Amorphous silicon image sensor with storage capacitor structure

An image sensor and storage capacitor technology, applied in radiation control devices and other directions, can solve the problems of reducing the capacitance of photodiodes, reducing the effective area of photodiodes, and reducing the ability of photodiodes to store charges, so as to improve the dynamic range of signals and increase the charge storage capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The specific process steps in the first embodiment are as follows:

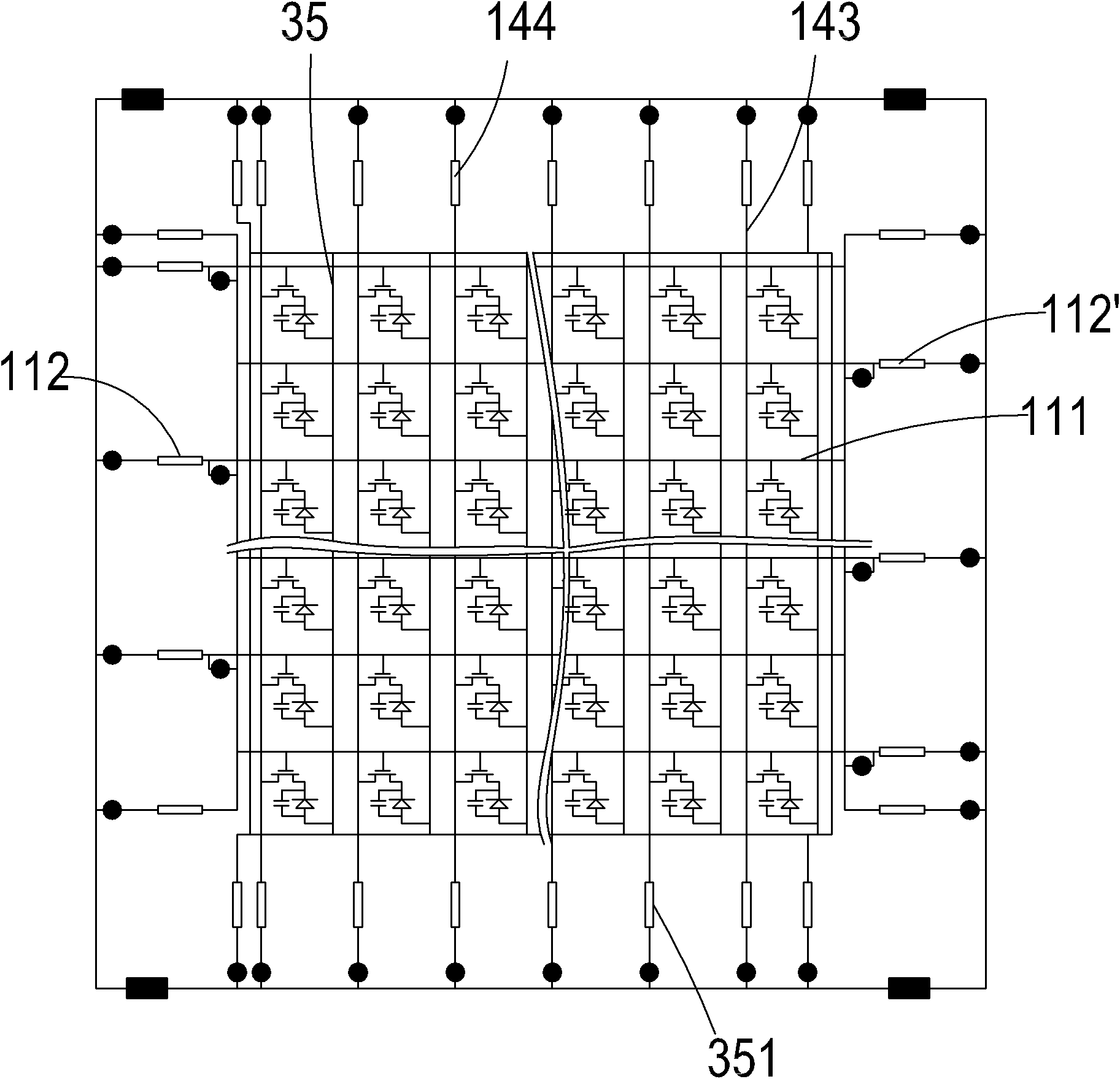

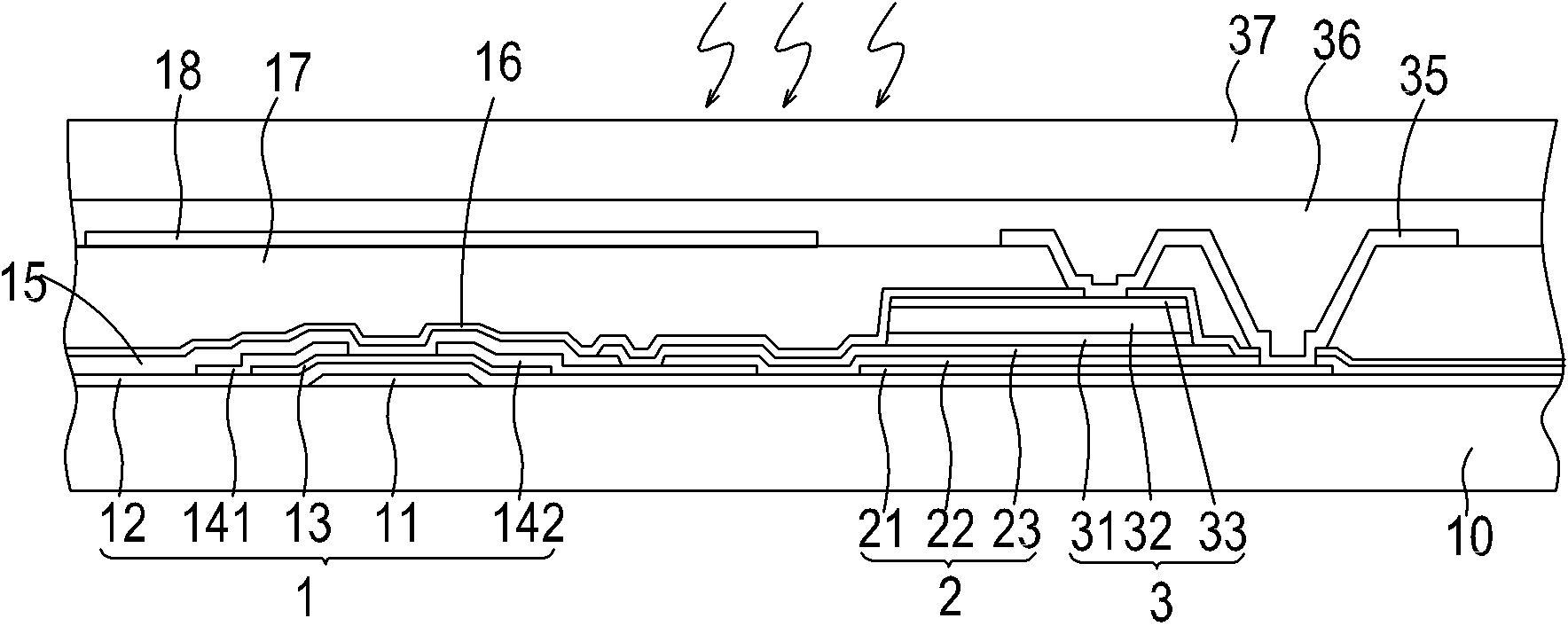

[0062] (1) As attached Image 6 And Figure 16 As shown, a first layer of metal is deposited on a glass substrate 10, and an etching process is used to form a gate electrode 11 and a gate line 111;

[0063] (2) As attached Figure 7 , 8 As shown in Figure 17, a first insulating layer 12 is formed on a glass substrate 10, an active layer 13 composed of an intrinsic amorphous silicon film and an n-type amorphous silicon film is formed, and the active layer 13 is etched to form a silicon island using a photolithography process ;

[0064] (3) Deposit the second layer of metal;

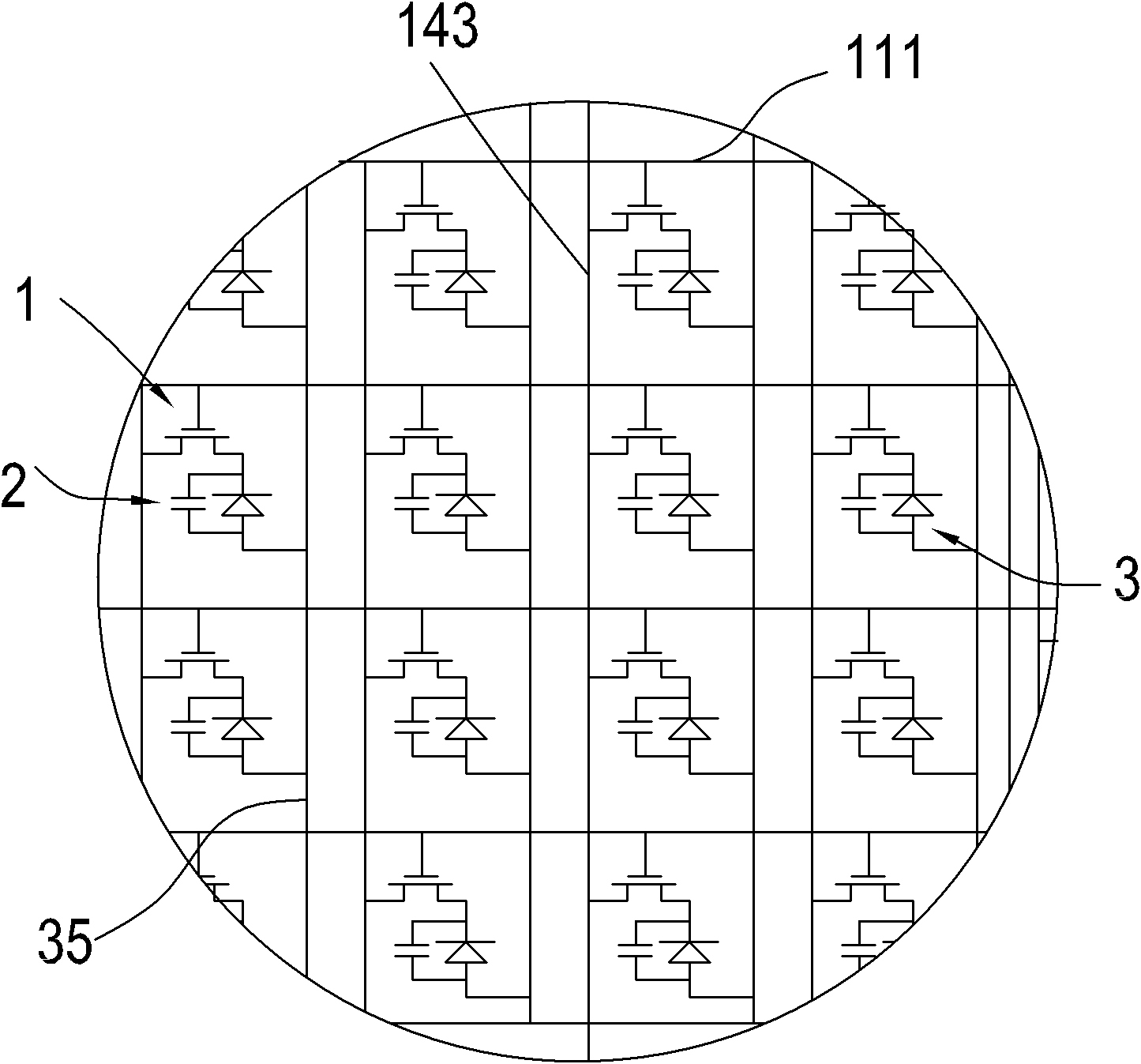

[0065] (4) As attached Picture 9 , 18 As shown, the data line 143, the drain electrode 141, the source electrode 142, and the lower electrode 21 of the storage capacitor are formed by an etching process. At this time, the thin film transistor 1 has been formed;

[0066] (5) Depositing the second insulating layer 15,

[0067] (6) See a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com