Method for synthesizing vanadium acid zinc micro/nanowire material by adopting hydrothermal method

A technology of nanowires and zinc vanadate, applied to the growth of polycrystalline materials, chemical instruments and methods, vanadium compounds, etc., to achieve the effect of simple operation and controllable experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

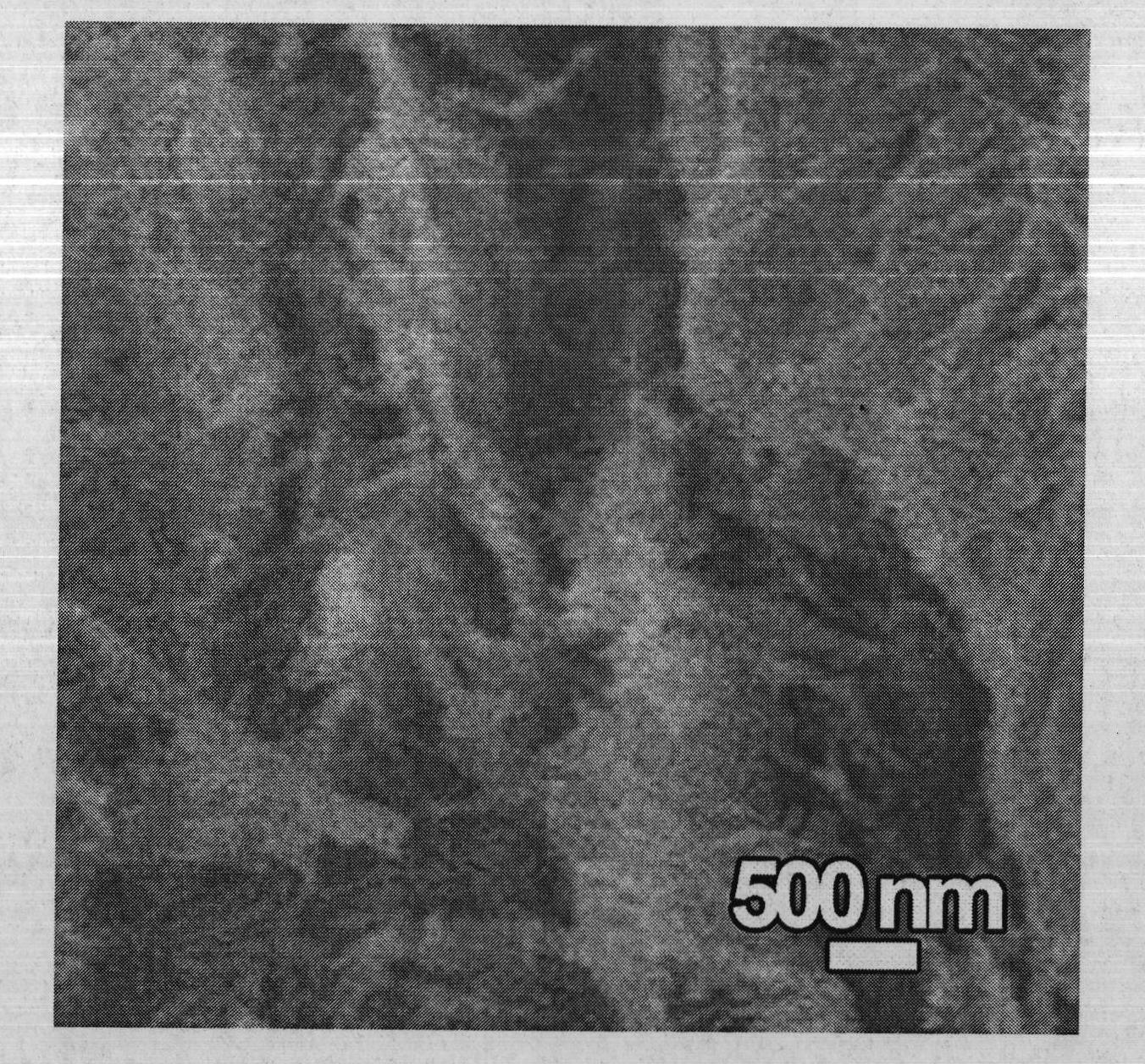

[0024] At room temperature, prepare a 0.00125 mol / L zinc nitrate aqueous solution, weigh the molar number of ammonium metavanadate solid to twice the molar number of zinc nitrate, add distilled water at 60-75°C until the ammonium metavanadate is completely dissolved, and then gradually Add it dropwise to an aqueous solution of zinc nitrate, move the mixed solution to a hydrothermal reaction kettle, and keep it in a 140-degree thermostat for 12 hours to prepare a pure-phase zinc vanadate micro / nano material. The product was scanned by SEM ( figure 1 ) shows that the product is an ultra-long nanowire with a uniform diameter, its diameter is 80-120 nanometers, the length can reach 3-10 microns, and the surface is smooth. Many nanowires are interwoven into a network structure, and there is a slight agglomeration phenomenon.

Embodiment 2

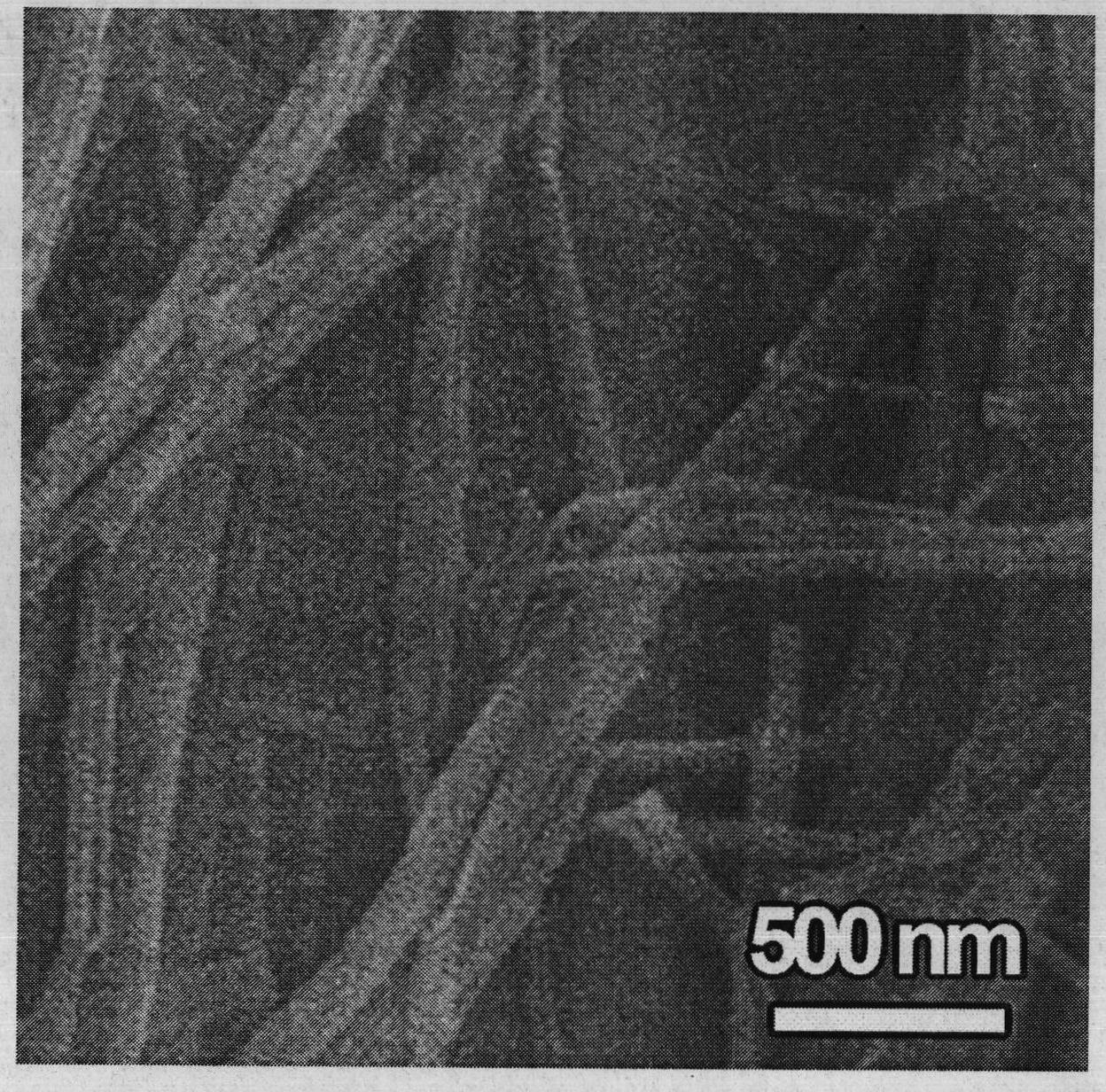

[0026] At room temperature, configure a 0.00750 mol / L zinc nitrate aqueous solution, weigh the molar number of ammonium metavanadate solid to twice the molar number of zinc nitrate, add distilled water at 60-75°C until the ammonium metavanadate is completely dissolved, and then gradually Add it dropwise to an aqueous solution of zinc nitrate, move the mixed solution to a hydrothermal reaction kettle, and keep it in a 140-degree thermostat for 12 hours to prepare a pure-phase zinc vanadate micro / nano material. The product was scanned by SEM ( figure 2 ) shows that the product is a nanowire with uniform length and diameter, its diameter is only 20-100 nanometers, and its length can reach 1-10 microns.

Embodiment 3

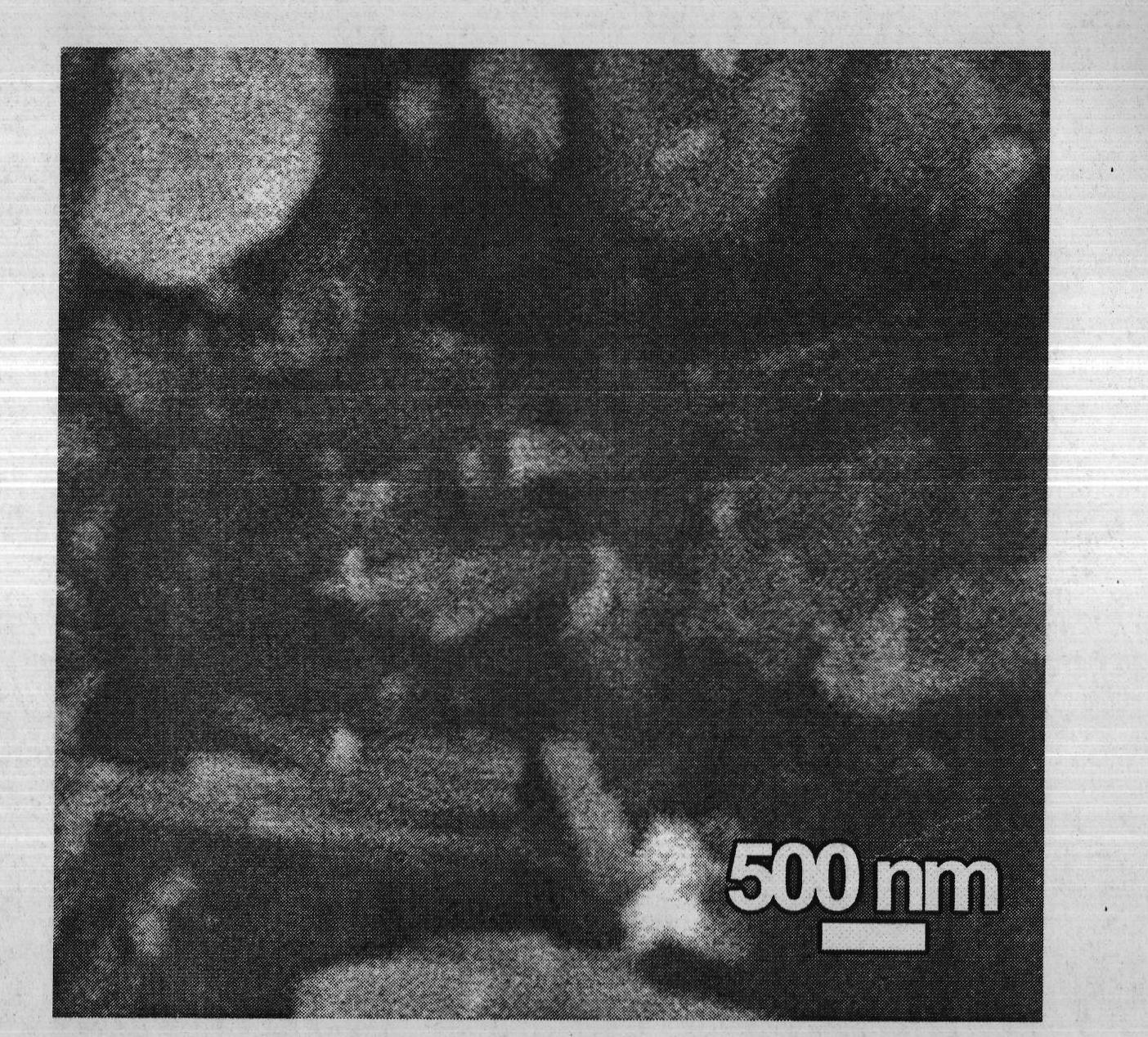

[0028] At room temperature, configure a 0.00875 mol / L zinc nitrate aqueous solution, weigh the molar number of ammonium metavanadate solid to twice the molar number of zinc nitrate, add distilled water at 60-75°C until the ammonium metavanadate is completely dissolved, and then gradually Add it dropwise to an aqueous solution of zinc nitrate, move the mixed solution to a hydrothermal reaction kettle, and keep it in a 140-degree thermostat for 12 hours to prepare a pure-phase zinc vanadate micro / nano material. The product was scanned by SEM ( image 3 ) shows that the product is a relatively large number of nanowires and a small amount of nanosheets; wherein, the well-dispersed nanowires have a uniform diameter and length, with a diameter of 50-100 nanometers and a length of 2-4 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com