Loaded reduced precious metal catalyst as well as preparation method and application thereof

A noble metal catalyst and supported technology, which is applied in the field of supported reduced noble metal catalyst and its preparation, can solve the problems of complex catalyst preparation process, and achieve the effects of low energy consumption, mild reaction conditions and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

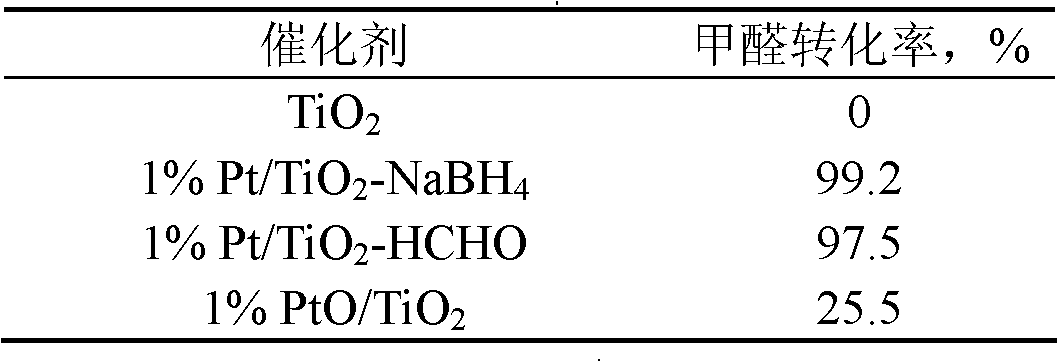

[0029] A kind of supported reduced noble metal catalyst, with TiO 2 It is a carrier, and its active component is the reduced noble metal platinum, and its content accounts for 1% of the total weight of the catalyst. It is prepared by the following method:

[0030] TiO2-supported noble metal catalysts with 1% platinum prepared by different reduction methods.

[0031] Preparation of 1%Pt / TiO by Reduction of Sodium Borohydride 2 Catalyst (identified as 1%Pt / TiO 2 -NaBH 4 ) is as follows: Weigh 2.5g of titanium dioxide, add 10ml of deionized water and stir continuously, add 12.82ml of 0.01mol / L chloroplatinic acid aqueous solution dropwise, stir for 1h, and adjust the pH value of the suspension to 8. At room temperature, 5 ml of aqueous solution containing 25 mg of sodium borohydride was added, and stirred for 1 h. Place in a water bath with constant stirring, and heat at 80°C to remove moisture from the solution. After drying in an oven at 80°C for 2h, continue heating at 1...

Embodiment 2

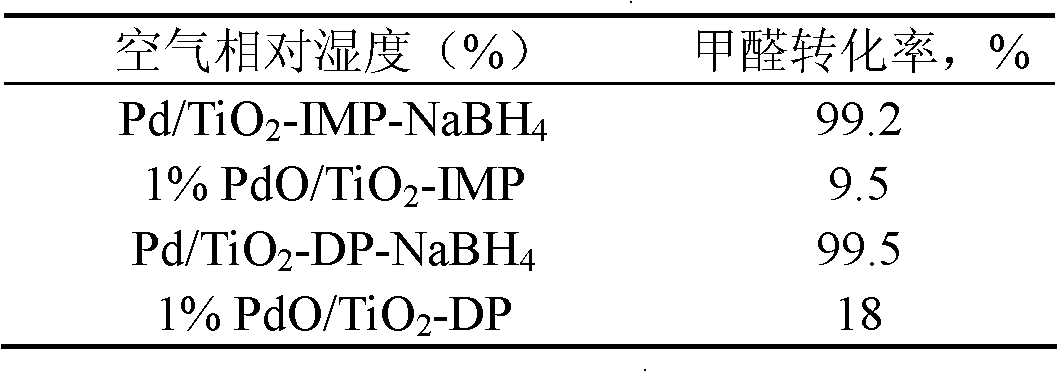

[0038] A kind of supported reduced noble metal catalyst, with TiO 2 It is a carrier, and its active component is palladium, a noble metal in reduced state, and its content accounts for 1% of the total weight of the catalyst. It is prepared by the following method:

[0039] Noble metal catalysts with 1% palladium supported on titania prepared by different methods.

[0040] Preparation of 1%Pd / TiO by impregnation-sodium borohydride reduction 2 Catalyst (identified as 1%Pd / TiO 2 -IMP-NaBH 4 ) is as follows: Weigh 2 g of titanium dioxide, add 10 ml of deionized water and stir continuously, add 8.4 ml of 0.0242 mol / L palladium chloride aqueous solution dropwise, and stir for 1 h. At room temperature, 5 ml of aqueous solution containing 25 mg of sodium borohydride was added, and stirred for 1 h. Place in a water bath with constant stirring, and heat at 80°C to remove moisture from the solution. After drying in an oven at 80°C for 2h, continue heating at 120°C for 4h to obtain ...

Embodiment 3

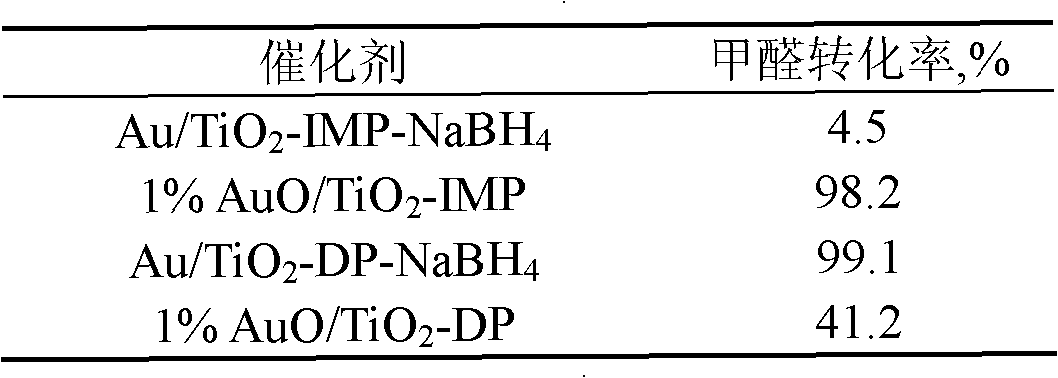

[0048] A kind of supported reduced noble metal catalyst, with TiO 2 It is a carrier, and its active component is reduced noble metal gold, and its content accounts for 1% of the total weight of the catalyst. It is prepared by the following method:

[0049] TiO2-supported noble metal catalysts with 1% gold prepared by different methods.

[0050] Preparation of 1% Au / TiO by Impregnation-NaBH Reduction Method 2 Catalyst (identified as 1% Au / TiO 2 -IMP-NaBH 4 ) is as follows: Weigh 2 g of titanium dioxide, add 10 ml of deionized water and stir continuously, add 10.1 ml of 0.01 mol / L aqueous chloroauric acid solution dropwise, and stir for 1 h. Add 5ml of aqueous solution containing 30mg of sodium borohydride at room temperature, and stir for 1h. Place in a water bath with constant stirring, and heat at 80°C to remove moisture from the solution. After drying in an oven at 80°C for 2h, continue heating at 120°C for 4h to obtain 1% Au / TiO 2 -IMP-NaBH 4 catalyst.

[0051] 1%A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com