Mulberry leaf extract with anti-corrosion function and application of mulberry leaf extract

A mulberry leaf extract and function technology, applied in the field of natural preservatives, can solve the problems of incomplete extraction of mulberry leaf effective components and high extraction cost, and achieve the effects of easy industrial production, reduced solvent use cost, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

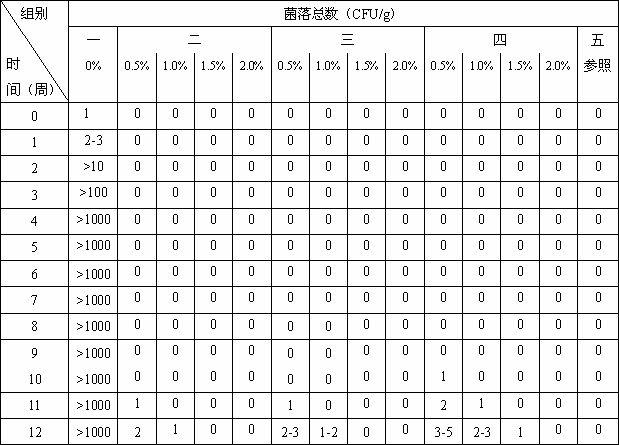

Image

Examples

Embodiment 1

[0028] (1) Put 500g of mulberry leaves in a water tank, add 12.5L of water, heat to 95°C for 2 hours, and filter out the extract; add 7.5L of water to the residue, extract for 2 hours under the same conditions, and remove the residue , combined two extracts;

[0029] (2) Concentrate to 1L under reduced pressure in a water bath at 55°C; add ethanol to make the final concentration of ethanol in the system 60%-70%, stir and mix thoroughly, let stand overnight and filter, concentrate the clear liquid to dryness, and obtain a crude extract after drying 77.7 g.

[0030] (3) Disperse the extract with 100-200mL of water and extract it with petroleum ether liquid-liquid, each time with 50mL of petroleum ether, extract 2-4 times until colorless, combine the upper layer of petroleum ether clear liquid, recover the solvent, and concentrate The product was vacuum-dried to obtain 0.315 g of product I as a pale yellow oil. Add chloroform to the remaining aqueous solution in the previous st...

Embodiment 2

[0032] (1) Weigh 500g of mulberry leaves, put them in a water tank, add 10L of water to submerge the mulberry leaves, heat to 85°C and extract twice, each time for 3 hours, the water demand for the second extraction can be appropriately reduced depending on the situation. It is advisable to immerse the mulberry leaves; combine the two extracts.

[0033] (2) Concentrate under reduced pressure to about 800mL, add ethanol for precipitation, so that the final concentration of ethanol in the system is 60% to 70%, and concentrate the filtrate to about 1000mL.

[0034] (3) Divide the concentrated solution into two parts on average, each concentrated solution is about 500mL, and one part is directly extracted with chloroform, each time with 125-250mL of chloroform for 2-4 extractions, extracted until colorless and then combined The solvent was recovered from the extract phase, and 0.6037 g of the extract product II was obtained after drying;

[0035] Another 500mL concentrated soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com