Hydrogenation conversion integrated method for high-nitrogen and high-aromatic hydrocarbon oil

A technology of hydroconversion and high aromatics, which is applied in the integration of hydro-upgrading process and the integration of two-stage or three-stage hydro-upgrading process of low-temperature coal tar, and can solve problems such as unreported technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

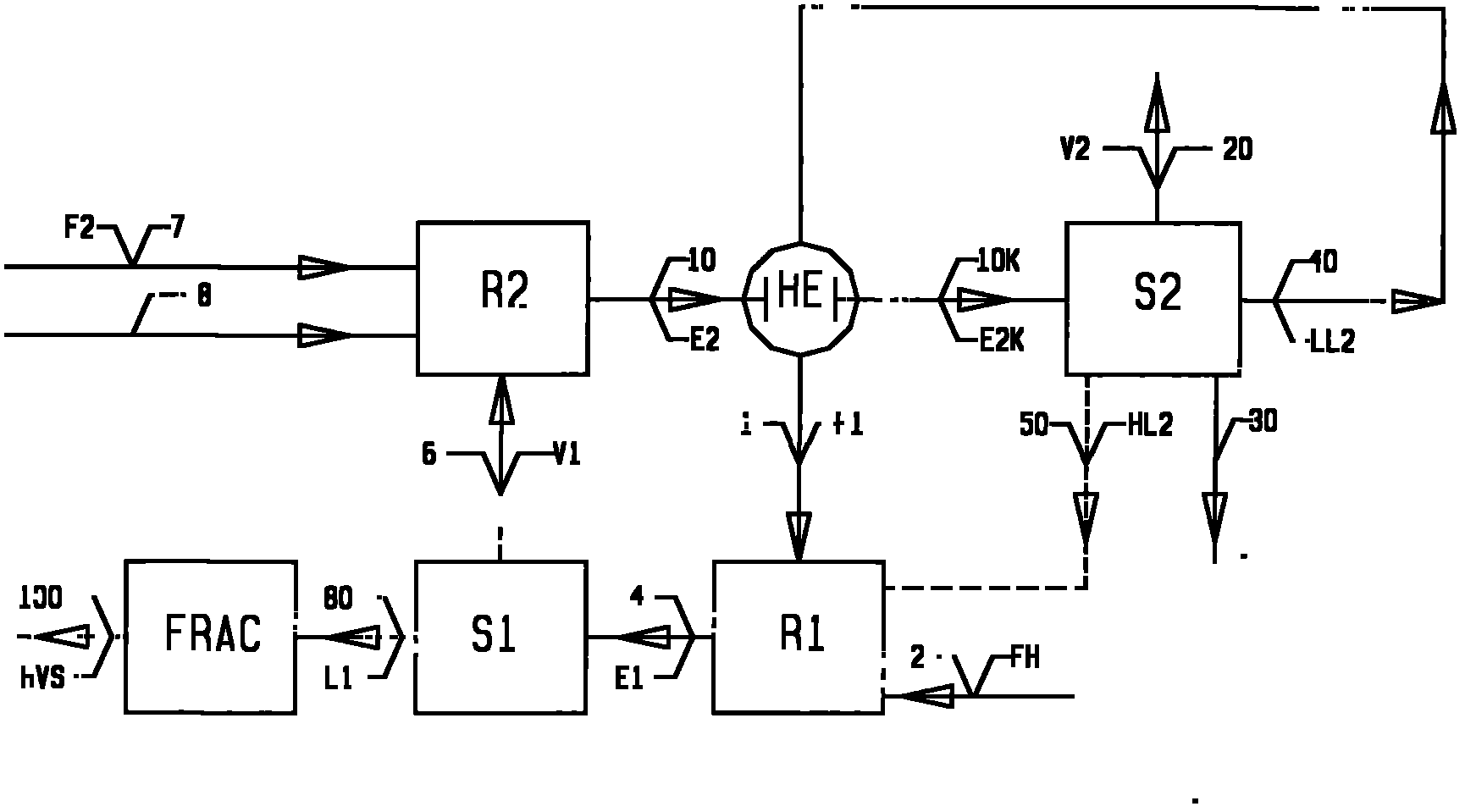

Method used

Image

Examples

Embodiment 1

[0242] The annual start-up of the device is calculated as 8000 hours / year.

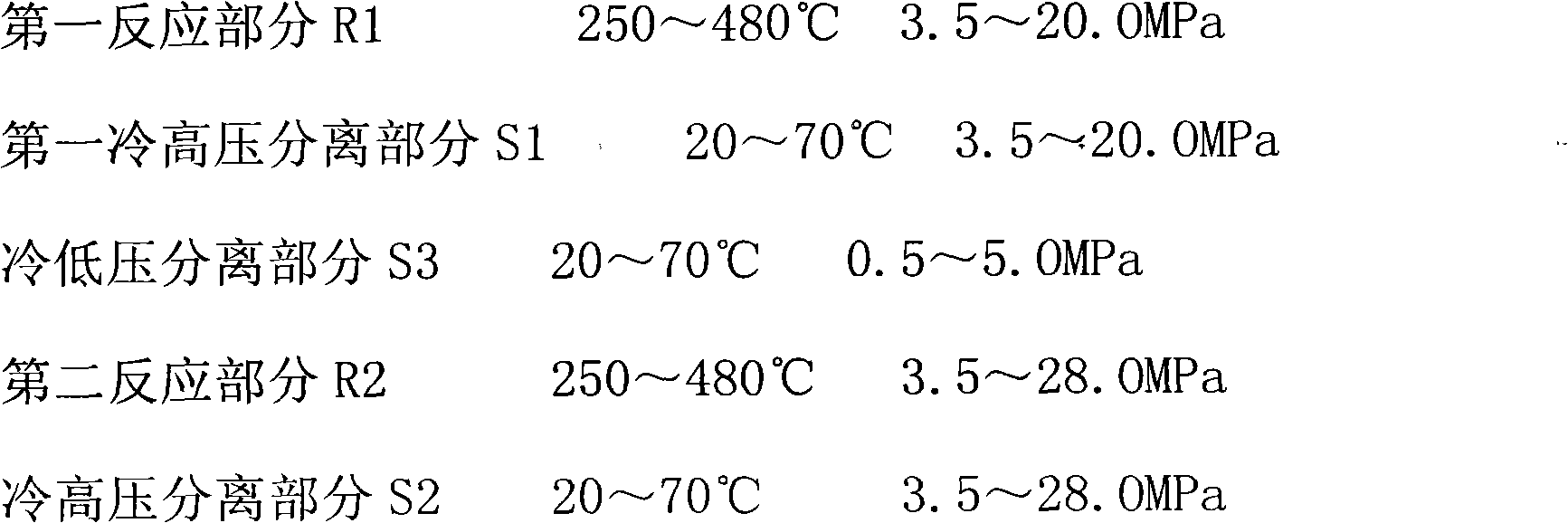

[0243] In the second hydrogenation reaction process, the hydrocarbon feedstock F2 is medium-temperature coal tar distillate oil with a boiling range of 165-375°C, the sulfur content of F2 is 0.45% by weight, the nitrogen content is 0.57% by weight, and the flow rate of F2 is 30t / h. The unit hydrogen consumption (including dissolved hydrogen) of process raw material hydrocarbon is 4.65% (15510Nm 3 / h).

[0244] The hydrogenation reaction conditions of the first-stage hydrogenation upgrading process are: high pressure conditions with a temperature of 320-400°C and a pressure of 16.0-18.0MPa, and the hydrogen volume at the inlet of the first reactor is 61870Nm 3 / h (the volume ratio of hydrogen to oil is 2000), the first-stage hydro-upgrading process uses catalyst beds such as hydrodemetallization, deoxidation, olefin saturation, desulfurization, denitrogenation, and aromatic saturation.

[0245] The F...

Embodiment 2

[0259] Based on Example 1, the separation part of the second hydrogenation reaction effluent E2 adopts a hot high-pressure separation process, the temperature of the second hot high-separator is 260 ° C, and the second hot high-separation oil HL2 and the second cold high-separation oil LL2 enter the first In the first reaction part, the first reactor is jointly modified.

Embodiment 3

[0261] Based on Example 2, the second hydrocarbon feedstock F2 is a medium-temperature coal tar distillate with a boiling range of 165-505°C, and the F2 hydroconversion process adopts a three-stage hydroconversion process, the first stage (the second hydrogenation reaction part R2) It is the hydrogenation upgrading process, the second stage (the first hydrogenation reaction part R1) is the supplementary hydrogenation refining process, and the third stage (the third hydrogenation reaction part R3) is the gentle hydrogenation of the wax oil obtained from the fractionation part FRAC During the cracking process, the third hydrogenated oil E3 enters the first hydrogenation reaction part R1. The operating pressure of the third hydrogenation reaction part R3 is higher than the operating pressure of the first hydrogenation reaction part R1 by 0.3 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com