Cystine-containing complex and its production method

A manufacturing method, technology of cystine, applied in pedicure system, food preparation, body powder, etc., can solve problems such as not found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0130] Hereinafter, the present invention will be described more concretely by way of examples. However, the present invention is not limited to these Examples. However, in the following examples and the like, % indicating the concentration of a solution or the like is weight % unless the unit is indicated otherwise.

[0131] I. Cystine-Collagen Peptide Complex

Embodiment I-1

[0133] For the cystine-collagen peptide complex, first, L-cystine was dissolved in a potassium carbonate solution having a pH of 10 or higher at 90°C to prepare a 2% cystine solution. This was returned to room temperature (25° C.), and a 50% aqueous solution of collagen peptide was slowly added thereto and stirred. As the collagen peptide solution used, a 50% aqueous solution (pH 4.6) of collagen peptide (manufactured by Nitta Gelatin Inc.) derived from porcine material with an average molecular weight of 3000 was prepared and added to the above-mentioned 2% cystine solution. At room temperature (25° C.), 32 g of a 50% aqueous solution of the collagen peptide (manufactured by Nitta Gelatin Inc.) was slowly mixed with 5 g of a 2% cystine solution and stirred, and when the pH was lowered to 9, cloudiness occurred. Thereafter, the reaction was continued at room temperature for 30 minutes, and after the completion of the reaction, 8 g of 1M phosphate buffer was added to adjust the...

Embodiment I-2

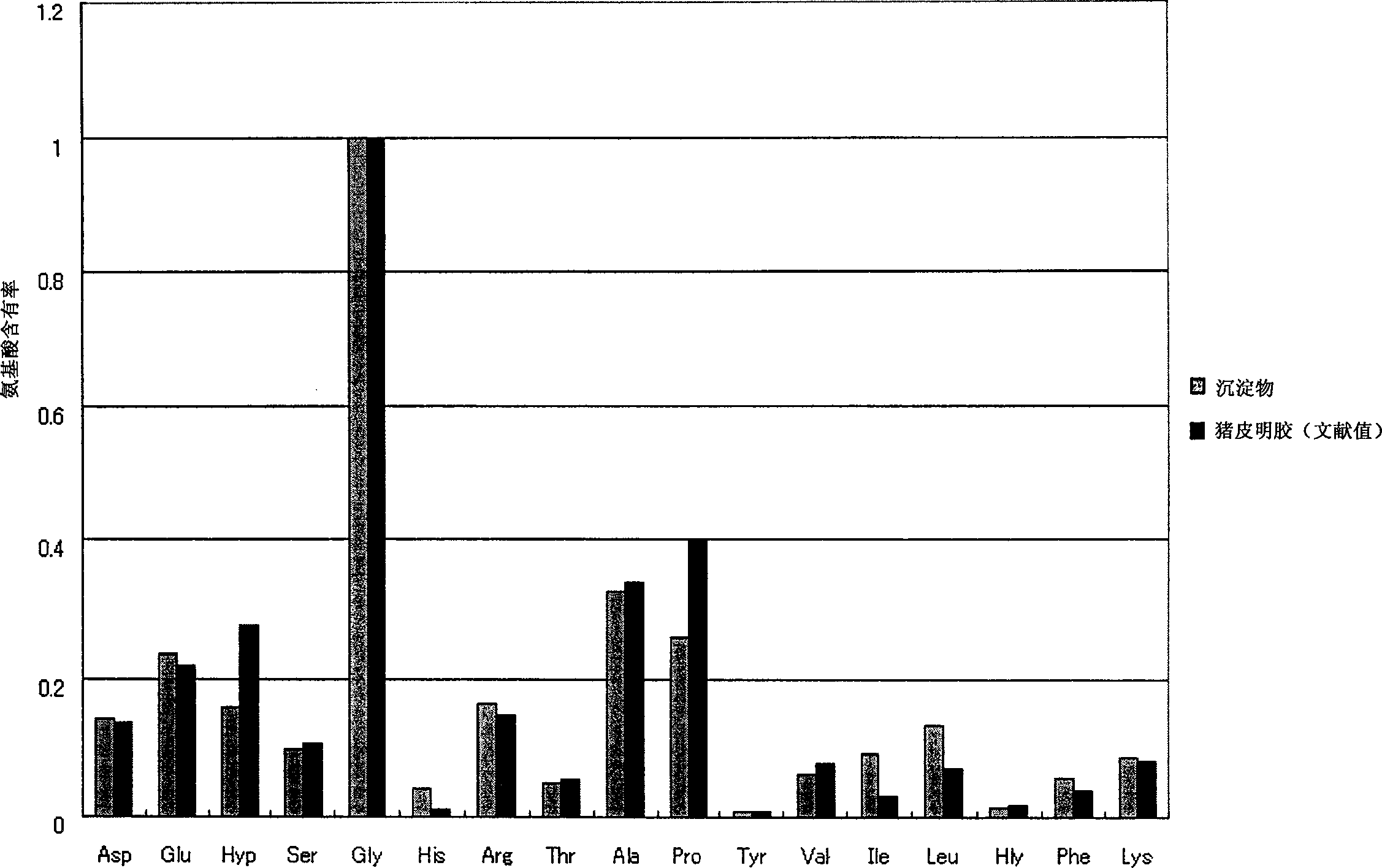

[0137] A part of the precipitate obtained in Example I-1 was put into a Durham tube, and after degassing according to the conventional method of "Pico Tag amino acid analysis method" which is one of the amino acid composition analysis methods, , acid hydrolysis treatment at 150°C for 1 hour. In addition, after derivatization into PTC amino acid (phenylthiocarbamoyl amino acid) using PITC (phenylisothiocyanate), it was separated by a dedicated HPLC reverse-phase chromatographic column for amino acid composition analysis. As a result, the total amount of cystine and cysteine was detected as cysteine (half cystine) (in amino acid analysis, the total content of cystine and cysteine) was 22.5 mol%. Furthermore, 18.2 mol% was detected as glycine, and 5.2 mol% was detected as proline. Take a part of the precipitate obtained from Comparative Example I-1 as a control, put it into a De Hahn test tube, degas, carry out acid hydrolysis at 150°C for 1 hour, and analyze the amino acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com