Electrochemical deposition preparation method for composite material used for microelectrode modification

A composite material and micro-electrode technology, applied in the direction of electrochemical variables of materials, material analysis by electromagnetic means, material analysis, etc., can solve the problems of non-conductivity, increase the AC impedance of PEDOT-GO, etc., and achieve excellent mechanical stability. and electrical conductivity, good biocompatibility, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Electrolyte preparation:

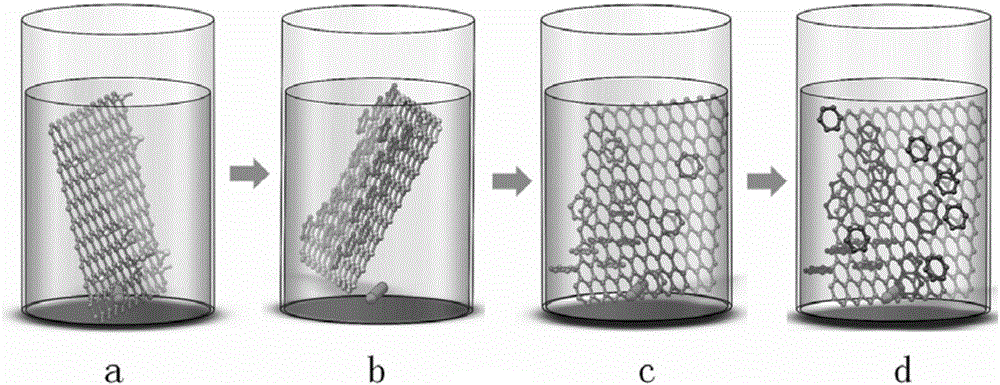

[0045] Measure 10 ml of 2 mg / ml GO aqueous solution (XFNANO) with a graduated cylinder, and then dilute it 20 times with deionized water to obtain 0.1 mg / ml GO aqueous solution. Use a graduated cylinder to measure 60ml of the diluted solution into a 100ml beaker and ultrasonically disperse it for 30min to obtain the following: figure 1 The graphene oxide aqueous solution shown in a.

[0046] Weigh 0.01g (1mM / L) ascorbic acid with micro balance and add to figure 1 The solution in a was then stirred until it was completely dissolved. Use a dropper to drop an appropriate amount of ammonia water into the solution so that the pH of the solution is between 9-10. Adjust the temperature of the oil bath heating pot to 95°C and keep the temperature constant for more than 10 minutes. Subsequently, the beaker was sealed with aluminum foil and placed in an oil bath for heating, the rotating speed of the magnetic stirrer was adjusted to 700rpm and timin...

Embodiment 2

[0054] Electrolyte preparation:

[0055] Measure the GO aqueous solution of 60ml 2mg / ml into the beaker of 100ml with graduated cylinder and ultrasonically disperse 30min to obtain such as figure 1 The graphene oxide aqueous solution shown in a.

[0056] Weigh 0.2g (20mM / L) ascorbic acid with micro balance and add to figure 1 The solution in a was then stirred until it was completely dissolved. Use a dropper to drop an appropriate amount of ammonia water into the solution so that the pH of the solution is between 9-10. Adjust the temperature of the oil bath heating pot to 95°C and keep the temperature constant for more than 10 minutes. Subsequently, the beaker was sealed with aluminum foil and placed in an oil bath for heating, the rotating speed of the magnetic stirrer was adjusted to 700rpm and timing was started. After reacting for 20min, the beaker was taken out and cooled at room temperature to obtain the following figure 1 rGO aqueous solution shown in b.

[0057] ...

Embodiment 3

[0063] Electrolyte preparation:

[0064] Measure the GO aqueous solution of 60ml 2mg / ml into the beaker of 100ml with graduated cylinder and ultrasonically disperse 30min to obtain such as figure 1 The graphene oxide aqueous solution shown in a.

[0065] Weigh 1.2g (20mg / ml) ascorbic acid with micro balance and add to figure 1 The solution in a was then stirred until it was completely dissolved. Subsequently, the beaker was sealed with aluminum foil and stirred vigorously on a magnetic stirrer. After reacting at room temperature for 24 hours, the following figure 1 rGO aqueous solution shown in b.

[0066] Towards figure 1 Add 0.3g PSS (5mg / ml) to the rGO solution shown in b and stir to dissolve to obtain figure 1 The mixed solution shown in c.

[0067] with a pipette figure 1 Add 60 μL (0.01M / L) of EDOT monomer to the mixed solution shown in c, then stir for more than 2 hours until it is completely dissolved, and prepare the following figure 1 The mixed solution show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com