High-throughput polyamide reverse osmosis composite membrane

A reverse osmosis composite membrane and polyamide technology, applied in reverse osmosis, semi-permeable membrane separation, osmosis/dialysis water/sewage treatment, etc. The effect of high water content and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

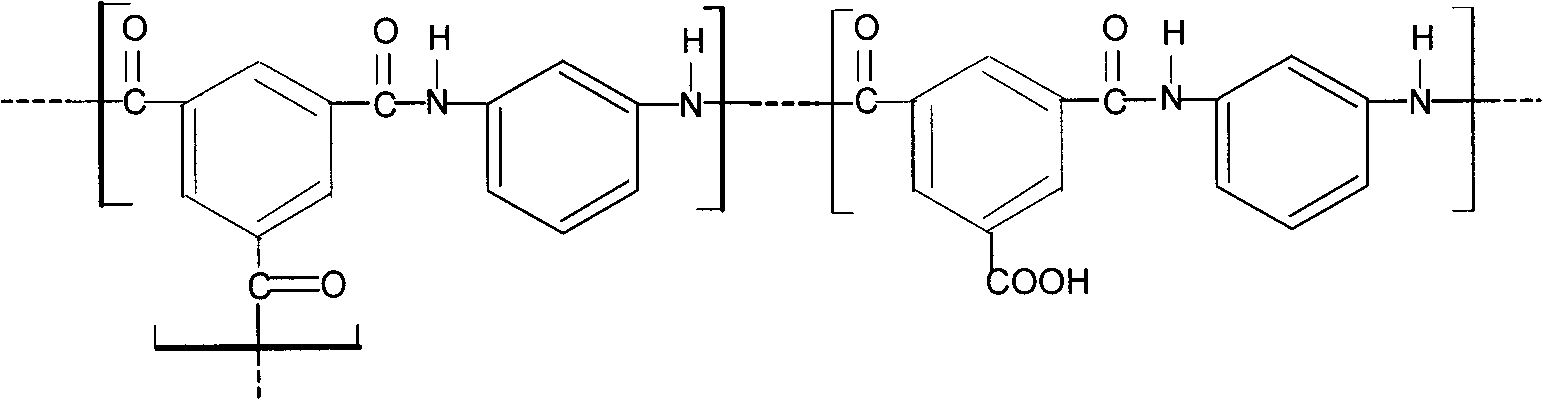

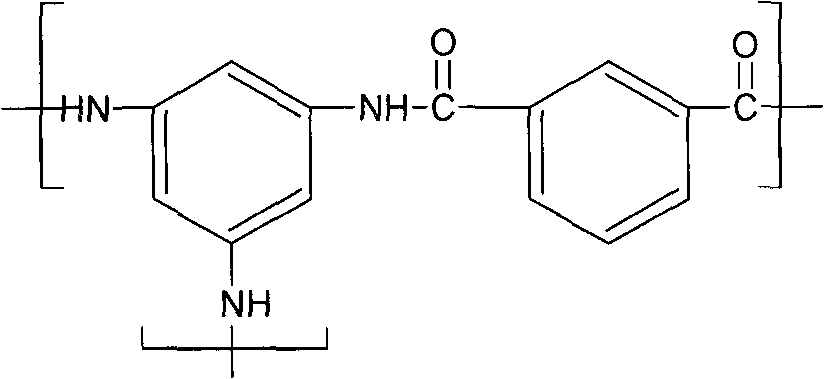

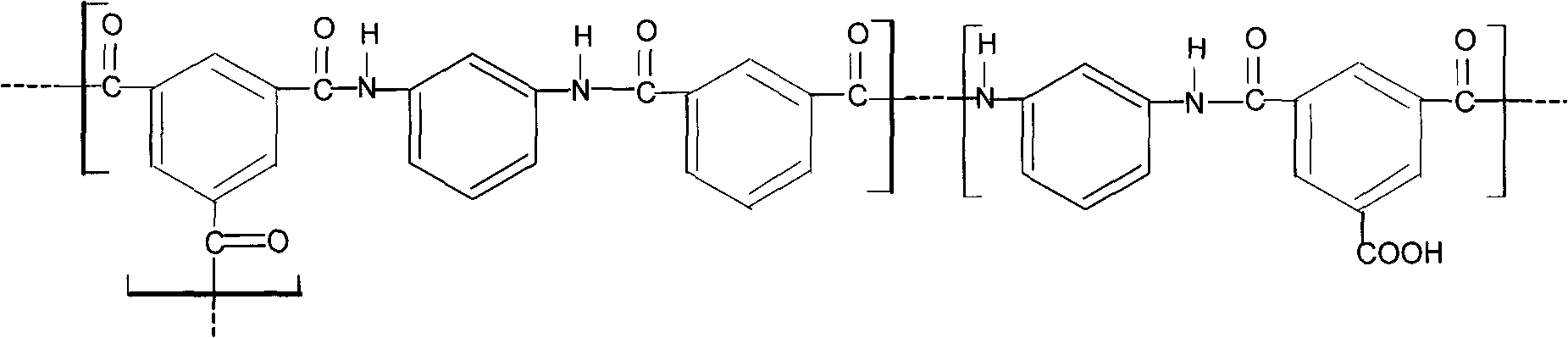

Image

Examples

Embodiment 1-8

[0042] Use 13.5wt% Udel PS3500 polysulfone, 0.2wt% water and 0.1wt% nonylphenol polyoxyethyl ester phosphate dissolved in N,N-dimethylformamide, and scrape on the polyester non-woven fabric , and then immersed in water to remove the solvent to obtain a porous support membrane with a molecular weight cut-off of 100,000-120,000, which is stored in a wet state for future use.

[0043] Immerse one side of the wet polysulfone porous support membrane into aromatic polyamines (respectively m-phenylenediamine, or 4-chloro-m-phenylenediamine, or 4-nitro-m-phenylenediamine, or 2,4-di Aminotoluene) and aliphatic macromolecular polyamine polyamine polyethyleneamine (molecular weight = 30,000; degree of ammonolysis a = 0.52) in an aqueous solution with a total content of 2.0 wt% for 4 minutes, use a rubber roller to roll the surface of the support film, and drain the aqueous solution After drying the surface of the support film with nitrogen, contact with 0.08wt% trimesoyl chloride (TMC) n...

Embodiment 9-14

[0047] As in the preceding examples, according to the method described above, an aqueous solution with a total content of 2.4 wt% of m-phenylenediamine and polyvinylamine (molecular weight=30,000; degree of ammonolysis a=0.52) and 0.05 wt% of aromatic multi-acid chloride ( Trimesoyl chloride (TMC), or 5-isocyanate-isophthaloyl chloride (ICIC), or 5-oxoformyl chloride-isophthaloyl chloride (CFIC)) in n-heptane to prepare reverse osmosis composite membranes. These several examples are to investigate the effect of adding aliphatic macromolecular polyamine polyamine on the properties of films formed from different polybasic acid chlorides.

[0048]

[0049] The above examples show that: adding aliphatic macromolecular polyamine polyvinylamine to the aqueous phase solution of aromatic polyamines can significantly improve the reverse osmosis composite rate formed by different polyacyl chlorides under the premise of keeping the membrane desalination rate almost unchanged. membrane...

Embodiment 15-21

[0051] As in the previous examples, according to the above method, the total content of m-phenylenediamine and polyvinylamine (molecular weight=30,000; degree of ammonolysis a=0.52) is 1.2wt%, and different m-phenylenediamine and polyvinylamine weight ratios are used. aqueous solution, and 0.12wt% trimesoyl chloride (TMC) n-heptane solution to prepare a reverse osmosis composite membrane. These several examples are to investigate the effect of the weight ratio of aromatic polyamines and aliphatic macromolecular polyamines in the aqueous phase solution on the film-forming properties.

[0052] Example

[0053] The above examples show that a high-flux reverse osmosis composite membrane can be obtained by adding aliphatic macromolecular polyamine polyvinylamine to the aqueous phase solution of aromatic polyamine, but too high polyvinylamine content will lead to a decrease in membrane desalination rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com