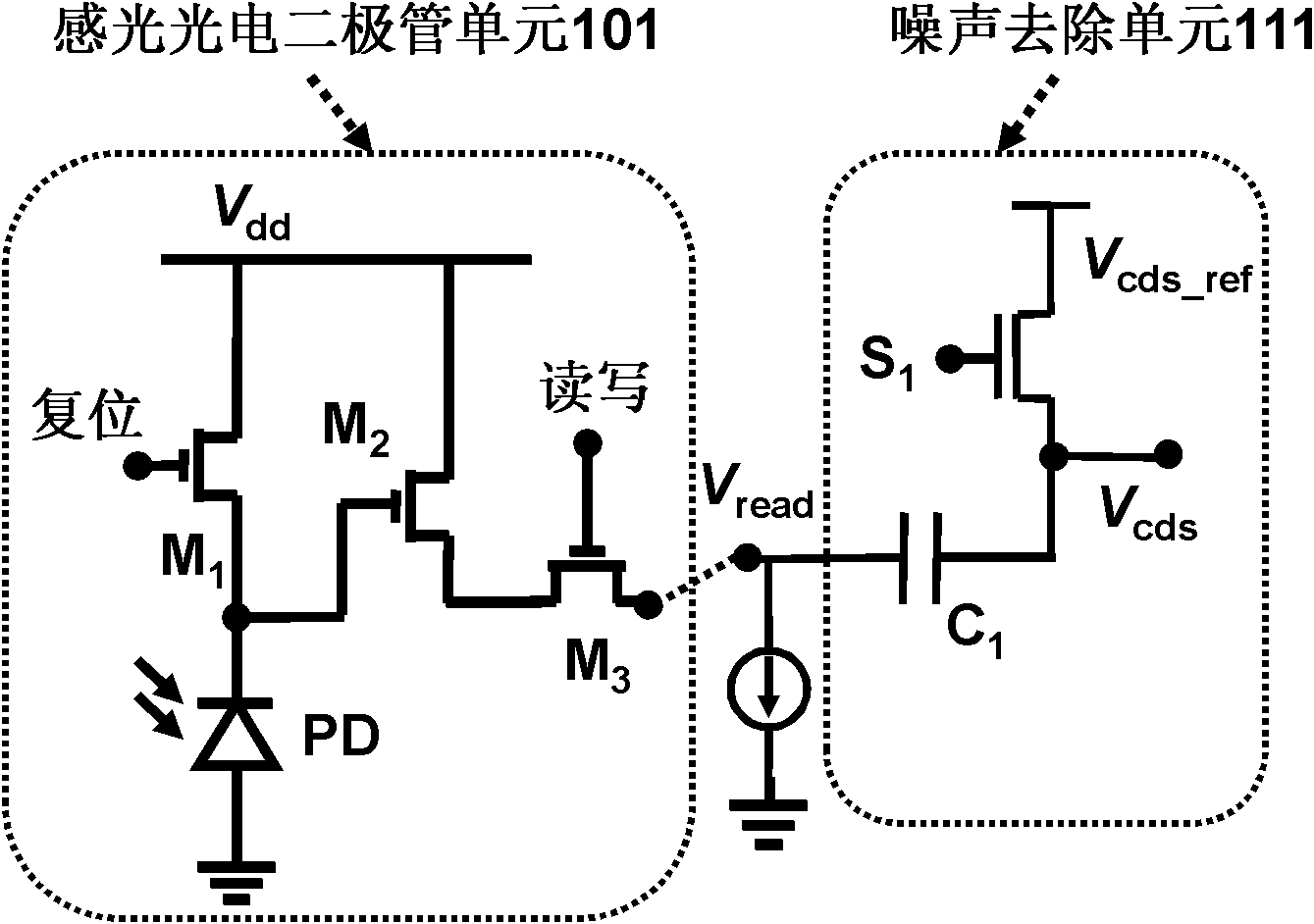

[0032] A photosensitive pixel unit array 10, used to collect the original information of the incident light, and convert the collected target image light signal into an electrical signal; the photosensitive pixel unit array 10 is composed of photosensitive photodiode units 101, each photosensitive photodiode The unit 101 is composed of a photosensitive photodiode part and a readout circuit part, and the photosensitive photodiode part is composed of a photodiode layer of a standard CMOS process, which is used to obtain higher light sensitivity at a lower cost; based on figure 1 The system block diagram of the high-speed line parallel image sensor facing the real-time vision chip, figure 2 The present invention provides a system structure diagram of a high-speed line-parallel image sensor oriented to a real-time vision chip, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com