Process for preparing polysaccharide of abalones

A technique for the preparation of abalone polysaccharides, which is applied in the field of polysaccharide extraction from shellfish, can solve problems such as environmental pollution, and achieve the effects of reducing environmental pollution, reducing pollution, and shortening the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The preparation process of the abalone polysaccharide of the present invention is mainly divided into four steps of raw material treatment, extraction, purification and alcohol precipitation. Specific steps are as follows:

[0014] A) Raw material processing: at room temperature or low temperature of 0-30°C, wash the fresh abalone meat or viscera, remove connective tissue, add distilled water according to the weight ratio of material to liquid 1:1-1:5, beat, and pass 20- 40-mesh sieve, stir evenly, and prepare abalone pretreatment liquid.

[0015] B) Extraction (any one of the following four methods can be used):

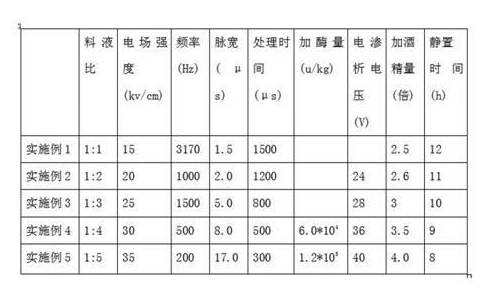

[0016] ①At normal temperature or low temperature, the abalone pretreatment liquid is treated by a high-voltage pulse electric field with an electric field strength of 15-35kV / cm, a frequency of 200-3170Hz, and a pulse width of 1.5μs-17μs, and the treatment time is 300-1500μs. Get the PEF treatment solution. C) Step: centrifuge at 10000-20000g, remove the p...

Embodiment 1

[0023] At 10°C, take 10kg of abalone meat or viscera that has been cleaned and removed of connective tissue, add distilled water at a material-to-liquid ratio of 1:1, beat, pass through a 40-mesh sieve, and stir well to prepare an abalone pretreatment solution. Treat the abalone pretreatment solution with a high-voltage pulse electric field, the electric field strength is 15kV / cm, the frequency is 3170Hz, the pulse width is 1.5μs, and the treatment time is 1500μs to obtain the PEF treatment solution, which is centrifuged under the condition of a separation factor of 15160G to remove the precipitate and take the supernatant liquid. Concentrate the obtained supernatant to a soluble solid content of 6%, add alcohol with a purity of more than 95% according to 2.5 times the volume of the feed liquid, and let it stand for 12 hours for alcohol precipitation. After alcohol precipitation, carry out sedimentation and centrifugation, and take the precipitate, which is abalone polysacchar...

Embodiment 2

[0025] At 20°C, take 10kg of abalone meat or viscera that has been cleaned and removed of connective tissue, add distilled water at a material-to-liquid ratio of 1:2, beat, pass through a 40-mesh sieve, and stir well to prepare an abalone pretreatment solution. The abalone pretreatment solution was treated by a high-voltage pulsed electric field with an electric field intensity of 20 kV / cm, a frequency of 1000 Hz, a pulse width of 2.0 μs, and a treatment time of 1200 μs to obtain a PEF treatment solution. Centrifuge under the condition that the separation factor is 15160G, remove the precipitate, and take the supernatant. A membrane stack of 40 membrane pairs is used, and the supernatant is subjected to electrodialysis treatment with a voltage of 24V to obtain the light phase. Concentrate the light-phase treatment liquid until the soluble solids content reaches 6%, add alcohol with a purity of 85% or more according to 2.6 times the volume of the feed liquid, and let it stand f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com