Water-based acrylic finish paint and preparation method thereof

A water-based acrylic and topcoat technology, applied in coatings and other directions, can solve problems such as difficulty in meeting the requirements of long-term anti-corrosion systems, and achieve the effects of outstanding freeze-thaw stability, strong weather resistance, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

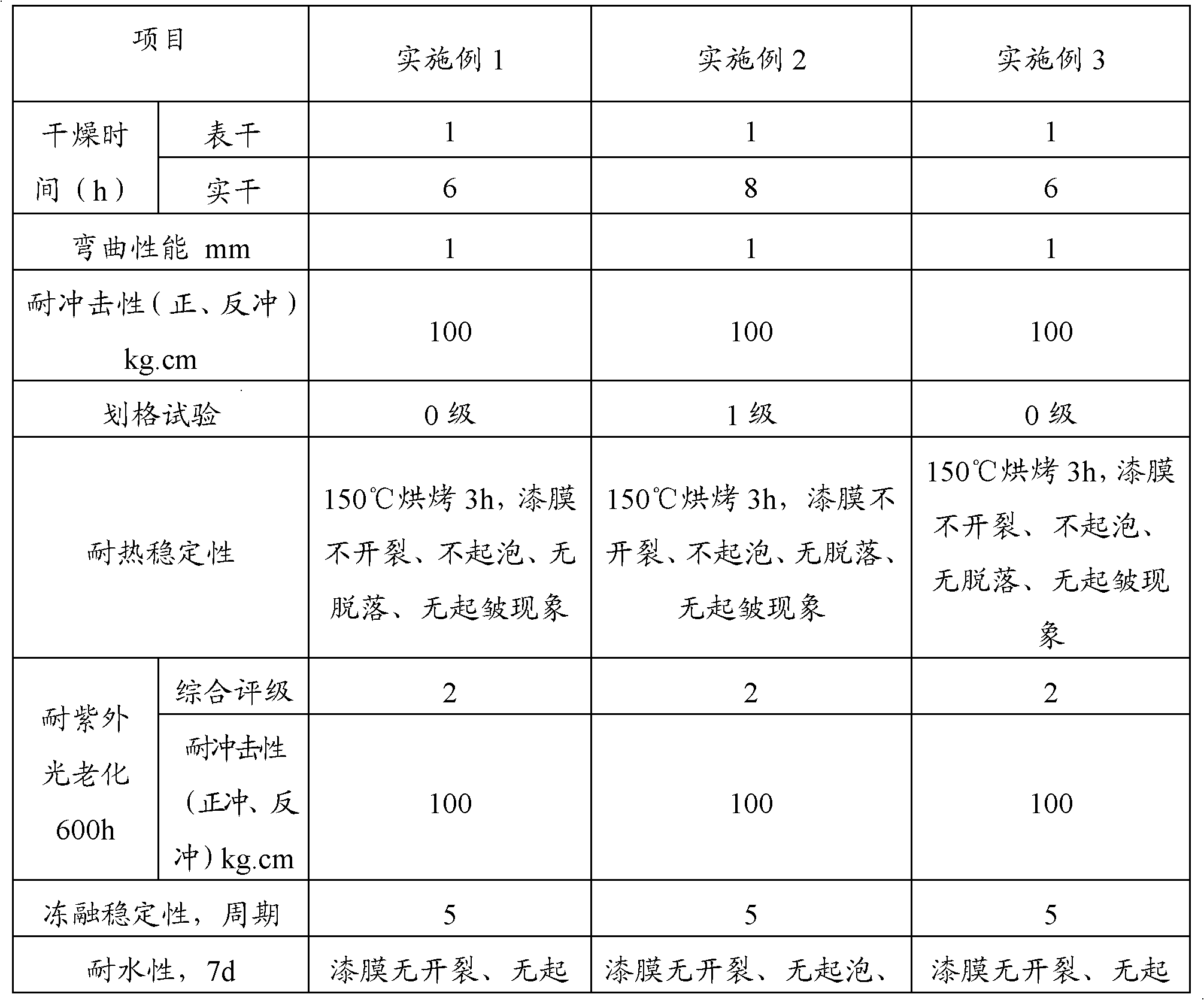

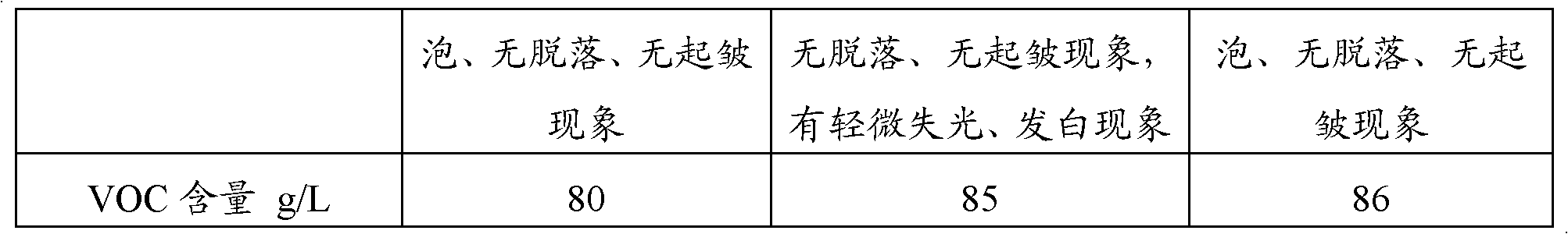

Examples

preparation example Construction

[0049] The preparation method of waterborne acrylic topcoat provided by the invention may further comprise the steps:

[0050] a) Weigh deionized water, dispersant, pigments and fillers, pH regulator and thixotropic agent in proportion, mix and stir evenly at a speed of 1200 rpm to 1800 rpm, and then grind, preferably until the fineness is ≤40 μm ;

[0051] b) Add water-based acrylic resin, defoamer, substrate wetting agent, flash corrosion inhibitor, film-forming aid and light stabilizer in proportion to the mixture obtained in the previous step and stir at a speed of 1000 rpm to 1500 rpm / min;

[0052] c) filtering the mixture obtained in b) to remove impurities;

[0053] d) adjusting the pH of the mixture to 8-9 with an appropriate amount of pH regulator, and adjusting the viscosity of the mixture to ≥3.0 Pa·s with an appropriate amount of deionized water to obtain a topcoat;

[0054] The weight percentage content of each component is: 30% to 65% of water-based acrylic r...

Embodiment 1

[0056] a) Weigh 160kg of deionized water, 5kg of Tego740W dispersant from Degussa, 30kg of carbon black, 80kg of 800 mesh mica powder, 100kg of ultrafine barium sulfate, 12kg of AMP-95pH regulator from Dow Chemical Company and Degussa Sai fumed silica 8kg, mix and stir evenly, the speed is 1500 rpm, and then grind to fineness ≤ 40μm;

[0057] b) Weigh 550kg of HD2535 water-based acrylic resin from Huajinsi, 5kg of Degussa’s Tego825 defoamer, 3kg of Degussa’s KL245 substrate wetting agent, and 10kg of Raybo 75 flash corrosion inhibitor from U.S. Ruibao 1, Tinuvin 5050 ultraviolet absorber 20kg of Tinuvin 5050 ultraviolet absorber 20kg of the film-forming aid dodecyl alcohol ester of Eastman company and Ciba company add in the mixture that last step obtains and stir, and the rotating speed is 1200 revs / min;

[0058] c) filtering the mixture obtained in b) to remove impurities;

[0059] d) adjusting the pH of the mixture to 8.3, and adjusting the viscosity of the mixture to 3.4 ...

Embodiment 2

[0061] a) Take by weighing 120kg of deionized water, 20kg of BYK110 dispersant of German BYK chemical company, 30kg of carbon black, 50kg of 800 mesh mica powder, 80kg of silicon micropowder, 30kg of pH regulator triethanolamine and 70kg of hydrogenated castor oil, mix and stir evenly, The rotating speed is 1600 rpm, and then grind to a fineness of ≤40μm;

[0062] b) Weigh 450kg of water-based acrylic resin from Huafeile Water-based Coatings Co., Ltd., 30kg of HX-2013 defoamer from Guangzhou Huaxia Auxiliary Chemical Company, 30kg of SNW 311 substrate wetting agent from Guangdong Luochi Trading Co., Ltd., SER- Add AD FA379 Elements flash corrosion inhibitor 40kg, Qingzhou Beite Chemical Co., Ltd.’s film-forming aid 20kg and Shijiazhuang Shijiao Chemical Co., Ltd.’s hindered amine light stabilizer 944 into the mixture obtained in the previous step and stir at a speed of 1100 rpm;

[0063] c) filtering the mixture obtained in b) to remove impurities;

[0064] d) adjusting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com