Application of membrane bioreactor based on stainless steel fine filtering device in sewage treatment

A membrane bioreactor, sewage treatment technology, applied in biological water/sewage treatment, sustainable biological treatment, water/sewage multi-stage treatment, etc., can solve the problems of high investment cost, high maintenance cost and high operating energy consumption, Achieve the effect of low investment cost, low maintenance cost and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

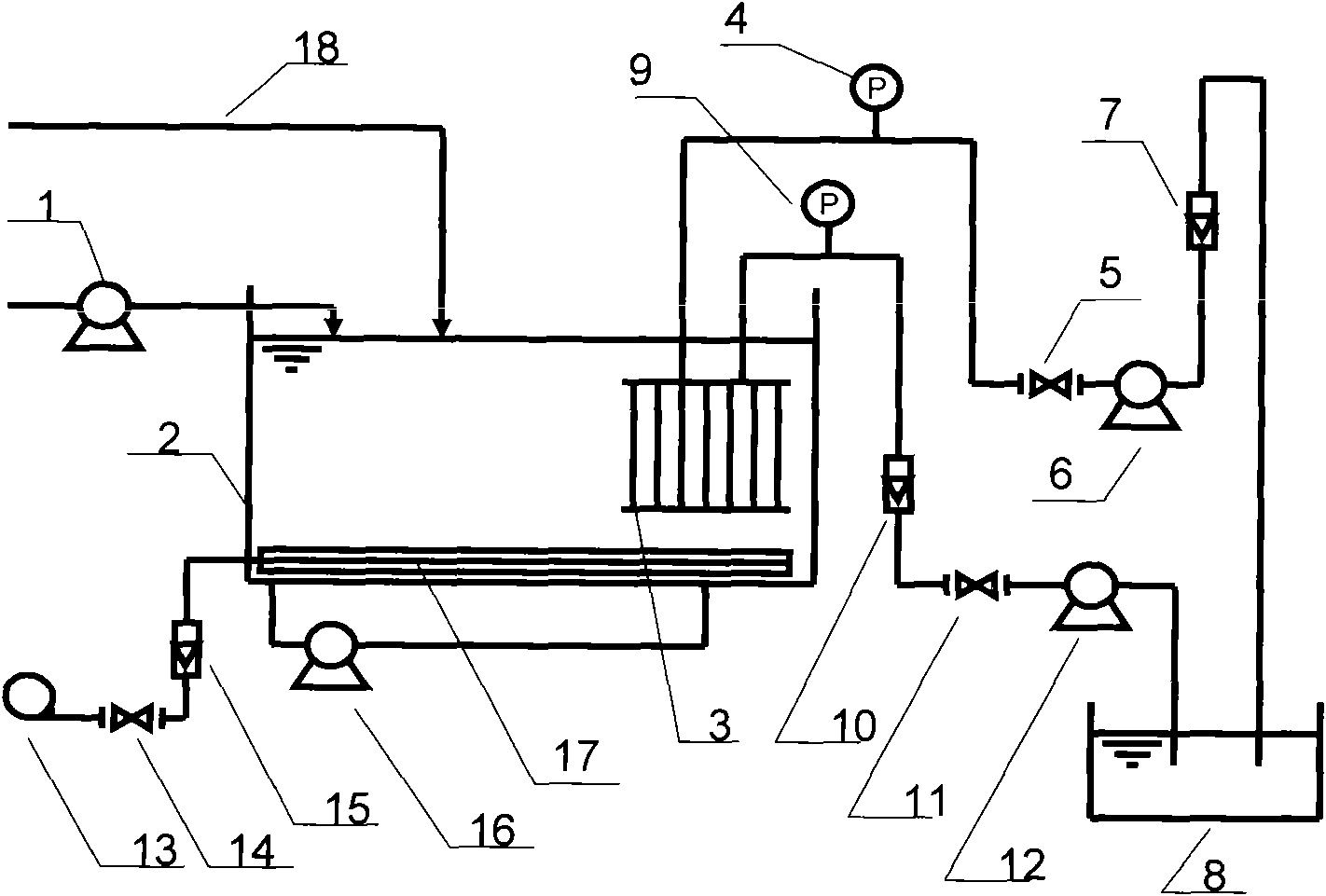

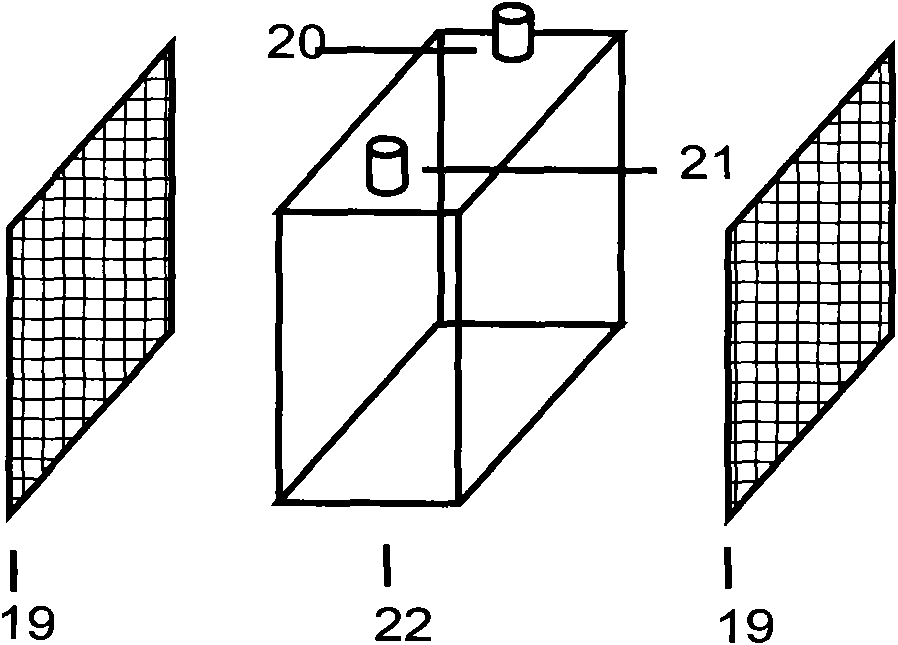

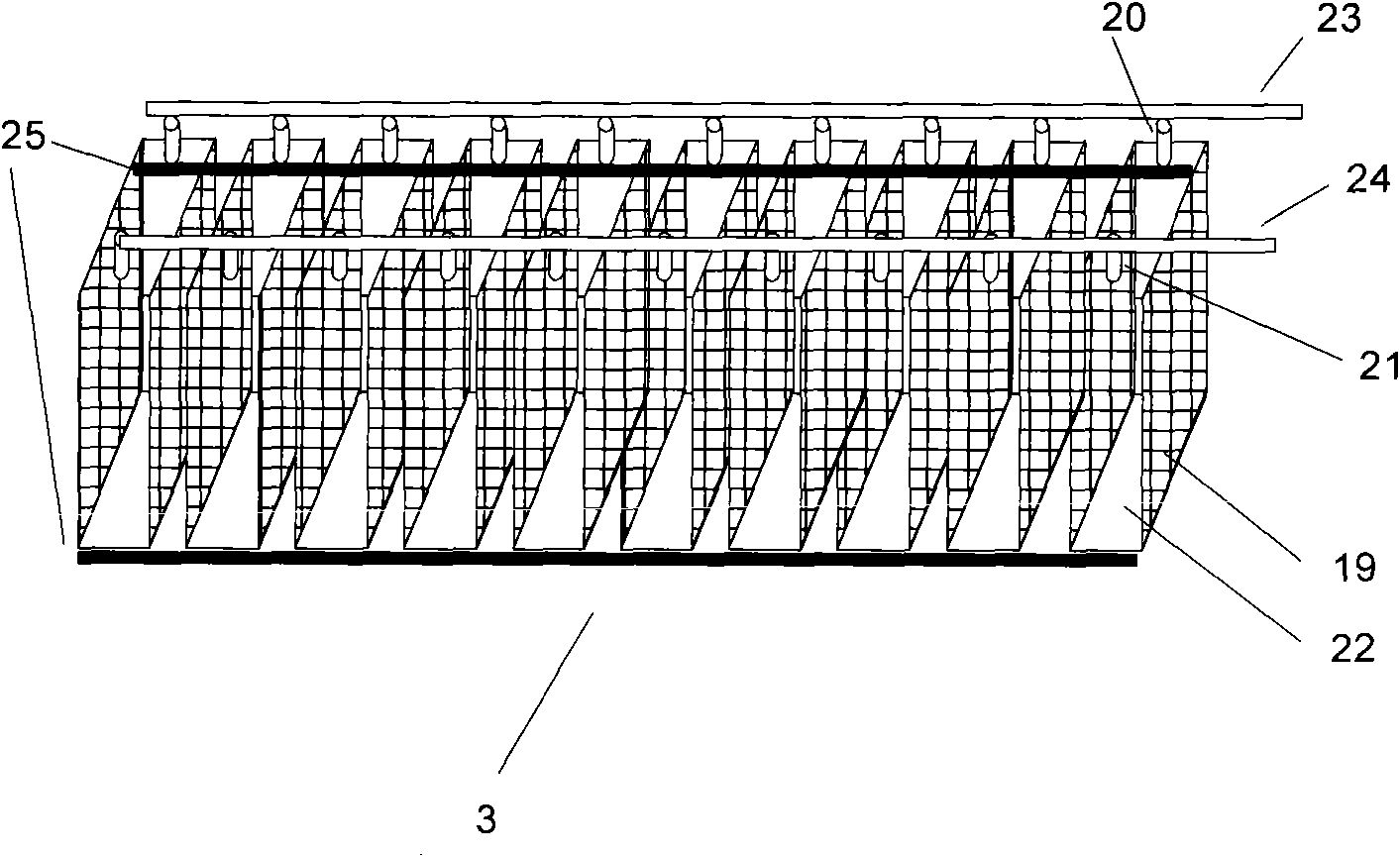

[0031] figure 1 A membrane bioreactor with a stainless steel wire mesh fine filtration module is shown.

[0032] After coarse filtration and initial sedimentation, the sewage is pumped into bioreactor 2. The liquid level of the sewage is monitored by the liquid level gauge 18, and the signal is transmitted to the PLC control cabinet to control the opening and closing of the sewage pump and the inlet 1. The aeration system of biochemical pool is made up of fan 13, air valve 14, air flow meter 15 and aerator 17. The flow of air is adjusted by PLC controlling the air valve 14 . The stainless steel wire mesh fine filter assembly 3 is connected to the water outlet system. The outlet system consists of outlet pressure gauge 4, outlet valve 5, outlet pump 6 and outlet flow meter 7. The outlet water flowmeter transmits the signal to the PLC control system, and maintains a balanced outlet water (150-200L / m 2 h). The negative pressure of the outlet water is less than 0.02MPa. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com