Platinum nano wire modified microelectrode array and preparation method thereof

A micro-electrode array, platinum nanowire technology, applied in the direction of electrodes, nanotechnology, head electrodes, etc., can solve the problems of insufficient surface roughness, falling off of the electrode surface, poor mechanical stability, etc., and achieve rapid surface roughness, The effect of increased surface area and strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a platinum nanowire-modified microelectrode array, comprising the following steps:

[0034] (1) At room temperature, add 1L of water and 1mmol of platinum chloride (PtCl 4 ) and 6mmol formic acid (HCOOH), shake and mix gently to form a chemical deposition solution;

[0035] (2) Place the microelectrode to be modified in the above-mentioned chemical deposition solution, store it at room temperature for 36 hours, put the microelectrode in water, and ultrasonicate for 30 minutes under the condition of power of 600W and frequency of 40KHz to remove the For platinum nanowires with poor adhesion to the electrode substrate, a layer of platinum nanowires with good biocompatibility, large surface area and good binding force is formed on the surface of the microelectrode, that is, a platinum nanowire-modified microelectrode array is obtained.

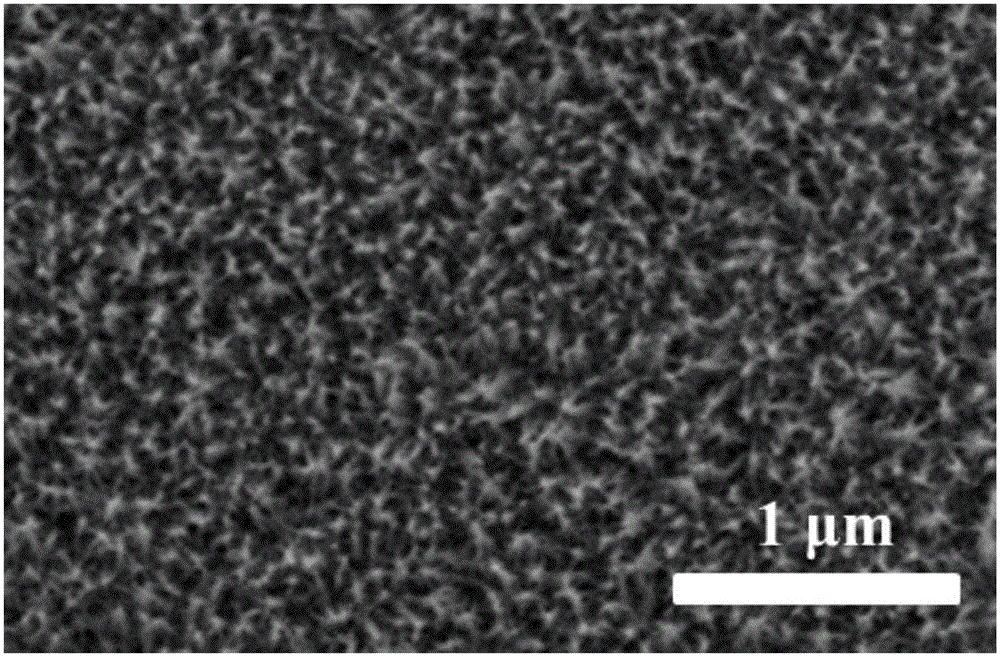

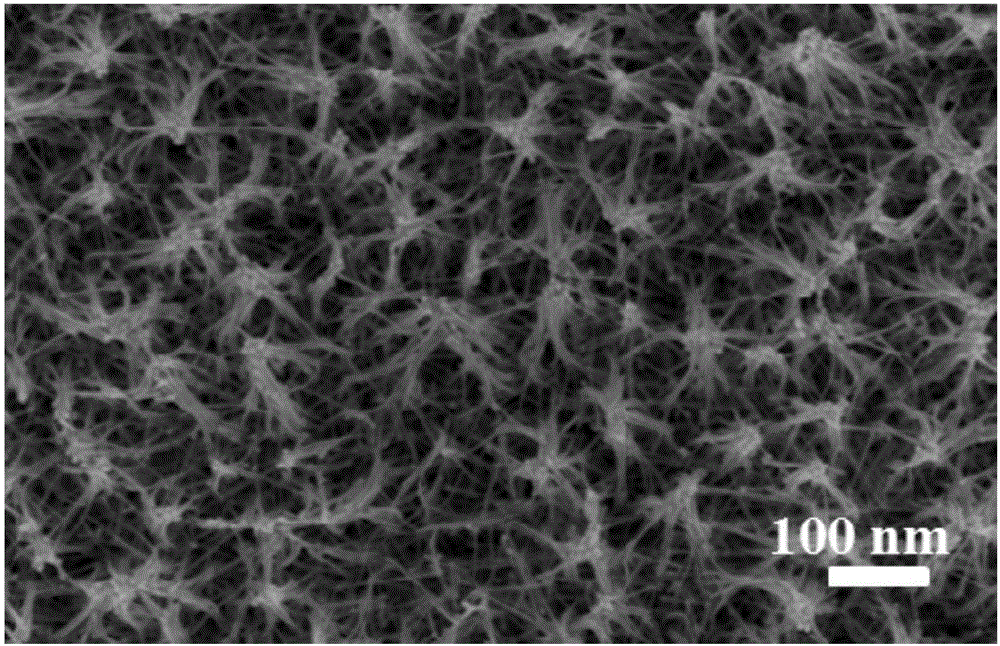

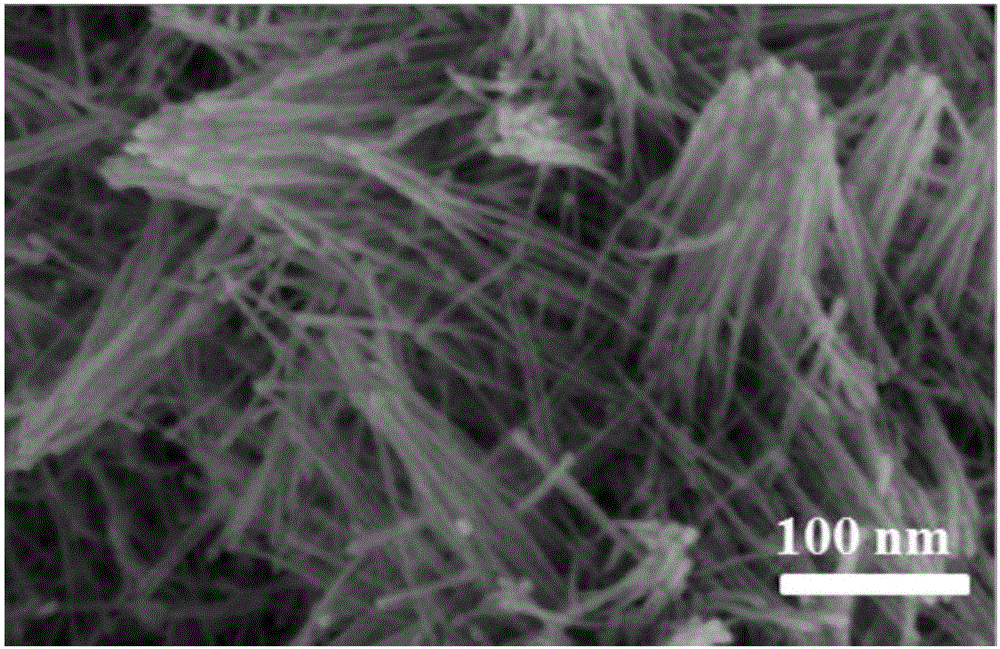

[0036] figure 1 , figure 2 as well as image 3 It is a scanning electron microscope (SEM) picture of the plat...

Embodiment 2

[0038] A method for preparing a platinum nanowire-modified microelectrode array, comprising the following steps:

[0039] (1) At room temperature, add 1L of water and 2mmol of platinum nitrate (Pt(NO 3 ) 4) and 8mmol formic acid (HCOOH), shake and mix gently to form a chemical deposition solution;

[0040] (2) Place the microelectrode to be modified in the above chemical deposition solution, store it in the dark at room temperature for 36 hours, place the microelectrode in water, and ultrasonicate for 50 minutes under the condition of power of 600W and frequency of 40KHz, Remove the platinum nanowires with poor adhesion to the electrode substrate, and a platinum nanowire modification layer with good biocompatibility, large surface area and good binding force is formed on the surface of the microelectrode, that is, a platinum nanowire modified microelectrode array is obtained. .

Embodiment 3

[0042] A method for preparing a platinum nanowire-modified microelectrode array, comprising the following steps:

[0043] (1) At room temperature, add 1L of water, 5mmol of ammonium hexachloroplatinate ((NH 4 ) 2 PtCl 6 ) and 10mmol sodium citrate (Na 3 C 6 h 5 o 7 ), shake gently to mix, chemical deposition solution;

[0044] (2) Place the microelectrode to be modified in the above-mentioned chemical deposition solution, store it at room temperature for 36 hours, put the microelectrode in water, and ultrasonicate it for 10 minutes under the condition of power of 600W and frequency of 40KHz to remove the For platinum nanowires with poor substrate adhesion, a platinum nanowire modification layer with good biocompatibility, large surface area and good binding force is formed on the surface of the microelectrode, that is, a platinum nanowire modified microelectrode array is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com