Comprehensive recovery method using vacuum pyrolysis oil of wastes like waste circuit boards

A waste circuit board, vacuum pyrolysis technology, applied in the direction of electronic waste recycling, waste fuel, plastic recycling, etc., can solve the problems of ineffective recycling and deep resource utilization, and achieve promotion and application, good environmental benefits, and economic benefits Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

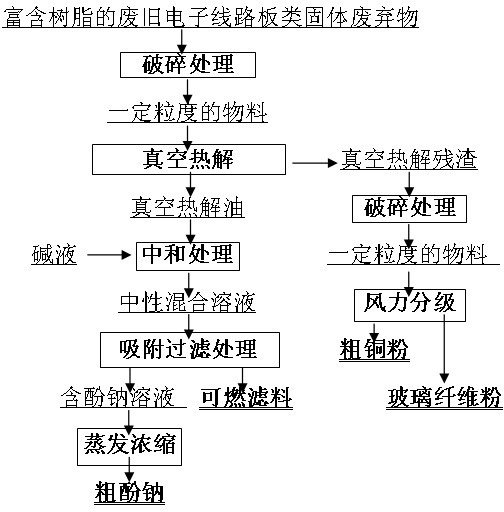

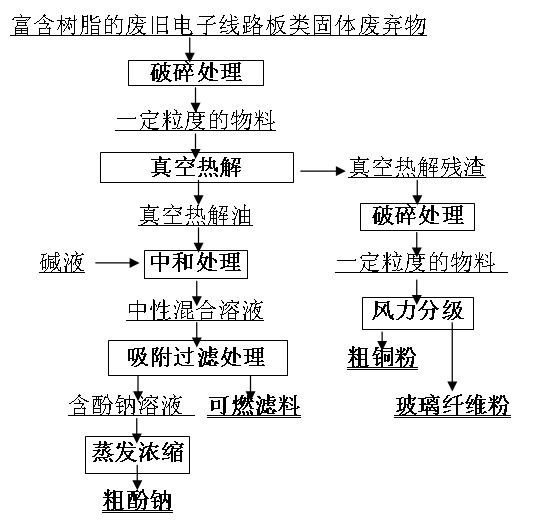

Method used

Image

Examples

Embodiment 1

[0030] 1. Weigh 1 kg of waste electronic circuit boards.

[0031] 2. Obtain 1 kg of circuit board waste with a particle size of 50-100 mm by shearing and crushing.

[0032] 3. Load the scrap into the metal bin.

[0033] 4. Move the charged metal bin into the vacuum pyrolysis furnace and cover the furnace cover.

[0034] 5. Heating and vacuuming, after about half an hour, the temperature is raised to 400°C, and the vacuum degree is 8000Pa.

[0035] 6. Constant temperature response, the reaction time is one hour, and the temperature is stable at 400°C during the reaction process.

[0036] 7. The pyrolysis gas generated during the reaction is led into the cooler for condensation and collection.

[0037] 8. After the reaction, the vacuum pyrolysis furnace is naturally cooled to 100°C, slowly filled with air to break the vacuum to normal pressure, open the furnace cover, take out the metal box, take out about 700 grams of residue, and release 120 grams of vacuum pyrolysis oil fr...

Embodiment 2

[0044] 1. Weigh 2 kg of waste electronic circuit boards.

[0045] 2. Obtain 2 kg of circuit board waste with a particle size of 50-100 mm by shearing and crushing.

[0046] 3. Load the scrap into the metal bin.

[0047] 4. Move the charged metal bin into the vacuum pyrolysis furnace and cover the furnace cover.

[0048] 5. Heating and vacuuming, after about half an hour, the temperature is raised to 500°C, and the vacuum degree is 10000Pa.

[0049] 6. Respond at constant temperature, the reaction time is one and a half hours, and the temperature is stable at 500°C during the reaction process.

[0050] 7. The pyrolysis gas generated during the reaction is led into the cooler for condensation and collection.

[0051] 8. After the reaction, the vacuum pyrolysis furnace is naturally cooled to 100°C, slowly filled with air to break the vacuum to normal pressure, open the furnace cover, take out the metal box, take out about 1450 grams of residue, and release 320 grams of vacuum py...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com