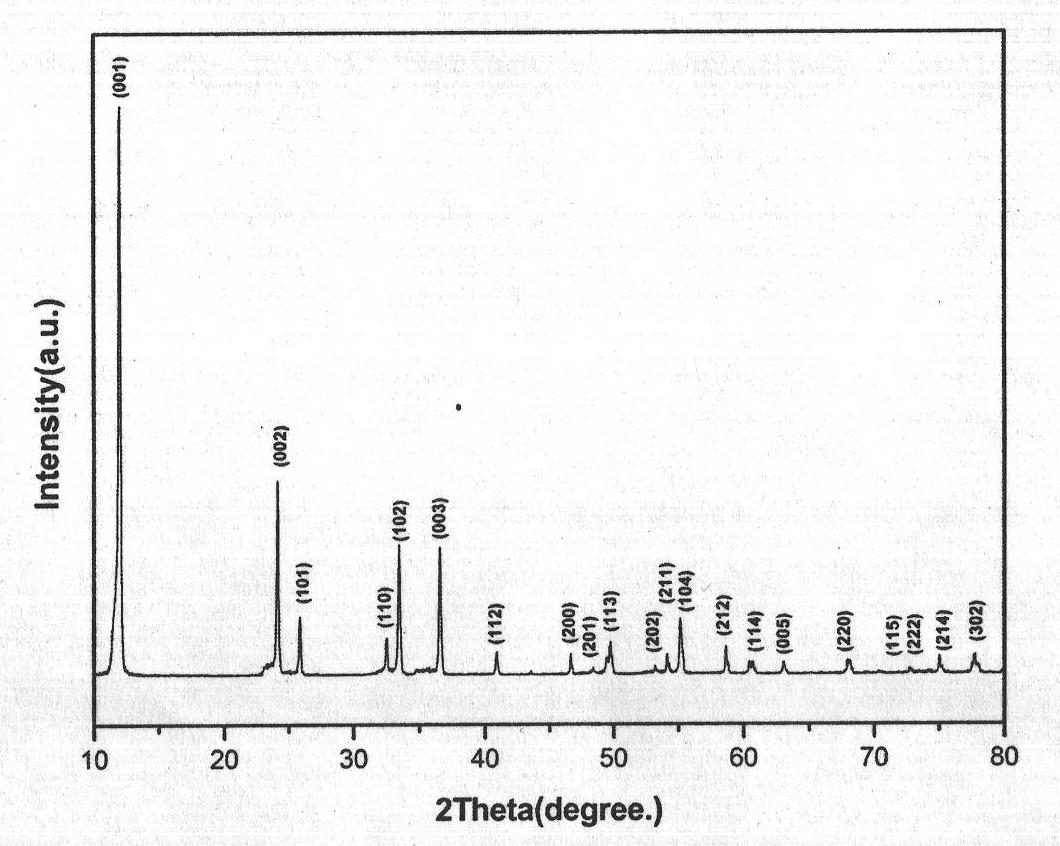

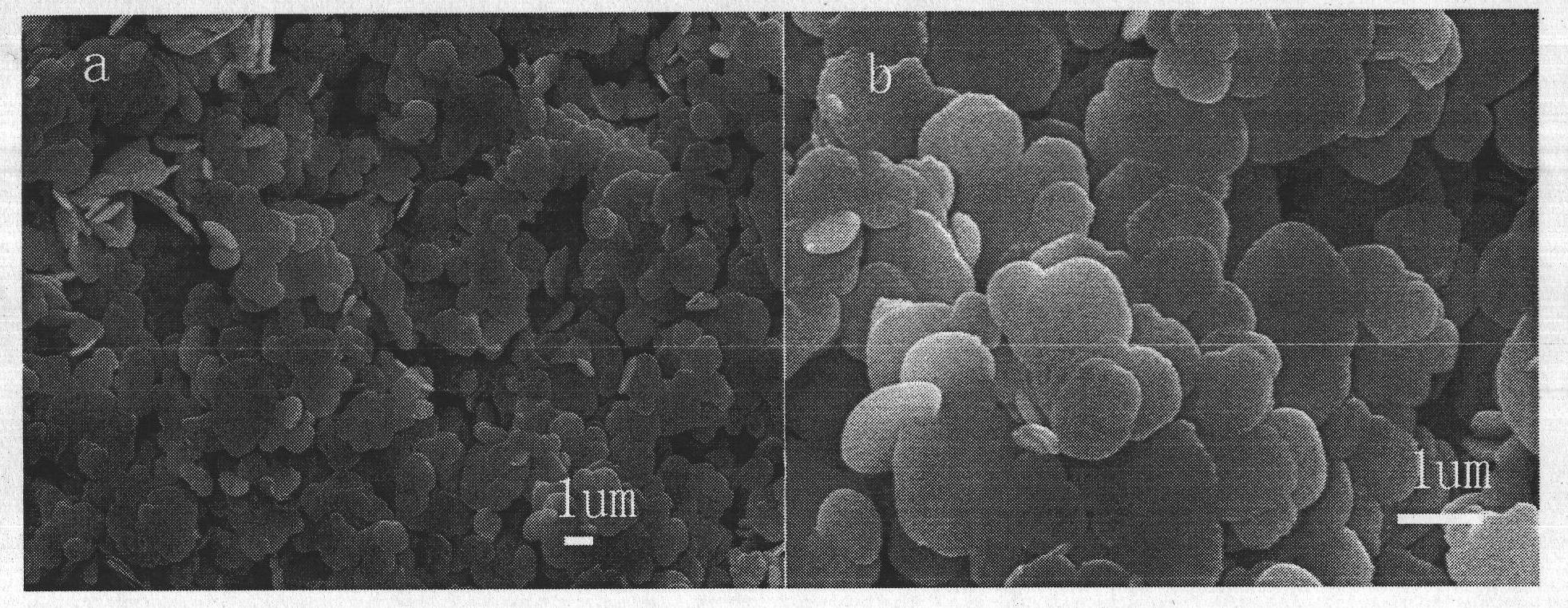

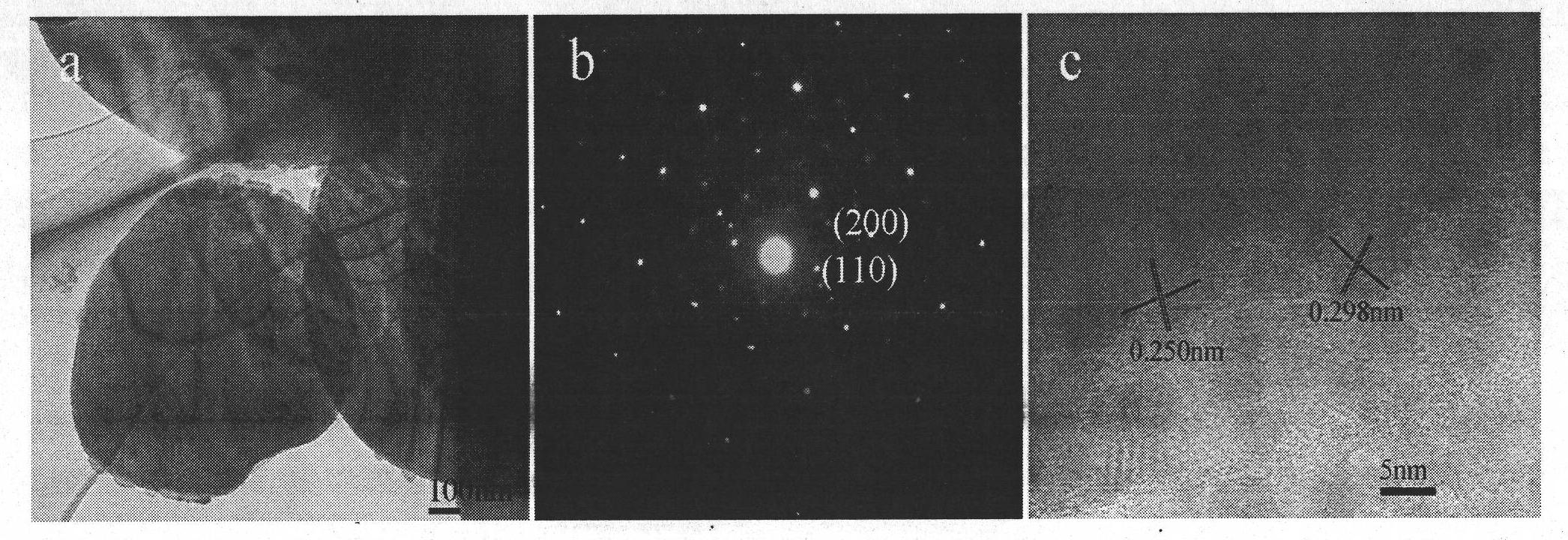

Method for preparing BiOCl monocrystalline nano-chip

A technology of bismuth oxychloride and single crystal nano-sheets, which is applied in the field of preparing bismuth oxychloride single-crystal nanosheets, and can solve the problems that single-crystal nanosheets have not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] ① The raw material BiCl 3 (Purity is mass percentage ≥ 99.1%), KBH 4 (purity is mass percent ≥ 98.0%), put into deionized water and dehydrated ethanol mixed solution (30ml) according to molar ratio 3 / 5, carry out stirring reaction, deionized water and dehydrated alcohol mixed volume ratio are 1 / 4 ; ②Then, the mixed solution is poured into the PTFE liner, the filling volume is 2 / 3, put on the steel jacket and keep the temperature at 200°C for 24 hours; ③Finally, the autoclave is cooled to room temperature, and the reaction product is collected , cleaning, separating, finally collecting and drying to obtain bismuth oxychloride single crystal nanosheets.

Embodiment 2

[0023] ① The raw material BiCl 3 (Purity is mass percentage ≥ 99.1%), KBH 4 (purity is mass percent ≥ 98.0%), put into deionized water and dehydrated ethanol mixed solution (20ml) according to molar ratio 3 / 5, carry out stirring reaction, deionized water and dehydrated alcohol mixed volume ratio are 1 / 4 ; ②Then, the mixed solution is poured into the PTFE liner, the filling amount is 4 / 9, put on the steel jacket and keep at a temperature of 200°C for 24 hours; ③Finally, the autoclave is cooled to room temperature, and the reaction product is collected , cleaning, separating, finally collecting and drying to obtain bismuth oxychloride single crystal nanosheets.

Embodiment 3

[0025] ① The raw material BiCl 3 (Purity is mass percentage ≥ 99.1%), KBH 4 (purity is mass percent ≥ 98.0%), put into deionized water and dehydrated ethanol mixed solution (24ml) according to molar ratio 3 / 5, carry out stirring reaction, deionized water and dehydrated alcohol mixed volume ratio are 1 / 3 ; ②Then, the mixed solution is poured into the PTFE liner, the filling volume is 8 / 15, put on the steel jacket and keep at a temperature of 200°C for 24 hours; ③Finally, the autoclave is cooled to room temperature, and the reaction product is collected , cleaning, separating, finally collecting and drying to obtain bismuth oxychloride single crystal nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com