Coordination polymer material with multistage pore passage structure and preparation method thereof

A technology of coordination polymer and pore structure, which is applied in the direction of copper organic compounds, silver organic compounds, gold organic compounds, etc., can solve the problems of cost increase and achieve low cost, good application prospects, and large specific surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing a coordination polymer material with a multi-level pore structure, comprising the following steps:

[0025] 1) Dissolve the inorganic salt containing metal ions and the organic ligand in the solvent respectively, and then mix together to form a mixed solution, or directly dissolve the inorganic salt containing metal ions and the organic ligand together in the solvent to form a mixed solution, and stir evenly , wherein the ratio of the amount of the metal ion to the amount of the organic ligand is 0.2-5, wherein in order to obtain a mixed solution, it can be heated to aid dissolution or / and utilize ultrasonic waves to aid dissolution, and the heating temperature is not high in principle at the boiling point of the solvent;

[0026] 2) Put the mixed solution in the reaction kettle and let it stand at room temperature -180°C until the coordination polymer gel is obtained;

[0027] 3) Drying the coordination polymer gel to obtain a coordination polym...

Embodiment 1

[0057] 1) Dissolve 0.0016mol of chromium nitrate nonahydrate in 2ml of ethanol as reaction component A, weigh 0.0016mol of 1,3,5-benzenetricarboxylic acid and dissolve in 2ml of ethanol as reaction component B, Reaction component A and reaction component B are mixed together to form a mixed solution, stirred evenly, and placed in a 15ml reaction kettle;

[0058] 2) Put the mixed solution in an oven at 80°C and let it stand until the coordination polymer gel is obtained;

[0059] 3) Continue aging the coordination polymer gel in an oven at 80°C for 2 days;

[0060] 4) Wrap the coordination polymer gel with filter paper, put it into a Soxhlet extractor, heat and reflux with 200ml ethanol for Soxhlet extraction, and the extraction time is 12 hours;

[0061] 5) Put the coordination polymer gel wrapped in filter paper into a supercritical kettle and dry it with supercritical carbon dioxide. The drying time is 1 day to obtain a coordination polymer material with a multi-level pore ...

Embodiment 2

[0064] 1) Dissolve 0.0018mol of chromium nitrate nonahydrate and 0.0012mol of 1,3,5-benzenetricarboxylic acid in 3 ml of ethanol to form a mixed solution, stir well, and place in a 15ml reaction kettle;

[0065] 2) Put the mixed solution in an oven or drying oven at 80°C and let it stand until the coordination polymer gel is obtained;

[0066] 3) Continue aging the coordination polymer gel in an oven at 80°C for 2 days;

[0067] 4) Wrap the coordination polymer gel with filter paper, put it into a Soxhlet extractor, heat and reflux with 200ml ethanol for Soxhlet extraction, and the extraction time is 12 hours;

[0068] 5) After the extraction, put the coordination polymer gel wrapped in filter paper into a supercritical kettle for supercritical carbon dioxide drying. The drying time is 1 day to obtain a coordination polymer material with a multi-level pore structure.

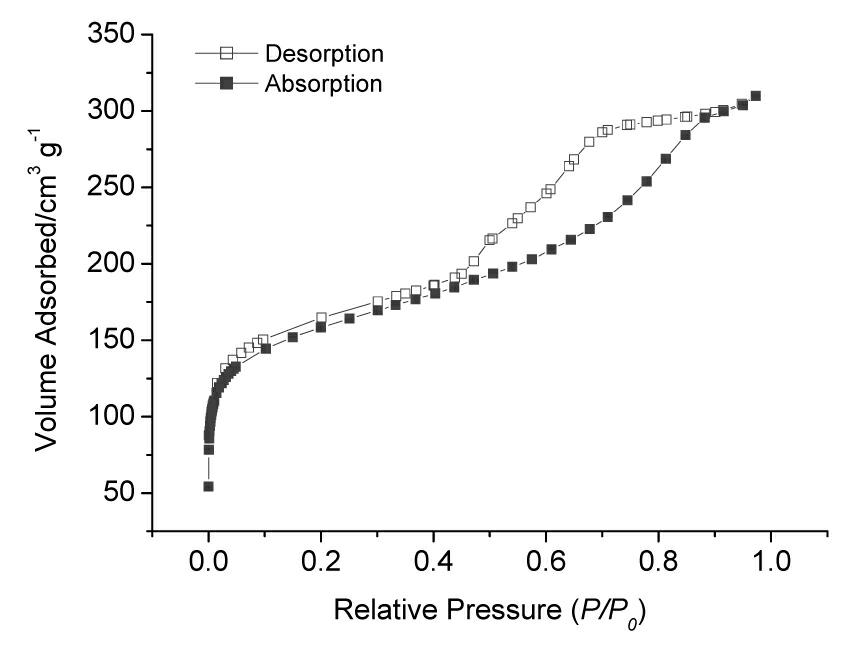

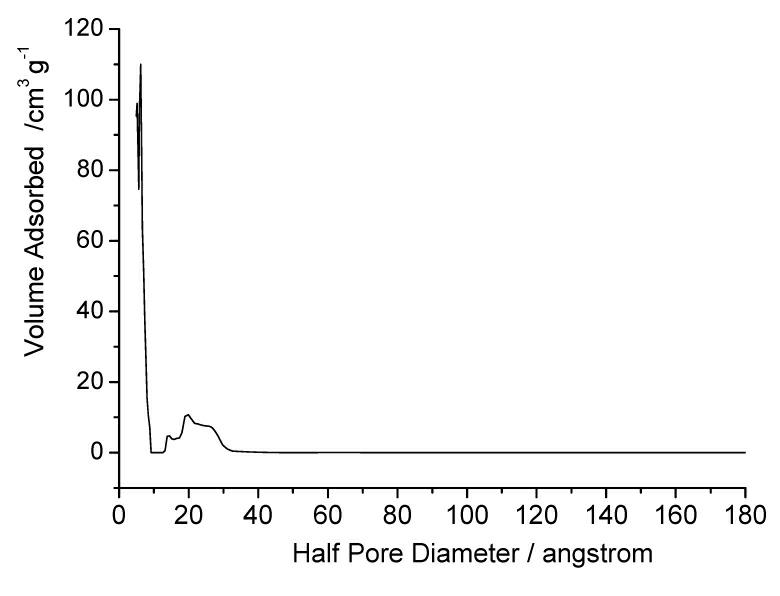

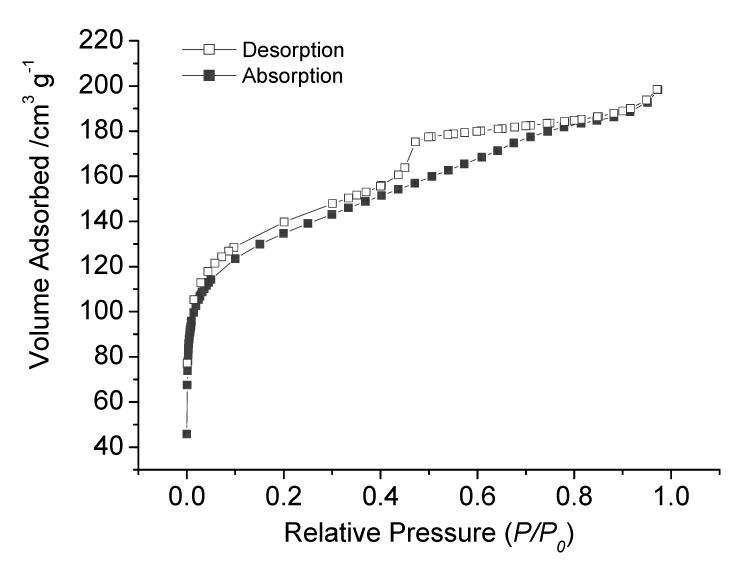

[0069] image 3 with Figure 4 The adsorption-desorption isotherm and pore size distribution diagram of ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com