Quartz/quartz-boron nitride high-temperature wave-permeable material and preparation method thereof

A technology of high-temperature wave-transmitting and boron nitride, applied in the field of high-temperature wave-transmitting materials and their preparation, can solve problems such as thermal shock resistance and insufficient reliability, and achieve improved mechanical properties and ablation resistance, good bearing capacity, and mechanical properties. and good effect on ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The quartz / quartz-boron nitride high-temperature wave-transmitting material of this embodiment has a chemical formula of SiO 2f / SiO 2 -BN; contains about 45% volume fraction of quartz fibers, about 27% volume fraction of SiO 2 , about 15% volume fraction of BN.

[0024] Preparation:

[0025] (1) Preparation of quartz / quartz ceramic green body

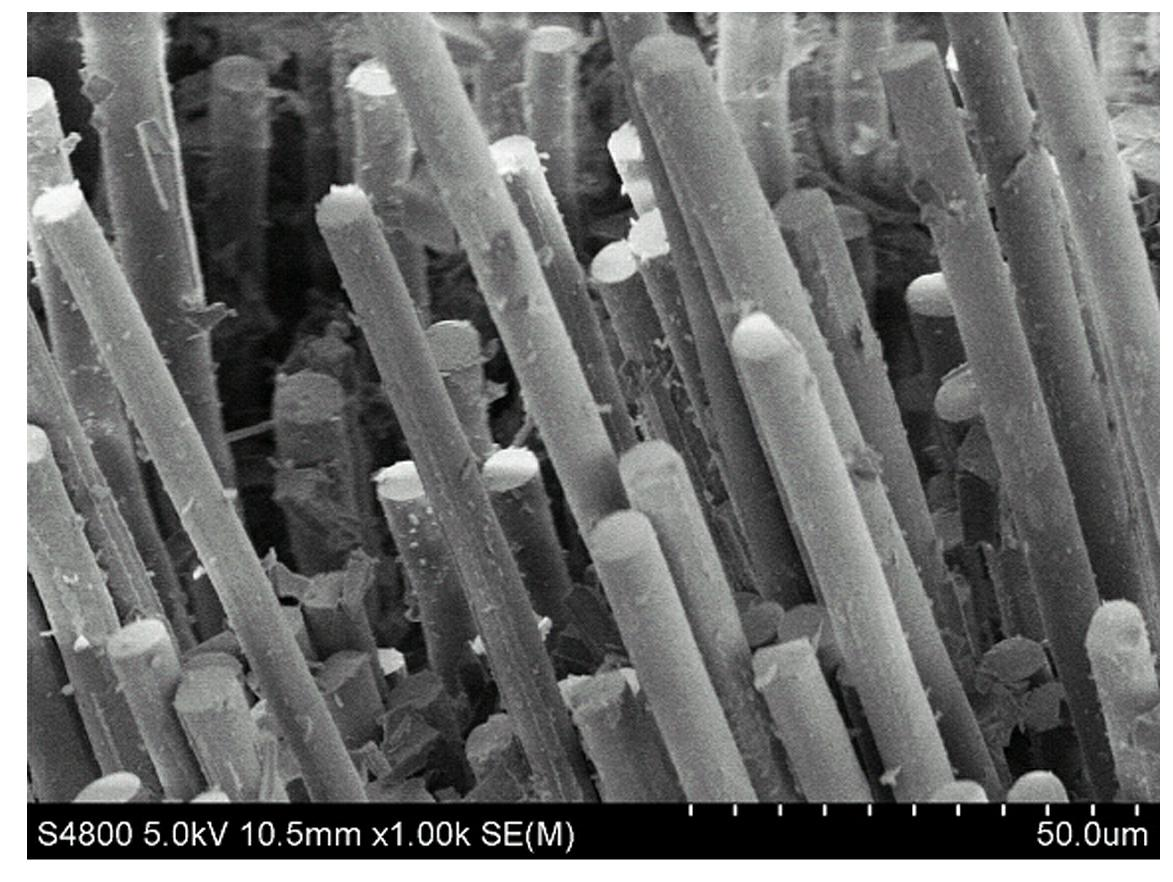

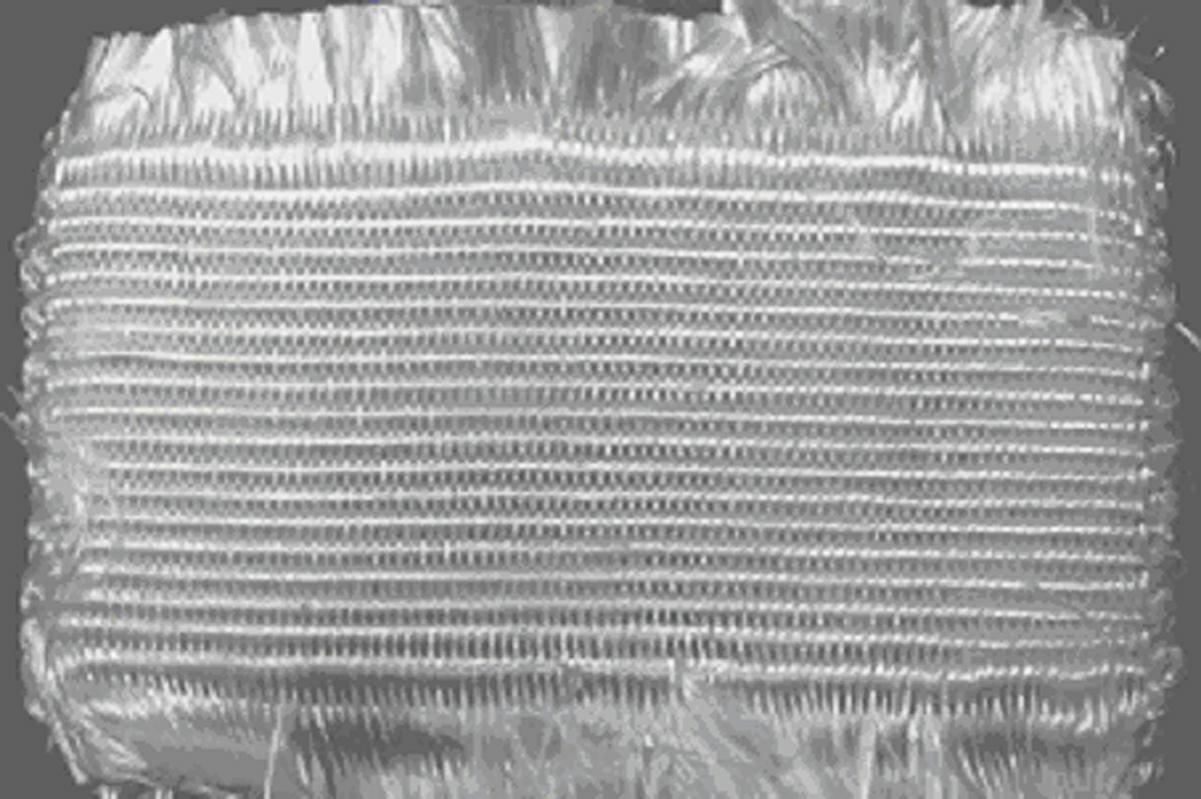

[0026] The silica sol was impregnated into a 2.5D quartz fiber fabric (fiber volume fraction 43%) flat sample (such as figure 1 shown), and then placed in an oil bath at 80°C for 12 hours to complete the sol-gel process; then heated to 200°C, kept for 2 hours, and solidified; finally ceramicized in a muffle furnace at 850°C , holding for 1h, to obtain quartz / quartz ceramics (SiO 2f / SiO 2 ) the initial sample of the green body composite material; repeat the impregnation-sintering process 6 times to obtain a density of about 1.60g / cm 3 , Quartz / quartz ceramic green body with a porosity of about 30%;

[0027] (2) Surface ...

Embodiment 2

[0033] The quartz / quartz-boron nitride high-temperature wave-transmitting material of this embodiment has a chemical formula of SiO 2f / SiO 2 -BN; contains about 45% volume fraction of quartz fibers, about 27% volume fraction of SiO 2 , about 15% volume fraction of BN.

[0034] Preparation:

[0035] (1) Preparation of quartz / quartz ceramic green body

[0036] Immerse the silica sol into a 2.5D quartz fiber fabric flat sample under vacuum conditions, and place it in an oil bath at 80°C for 12 hours to complete the sol-gel process; then heat it to 200°C, keep it warm for 2 hours, and solidify it ; Finally, it was ceramicized in a muffle furnace at 800° C. and kept for 1 hour to obtain a quartz / quartz-boron nitride composite material. The impregnation-sintering process was repeated 9 times.

[0037] Step (2) is the same as step (2) in Example 1;

[0038] Step (3) is the same as step (3) in Example 1.

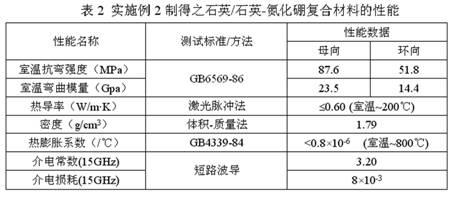

[0039] The resulting density is about 1.79g / cm 3 of quartz / quartz-boro...

Embodiment 3

[0042] The quartz / quartz-boron nitride high-temperature wave-transmitting material of this embodiment has a chemical formula of SiO 2f / SiO 2 -BN; contains about 45% volume fraction of quartz fibers, about 27% volume fraction of SiO 2 , about 16% volume fraction of BN.

[0043] Preparation:

[0044] Step (1) is the same as step (1) in Example 1;

[0045] Step (2) is the same as step (2) in Example 1;

[0046] (3) Dipping-cracking

[0047] Immerse the saturated ethanol solution of boric acid and urea into the quartz / quartz ceramic green body processed in step (2) under vacuum, and then place it in an oven at 100°C for 10 hours to cure and shape; 2 Under the atmosphere, the ceramicization is completed in the cracking furnace, the cracking temperature is 900°C, and the holding time is 1h to obtain SiO 2f / SiO 2 -Preliminary sample of BN composite material. The impregnation-lysis process was repeated 2 times. The obtained density is about 1.82g / cm 3 of quartz / quartz-boron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com