Method for preparing lysozyme molecular imprinting nano particles with magnetic responsiveness and extremely high adsorption capacity

A magnetic nanoparticle and molecular imprinting technology, applied in biochemical equipment and methods, chemical instruments and methods, enzymes, etc., can solve the problems of few adsorption sites, large biological protein molecules, and low selectivity of western blotting, etc. Simple, high physical and chemical stability, avoiding cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

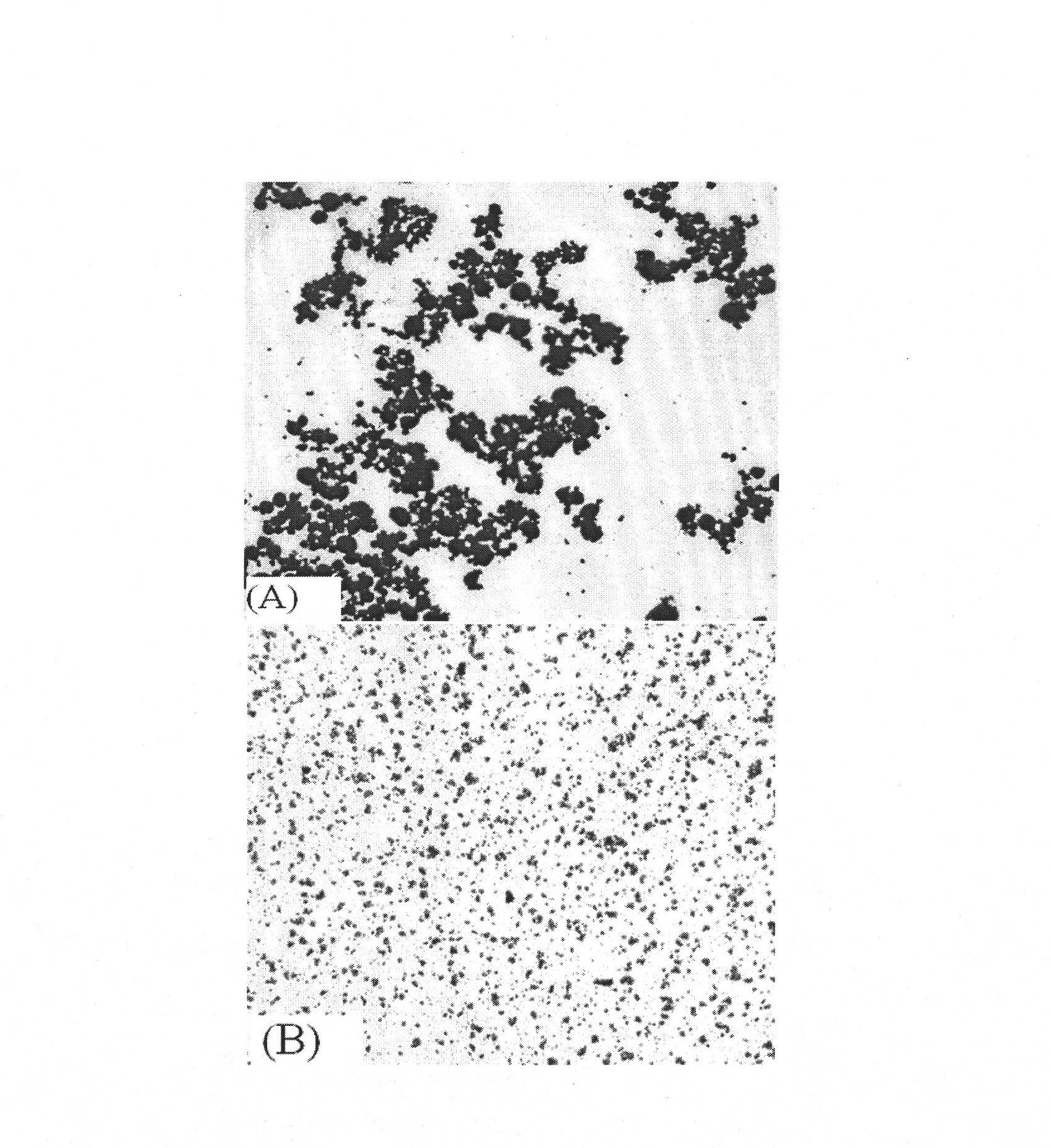

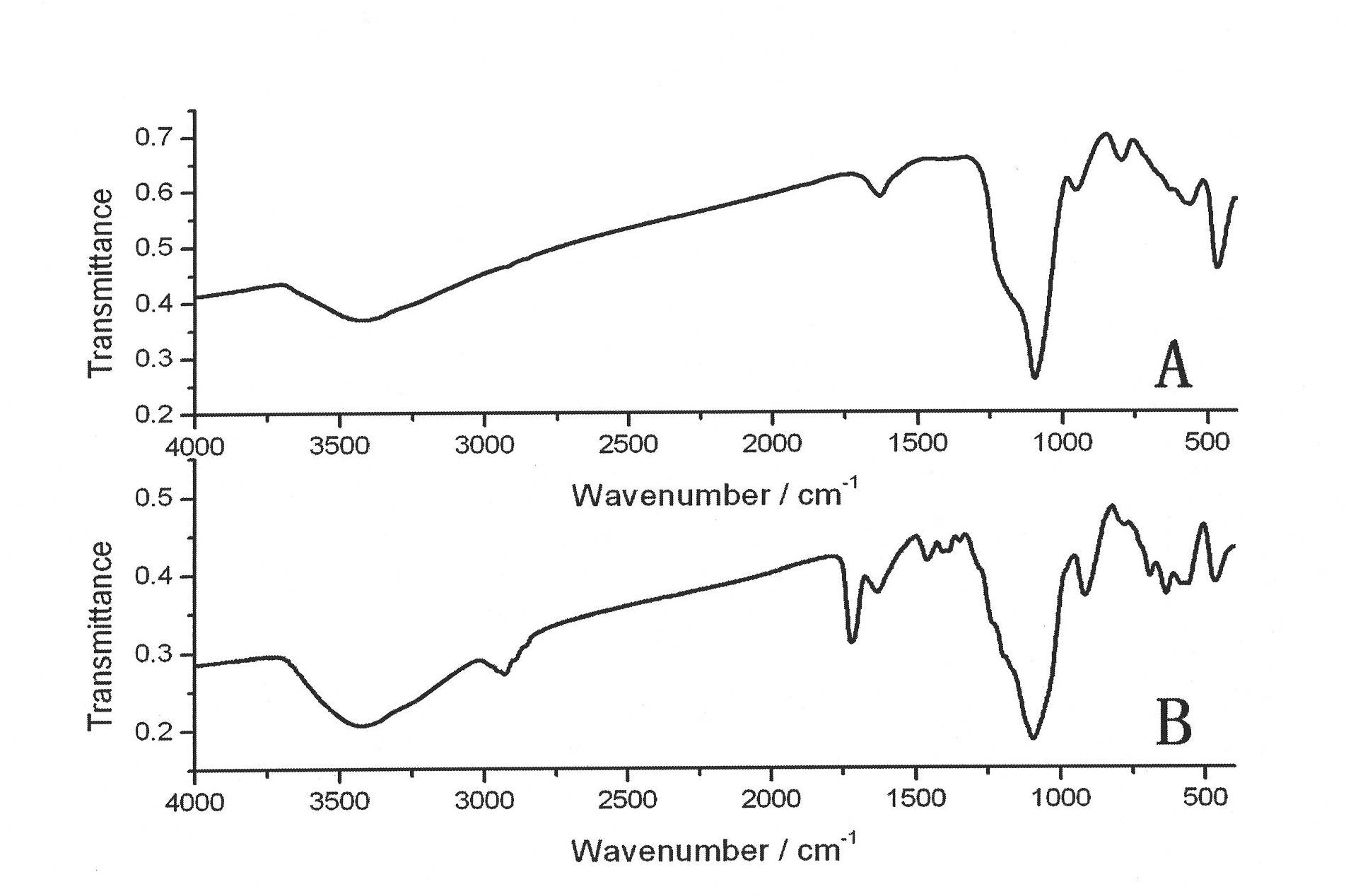

[0049] 1g magnetic material nano-Fe 3 o 4 Mix well with 100mL of 0.7mol / L sodium citrate, react at 40°C for 12 hours, then wash with pure water several times, and then disperse into ethanol solution. Next, add 0.5g of dispersed magnetic fluid, 0.5g of ammonia water and 0.6g of tetraethoxysilane into a mixed solution of 50mL of ethanol and water (5 / 1, V / V), and react for 12 hours at 40°C , coated with SiO on its surface 2 film. Subsequently, disperse 0.05mL of γ-mercaptopropyltrimethoxysilane and 0.05mL of methacryloxypropyltrimethoxysilane into 10mL of pure water, and after reacting for 5 hours, slowly add 200mg of coated SiO 2 thin film Fe 3 o 4 10 mL of pure water, reacted at 60°C for 12 hours, then washed with pure water several times, and dried in vacuum to form a brown powder. Finally, 20 mg of the template molecule lysozyme and acrylamide were dissolved in 10 mL of 0.2 mol / L phosphate buffered saline (pH 5.0) at a molar ratio of 1000:1, sonicated for 10 min, and th...

Embodiment 2

[0051] 15g magnetic material nano-Fe 3 o 4 Mix well with 300mL 0.8mol / L sodium citrate, react at 40°C for 12 hours, then wash with pure water several times, and then disperse into ethanol solution. Next, 5g of dispersed magnetic fluid, 5g of ammonia water and 6g of tetraethoxysilane were added to a mixed solution of 100mL of ethanol and water (2 / 1, V / V), and reacted for 12 hours at 40°C. Surface coated SiO 2film. Subsequently, disperse 0.14mL of γ-mercaptopropyltrimethoxysilane and 0.14mL of methacryloxypropyltrimethoxysilane into 20mL of pure water, and after 5 hours of reaction, slowly drop into the solution containing 600mg of coated SiO 2 thin film Fe 3 o 4 20 mL of pure water in 60°C for 12 hours, then washed several times with pure water and dried in vacuum to form a brown powder. Finally, 40 mg of the template molecule lysozyme and acrylamide were dissolved in 10 mL of 0.4 mol / L phosphate buffered saline (pH 6.0) at a molar ratio of 2000:1, sonicated for 7 minutes...

Embodiment 3

[0053] 50g magnetic material nano-Fe 3 o 4 Mix well with 500mL of 1mol / L oleic acid, react at 40°C for 24 hours, then wash with pure water several times, and then disperse into ethanol solution. Next, 20g of dispersed magnetic fluid, 40g of ammonia water and 12g of tetraethoxysilane were added to a mixed solution of 200mL of ethanol and water (5 / 1, V / V), and reacted for 24 hours at 60°C. Surface coated SiO 2 film. Subsequently, disperse 0.5mL of γ-mercaptopropyltrimethoxysilane and 0.5mL of methacryloxypropyltrimethoxysilane into 50mL of pure water, and after reacting for 10 hours, slowly drop into 2 thin film Fe 3 o 4 50 mL of pure water in 100°C, reacted for 24 hours, then washed with pure water several times, and dried in vacuum to form a brown powder. Finally, 120 mg of the template molecule lysozyme and acrylamide were dissolved in 20 mL of 0.5 mol / L phosphate buffered saline solution (pH 7.0) at a molar ratio of 3000:1, sonicated for 10 min, and then 300 mg of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com