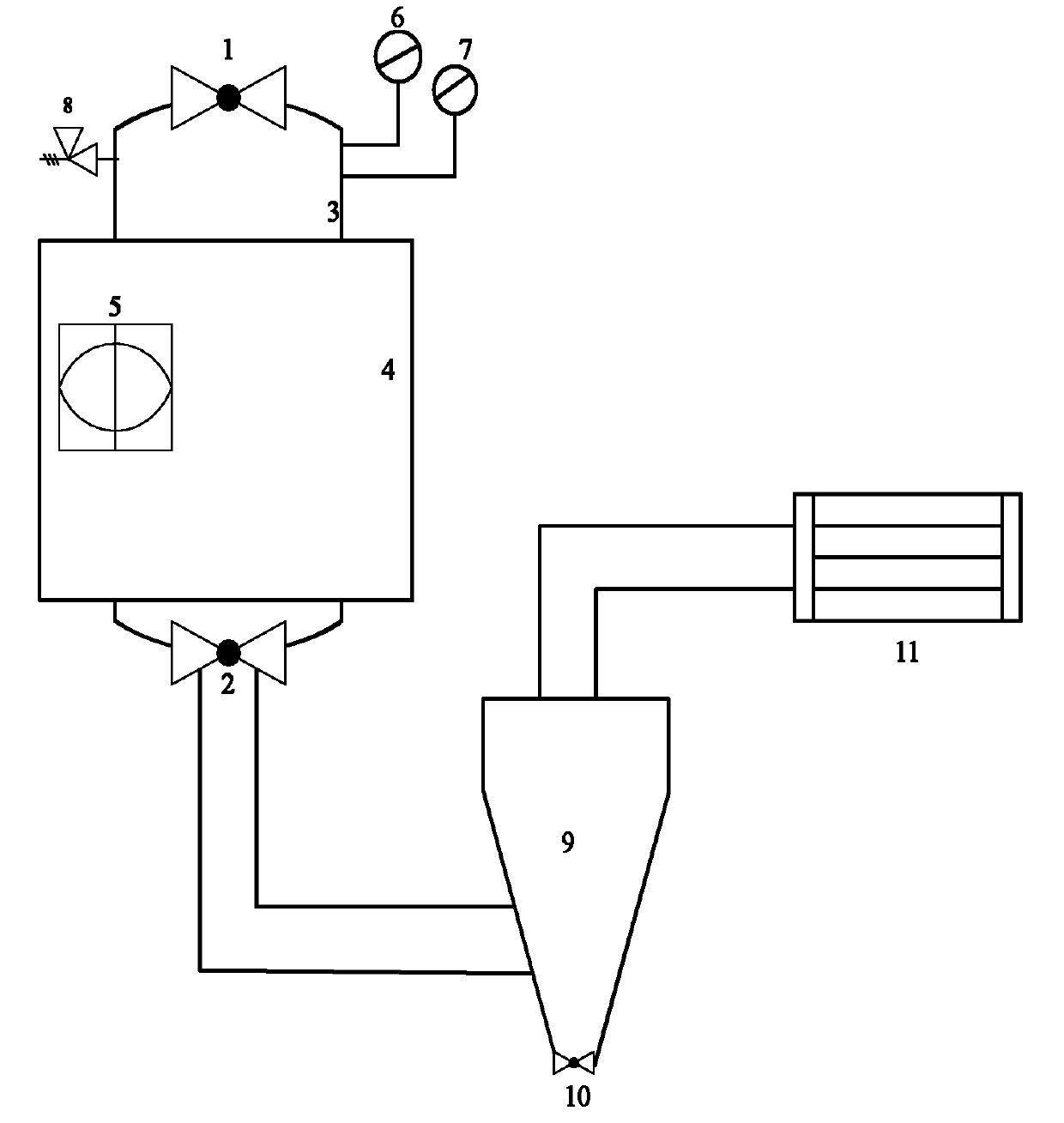

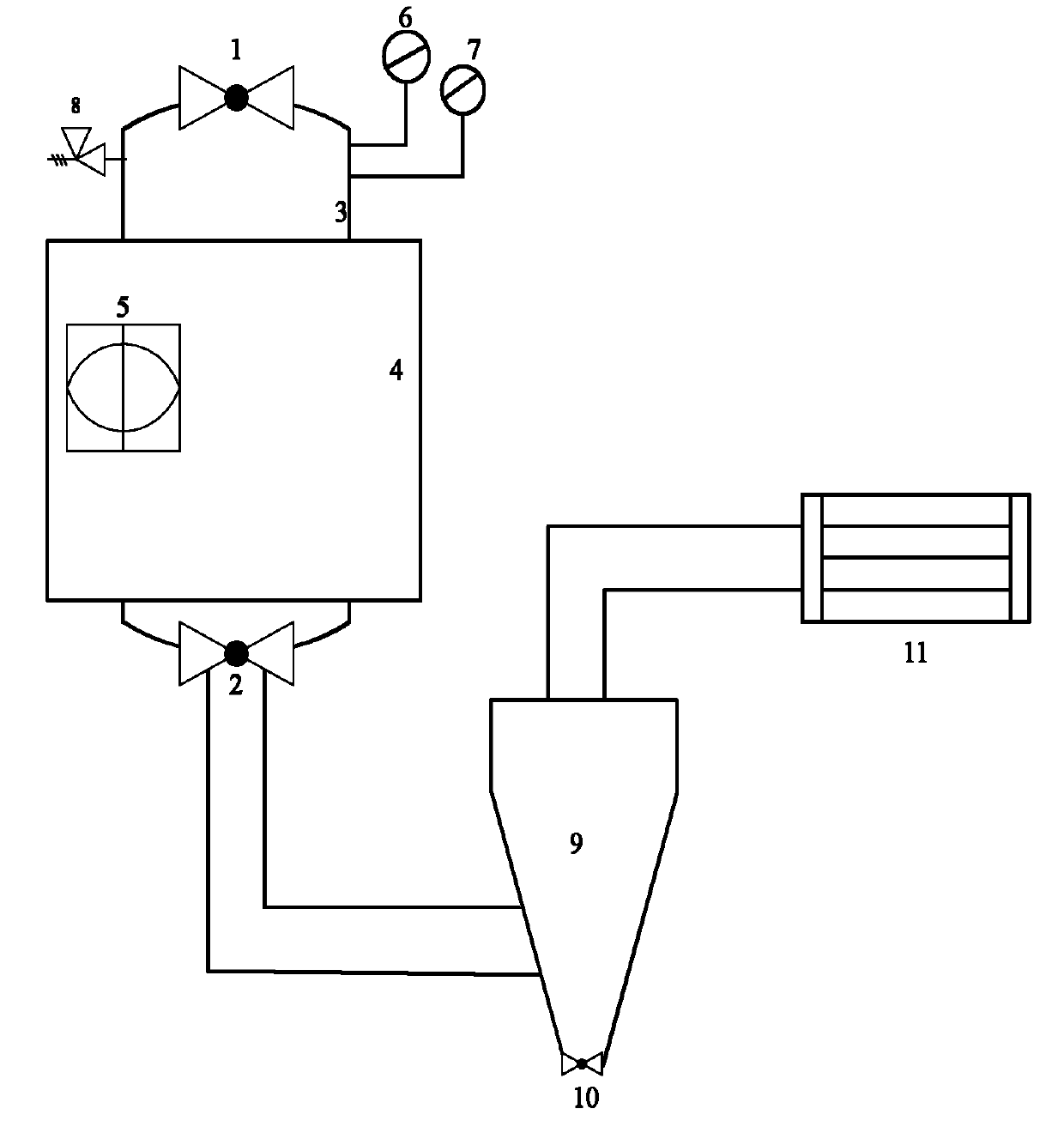

Microwave steam explosion device

A steam explosion device, microwave technology, applied in the chemical/physical/physical chemical process of energy application, raw material pretreatment, chemical instruments and methods, etc., can solve the problems of unstable boiler steam supply and high energy consumption of steam explosion equipment, To achieve the effect of facilitating the analysis of steam explosion mechanism, avoiding manual operation and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Microwave cavity 5L. Cut the outdoor air-dried corn stalks into 1-2cm blocks (wherein the water content is 14%), weigh 200g (wet weight), add 144g of water to make the water content 50%, after the moisture is evenly absorbed, carry out Feed valve 1 is put into tank body 3, and feed inlet ball valve 1 is closed. Set the microwave at 200°C (about 1.5MPa) for 5 minutes, and turn on the power switch. When the time is up, the microwave stops heating, and the outlet valve 2 is quickly opened, and the multi-phase materials enter the buffer tank 9 together. After steam-solid separation, the steam enters the condensation system 11 to collect the condensed liquid, and the solid material is released from the buffer tank lower end valve 10. release. The hemicellulose recovery rate of steam-exploded corn stalks was determined to be 65.2%, and the enzymatic hydrolysis rate of cellulose was 59.1%. The temperature and pressure curves displayed in real time can be used for three tran...

Embodiment 2

[0016] Microwave cavity 5L. Cut the outdoor air-dried corn stalks into 1-2cm blocks (wherein the water content is 14%), weigh 200g (wet weight), add 144g of water to make the water content 50%, after the moisture is evenly absorbed, carry out Feed valve 1 is put into tank body 3, and feed inlet ball valve 1 is closed. Set the microwave at 190°C (about 1.2MPa) for 8 minutes, and turn on the power switch. When the time is up, the microwave stops heating, and the outlet valve 2 is quickly opened, and the multi-phase materials enter the buffer tank 9 together. After steam-solid separation, the steam enters the condensation system 11 to collect the condensed liquid, and the solid material is released from the buffer tank lower end valve 10. release. The hemicellulose recovery rate of steam-exploded corn stalks was determined to be 68.2%, and the enzymatic hydrolysis rate of cellulose was 63.1%. The temperature and pressure curves displayed in real time can be used for three tran...

Embodiment 3

[0018] Microwave cavity 5L. Cut the outdoor air-dried corn stalks into 1-2cm blocks (wherein the water content is 14%), weigh 200g (wet weight), add 65g of water to make the water content 35%, and after the moisture is evenly absorbed, carry out Feed valve 1 is put into tank body 3, and feed inlet ball valve 1 is closed. Set the microwave at 190°C (about 1.2MPa) for 8 minutes, and turn on the power switch. When the time is up, the microwave stops heating, and the outlet valve 2 is quickly opened, and the multi-phase materials enter the buffer tank 9 together. After steam-solid separation, the steam enters the condensation system 11 to collect the condensed liquid, and the solid material is released from the buffer tank lower end valve 10. release. The hemicellulose recovery rate of steam-exploded corn stalks was determined to be 83.2%, and the enzymatic hydrolysis rate of cellulose was 69.3%. The temperature and pressure curves displayed in real time can be used for three t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com