Fast-assembly lightweight steel combined house

A quick-installed, light-steel technology, applied in the direction of roof, roof covering, truss structure, etc., can solve the problems of monotonous style, bulky volume, and large amount of steel, achieving low cost, good seismic performance, and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: if figure 1 As shown, the embodiment of the present invention provides a method for making a quick-installed light steel structure composite building component:

[0031] 1) A: Guide rail production: according to the technical requirements, cut the required thin steel plate into a certain specification, and roll it into a U shape. After straightening and leveling, drill screw holes on it according to the drawing, and finally carry out anti-corrosion treatment and Packaging and storage.

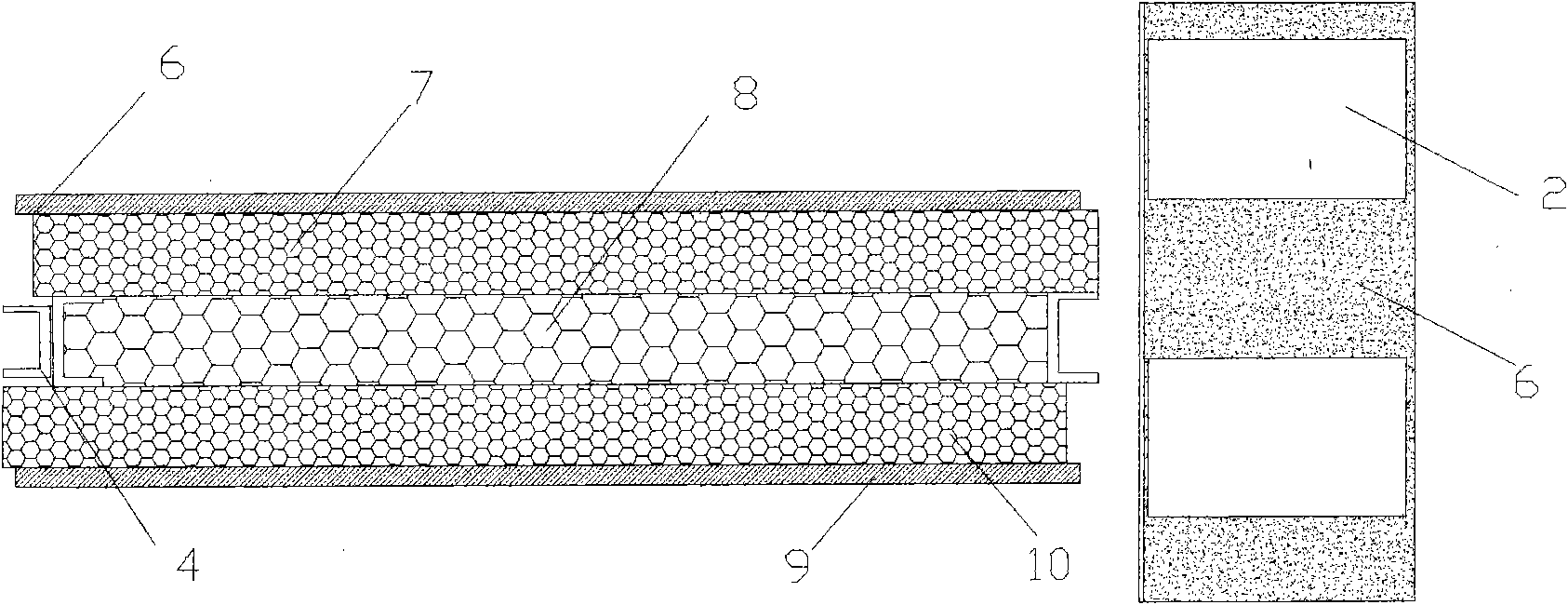

[0032] 2) B: Production of composite thermal insulation wall panels:

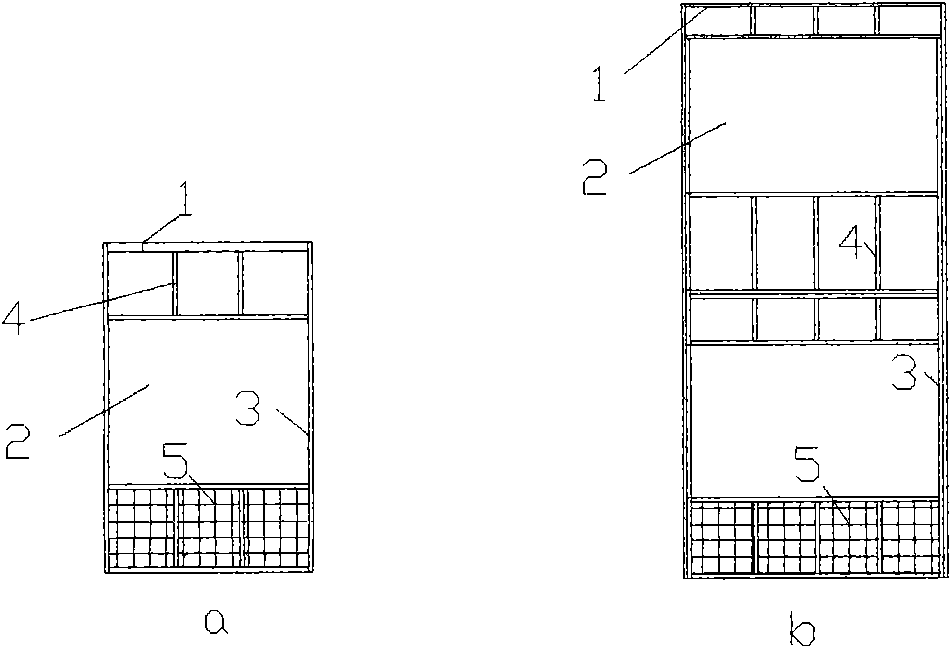

[0033] a: The production of light steel skeleton 3: such as figure 2 As shown, according to the technical requirements, the required thin steel plates are cut into certain specifications, and rolled into C-shaped; The light steel frame 4 is put into the mould, assembled, and welded and fixed with an electric welding machine, so that the light steel frame 3 is produced; after passing the inspection,...

Embodiment 2

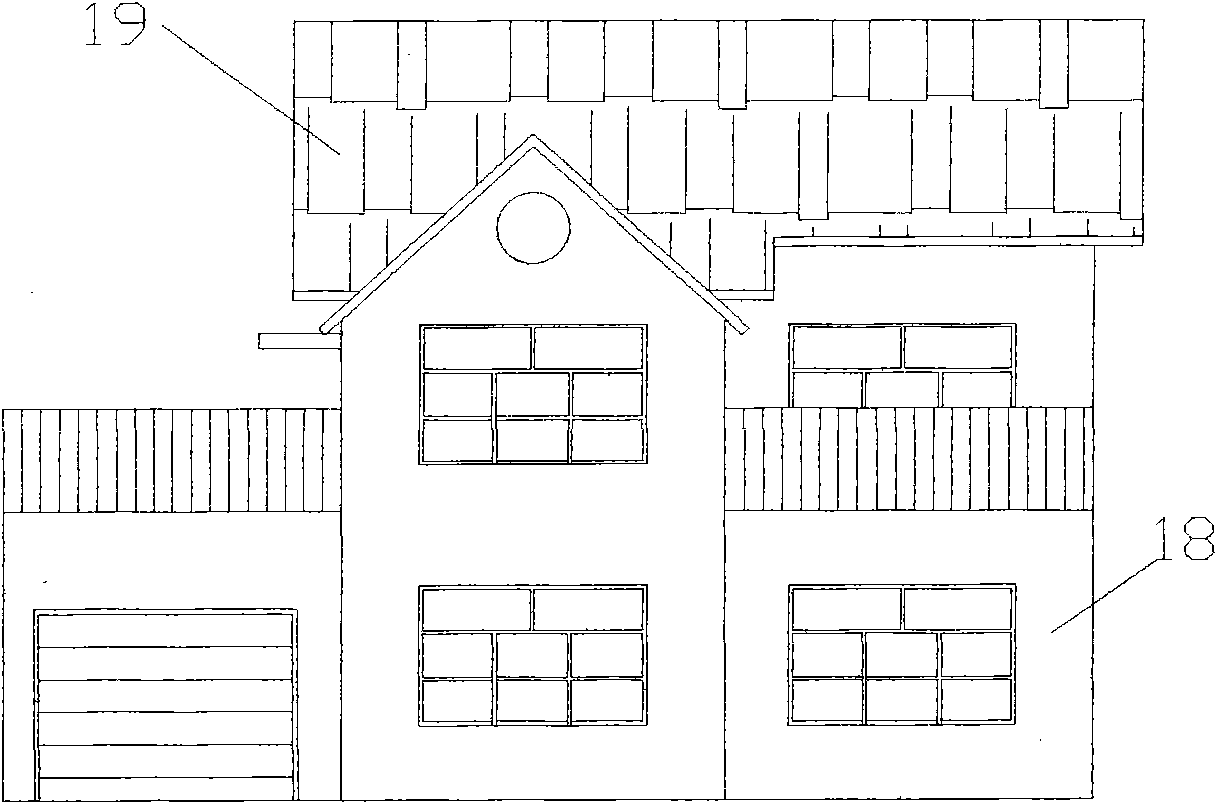

[0041] The embodiment of the present invention provides the construction and installation of a double-layer quick-installed light steel structure house:

[0042] First, carry out leveling and laying out on the foundation, and use anchor bolts to fix the guide rail on the foundation beam after leveling according to the drawing, and then install the wallboard:

[0043] like Figure 8 As shown, the No. 1 composite thermal insulation board (corner wall panel) is fixed to the guide rail with dovetail nails after being calibrated vertically; secondly, the No. 2 composite thermal Wallboard) fixed with dovetail nails; in this way, assemble the No. 22 board according to the number according to the figure, and then use Figure 9 Shown I-shaped connector 22 No. 1 composite thermal insulation wallboard 20 ( Figure 8 No. 1 board) is the same as No. 23 composite thermal insulation wall board 21 ( Figure 8 No. 23 board in the board) is fixed with dovetail nails, and the installation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com