Film transistor substrate and display device thereof

A technology for thin film transistors and substrates, applied in transistors, electro-solid devices, semiconductor devices, etc., can solve the problems of hindering metal layers, reducing productivity, increasing manufacturing costs, etc., and achieving the effects of low contact resistivity, high adhesion and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] In this example, the contact resistivity and adhesion between the Cu alloy layer (laminated structure) and the semiconductor layer will be discussed.

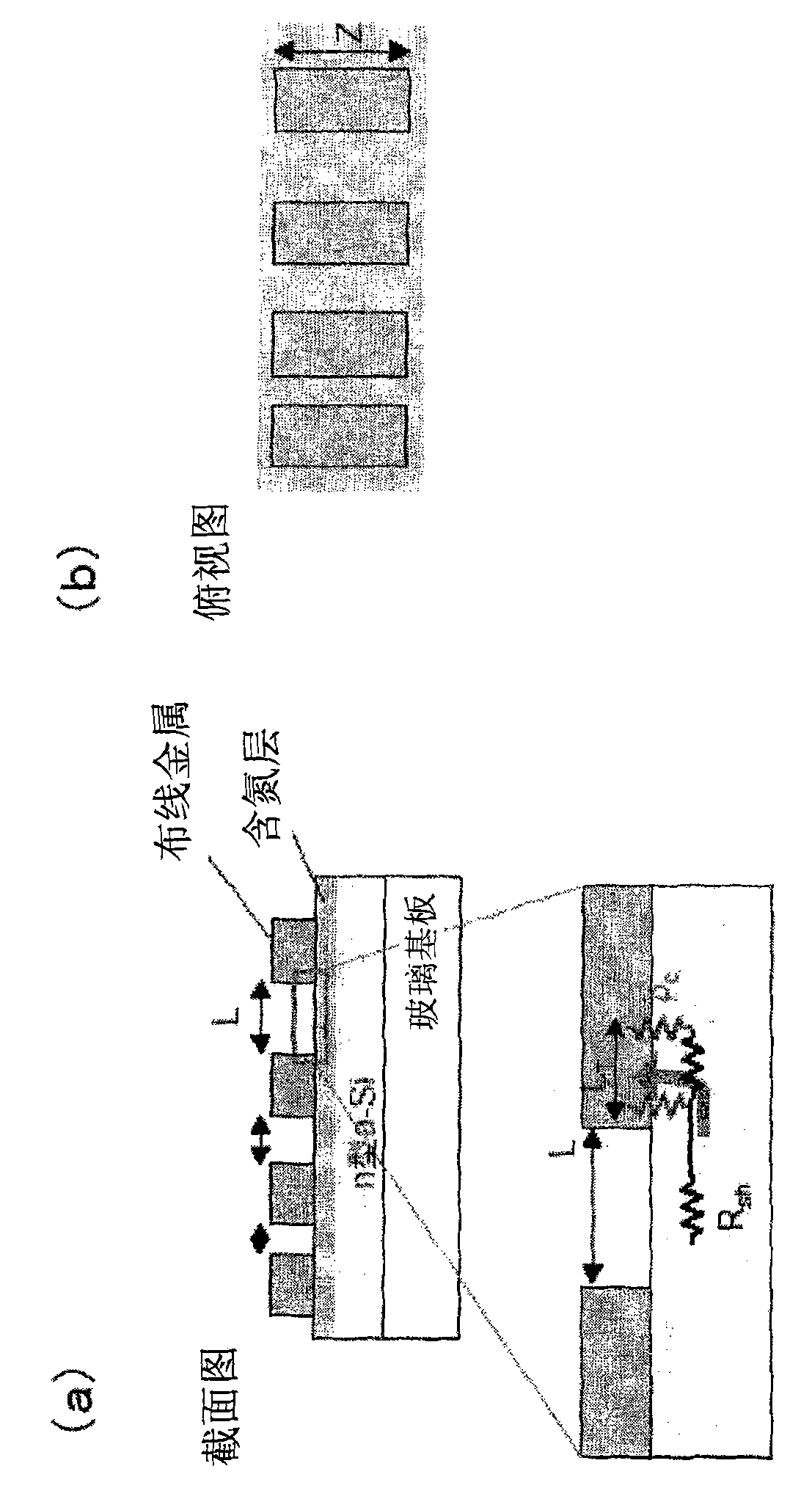

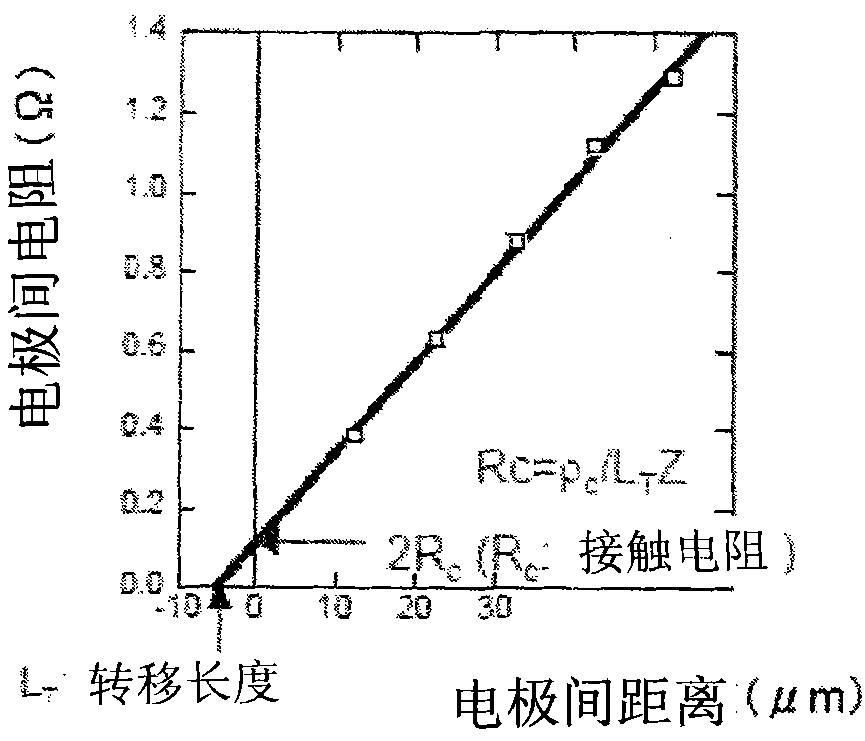

[0093] (1) Measurement of contact resistivity with semiconductor layer

[0094] In order to investigate the contact resistivity between the Cu alloy layer and the semiconductor layer, a TLM (TransferLengthMethod) element was produced, according to figure 2 , 3 The TLM method is shown for the determination of contact resistivity. First, a method of fabricating a TLM element will be described.

[0095] First, a low-resistance amorphous silicon film doped with an impurity (P) with a thickness of about 200 nm is formed on a glass substrate by plasma CVD to a thickness of about 200 nm. Next, in the same plasma CVD apparatus, only oxygen was supplied to generate plasma, and the surface of the low-resistance amorphous silicon film was treated with oxygen plasma for 30 seconds to form an oxygen-containing layer. As an oxyge...

Embodiment 2

[0123] In this example, the oxygen-containing layer formed on the surface of the semiconductor layer prevents Cu atoms in the Cu alloy layer from diffusing into the semiconductor layer.

[0124] First, a SiN film with a film thickness of approximately 100 nm is formed on a glass substrate by plasma CVD, and a low-resistance amorphous silicon film (n-a-Si:H layer) doped with impurities (P) with a film thickness of 200 nm is formed thereon. . The film formation temperature of plasma CVD was 320°C.

[0125] Next, only oxygen was supplied into the same chamber of the same plasma CVD apparatus to generate plasma, and the surface of the aforementioned low-resistance amorphous silicon film was treated with oxygen plasma for 10 minutes to form an oxygen-containing layer. As the oxygen plasma device, a measuring device (model: PR41) manufactured by Yamato Science Co., Ltd. was used. The frequency was 13.56 Hz, the input power was 450 W, the film formation temperature was room temperat...

Embodiment 3

[0133] In this example, the influence of the [O] / [Si] ratio in the oxygen-containing layer and the film thickness of the oxygen-containing layer on the contact resistivity and adhesion will be discussed.

[0134] (1) Measurement of the bonding state of O and Si in the oxygen-containing layer

[0135] The preparation of the sample was the same as the adhesion evaluation test of Example 1, except that the Cu alloy layer was used as the first layer: Cu-4atom% Mn (film thickness: 20nm), and the second layer: pure Cu (film thickness: 280nm). . In addition, the oxygen flow rate in the oxygen plasma treatment was 30 sccm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com