Method for preparing titanium dioxide array film on flexible metallic matrix and application of method in lithium ion battery

A flexible metal and titanium dioxide technology, applied in alkaline battery electrodes, metal material coating process, coating, etc., can solve the problems of film substrate selection restrictions, achieve stable charge-discharge cycle performance, mild preparation conditions, and avoid corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

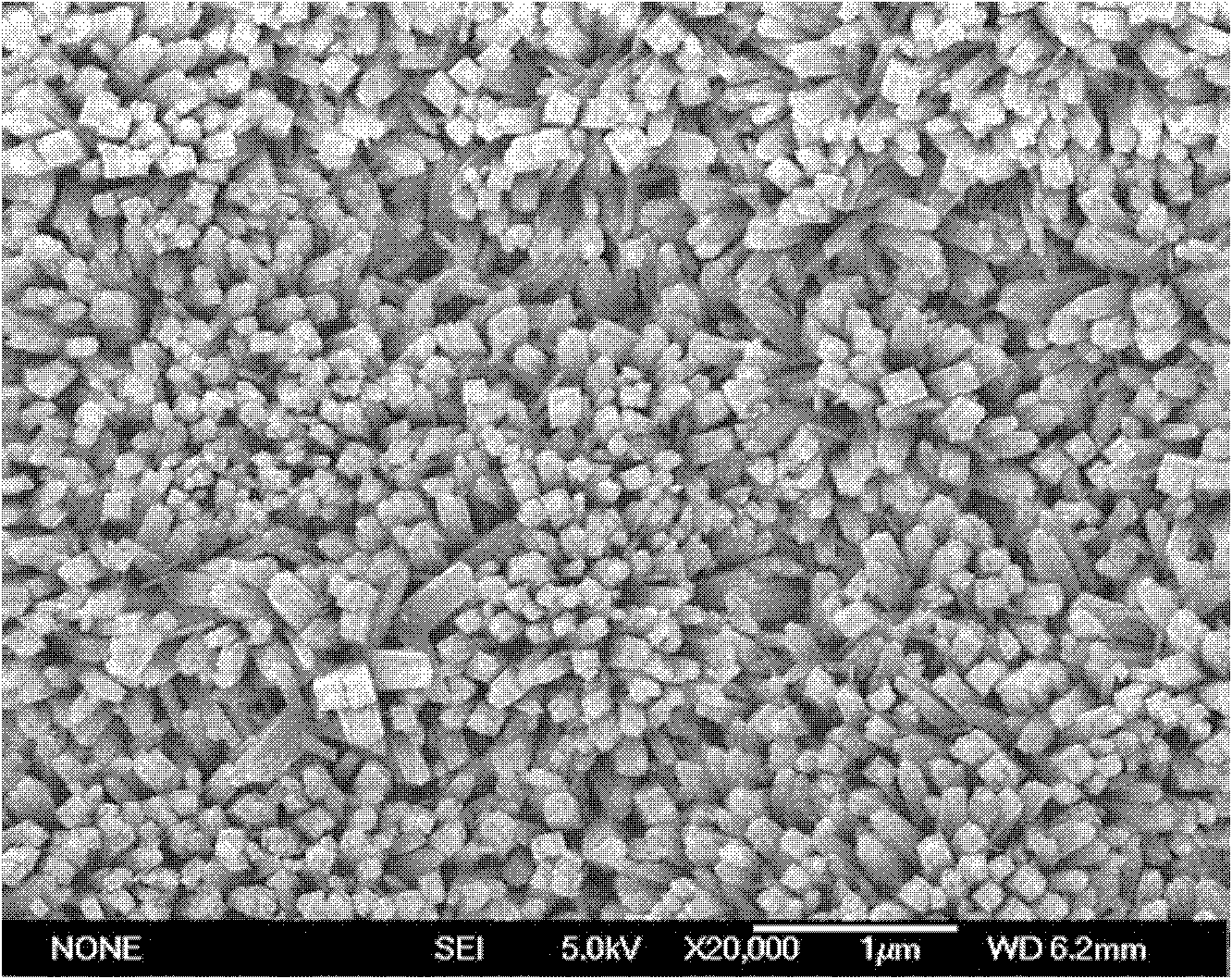

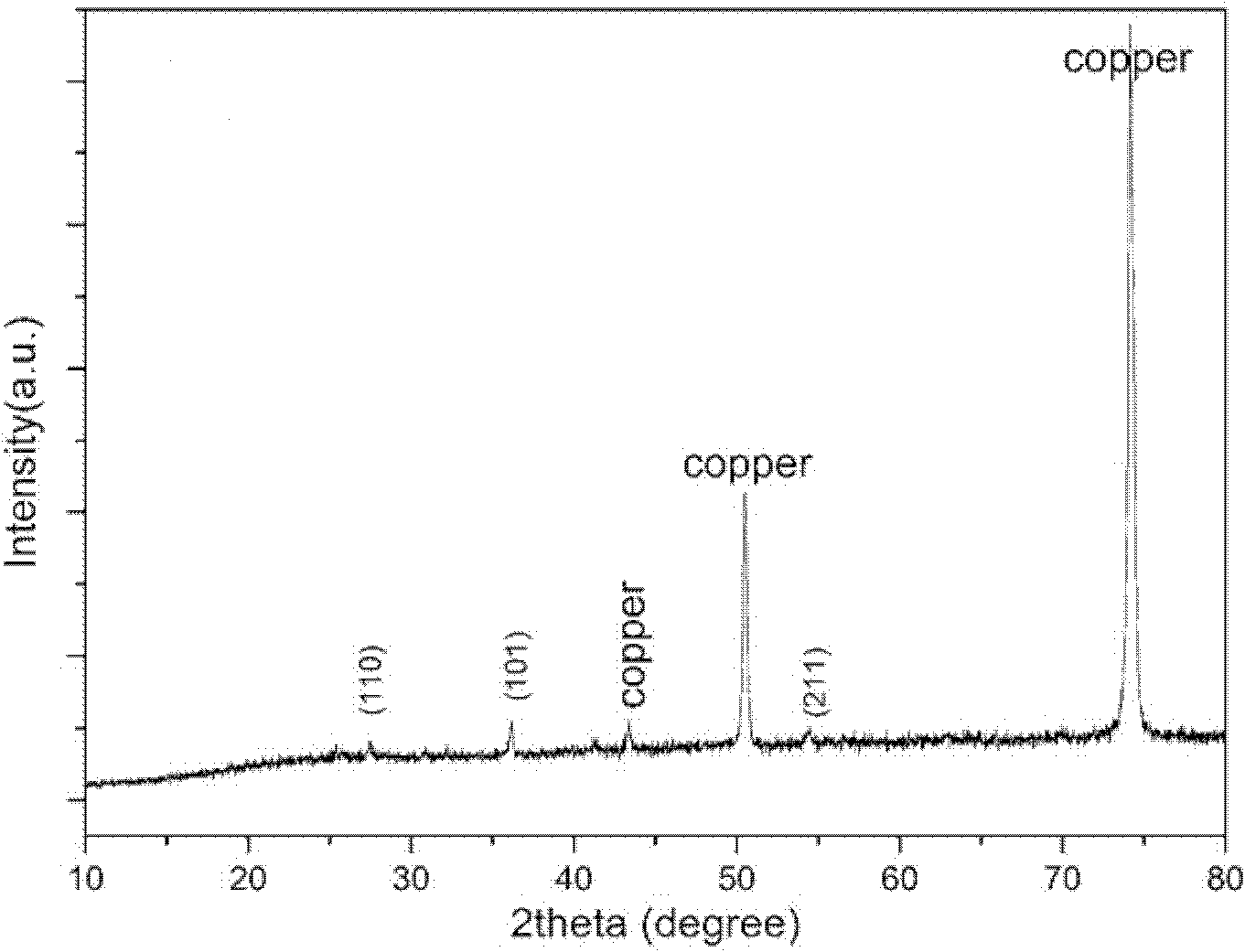

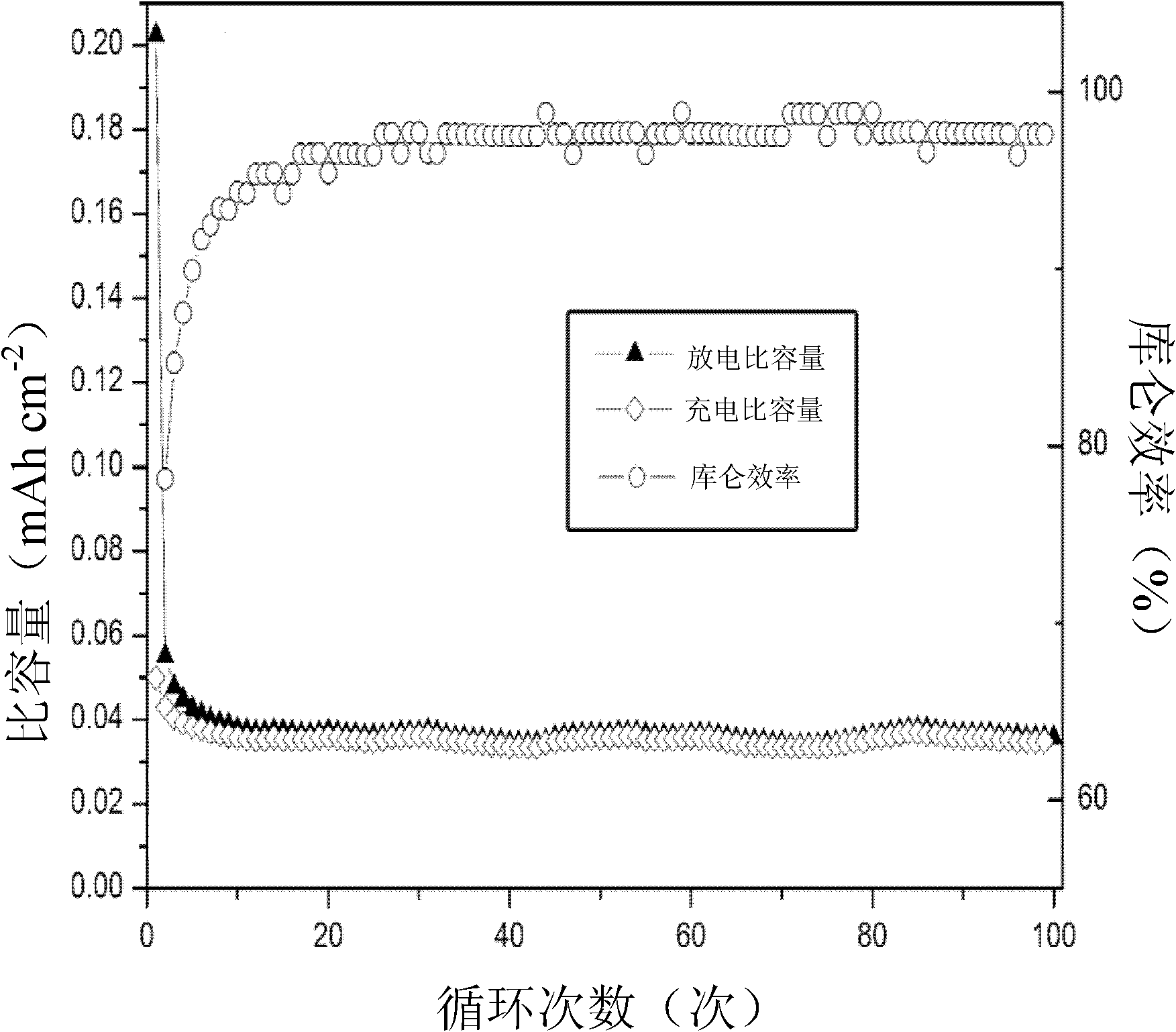

[0046] Embodiment 1 prepares titanium dioxide array film on copper foil

[0047] Step 1: Clean the copper foil

[0048] Dip copper foil into 0.5M sulfuric acid (H 2 SO4 ) in the washing solution for ultrasonic cleaning for 5 minutes, then immersed in acetone (C 3 h 6 (0) after ultrasonic cleaning for 10 min, take it out, rinse with deionized water to remove impurities on the surface of the substrate, and obtain a clean substrate;

[0049] Step 2: Prepare the first mixed solution

[0050] Titanium trichloride (or titanium tetrachloride (TiCl 4 )) is dissolved in saturated sodium chloride (NaCl) solution to form the first mixed solution;

[0051] Dosage: The molar concentration of titanium salt in the first mixed solution is 0.1M;

[0052] Step 3: Prepare the second mixture

[0053] Add urea ((NH 2 ) 2 CO) form the second mixed solution;

[0054] Dosage: The mass concentration of urea in the second mixed solution is 12g / L;

[0055] In the present invention, urea ((NH ...

Embodiment 2

[0063] Example 2 Preparation of titanium dioxide array film on titanium foil

[0064] Step 1: Clean the titanium foil

[0065] Dip the titanium foil into 0.5M sulfuric acid (H 2 SO 4 ) in the washing solution for ultrasonic cleaning for 10 minutes, then immersed in acetone (C 3 h 6 (0) after ultrasonic cleaning for 8 min, take it out, rinse with deionized water to remove impurities on the surface of the titanium foil, and obtain a clean titanium foil;

[0066] Step 2: Prepare the first mixed solution

[0067] Titanium oxysulfate (TiOSO 4 ) is dissolved in a saturated sodium chloride (NaCl) solution to form a first mixed solution;

[0068] Dosage: The molar concentration of titanium salt in the first mixed solution is 0.2M;

[0069] Step 3: Prepare the second mixture

[0070] Add urea ((NH 2 ) 2 CO) form the second mixed solution;

[0071] Dosage: The mass concentration of urea in the second mixed solution is 8g / L;

[0072] In the present invention, urea ((NH 2 ) ...

Embodiment 3

[0079] Example 3 Preparation of titanium dioxide array film on stainless steel sheet

[0080] Step 1: Clean the stainless steel sheet

[0081] Dip the stainless steel piece into 0.5M sulfuric acid (H 2 SO 4 ) ultrasonically cleaned in the lotion for 6 minutes, then immersed in acetone (C 3 h 6 (2) after ultrasonic cleaning for 15min, take it out, rinse with deionized water to remove impurities on the surface of the stainless steel sheet, and obtain a clean stainless steel sheet;

[0082] Stainless steel sheet size (length, width and thickness): 10cm×3cm×0.2cm

[0083] Step 2: Prepare the first mixed solution

[0084] Titanium sulfate (Ti(SO 4 ) 2 ) is dissolved in a saturated sodium chloride (NaCl) solution to form a first mixed solution;

[0085] Dosage: The molar concentration of titanium salt in the first mixed solution is 0.15M;

[0086] Step 3: Prepare the second mixture

[0087] Add urea ((NH 2 ) 2 CO) form the second mixed solution;

[0088] Dosage: The mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com