Construction method of kluyveromyces lactis engineering strains for producing ferment rennet

A technology of Kluyveromyces cerevisiae and engineering strains, applied in the directions of microorganism-based methods, biochemical equipment and methods, hydrolase, etc., can solve the problems of inconsistent product properties, bitterness, restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Embodiment 1: The construction method of the rennet-producing Kluyveromyces lactis engineering strain of this embodiment is carried out according to the following steps:

[0017] 1. Design upstream primers and downstream primers according to the gene sequence of K. lactis PMR1 (AJ001018) published in Genebank, and then perform PCR amplification using K. lactis GG799 genomic DNA as a template to obtain K. lactis GG799 the PMR1 gene;

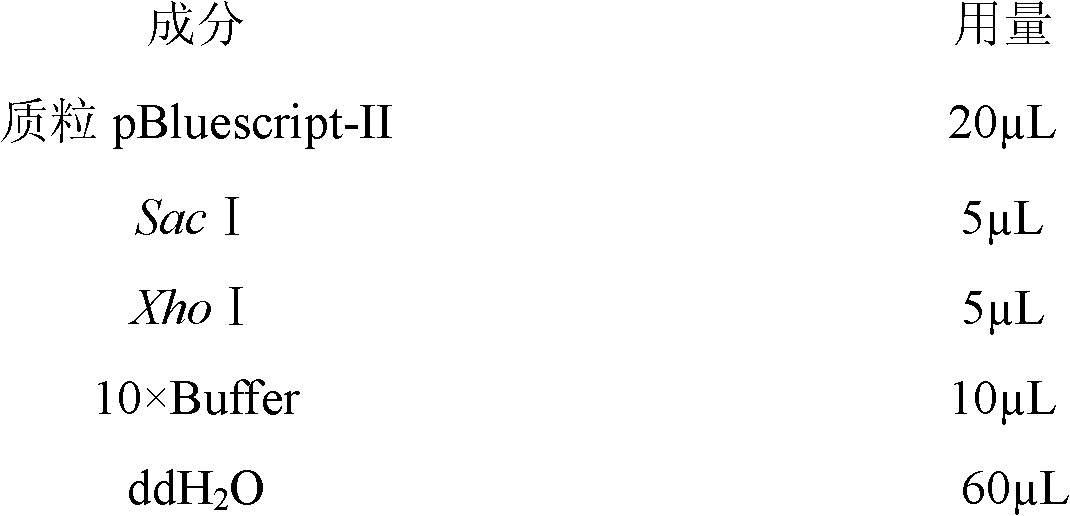

[0018] 2. The PMR1 gene of Kluyveromyces lactis GG799 and the plasmid pBluescript-II were simultaneously digested with Sac I and Xho I, and the desired target fragment was recovered and ligated to obtain the ligated product pBluescript-II-PMR1;

[0019] 3. The connection product pBluescript-II-PMR1 was transformed into Escherichia coli JM109 competent cells, and then spread on ampicillin-resistant LB solid medium for culture, and the positive clones were picked for culture in liquid shake flasks, and then the recombinant plasmid pBluescript...

specific Embodiment approach 2

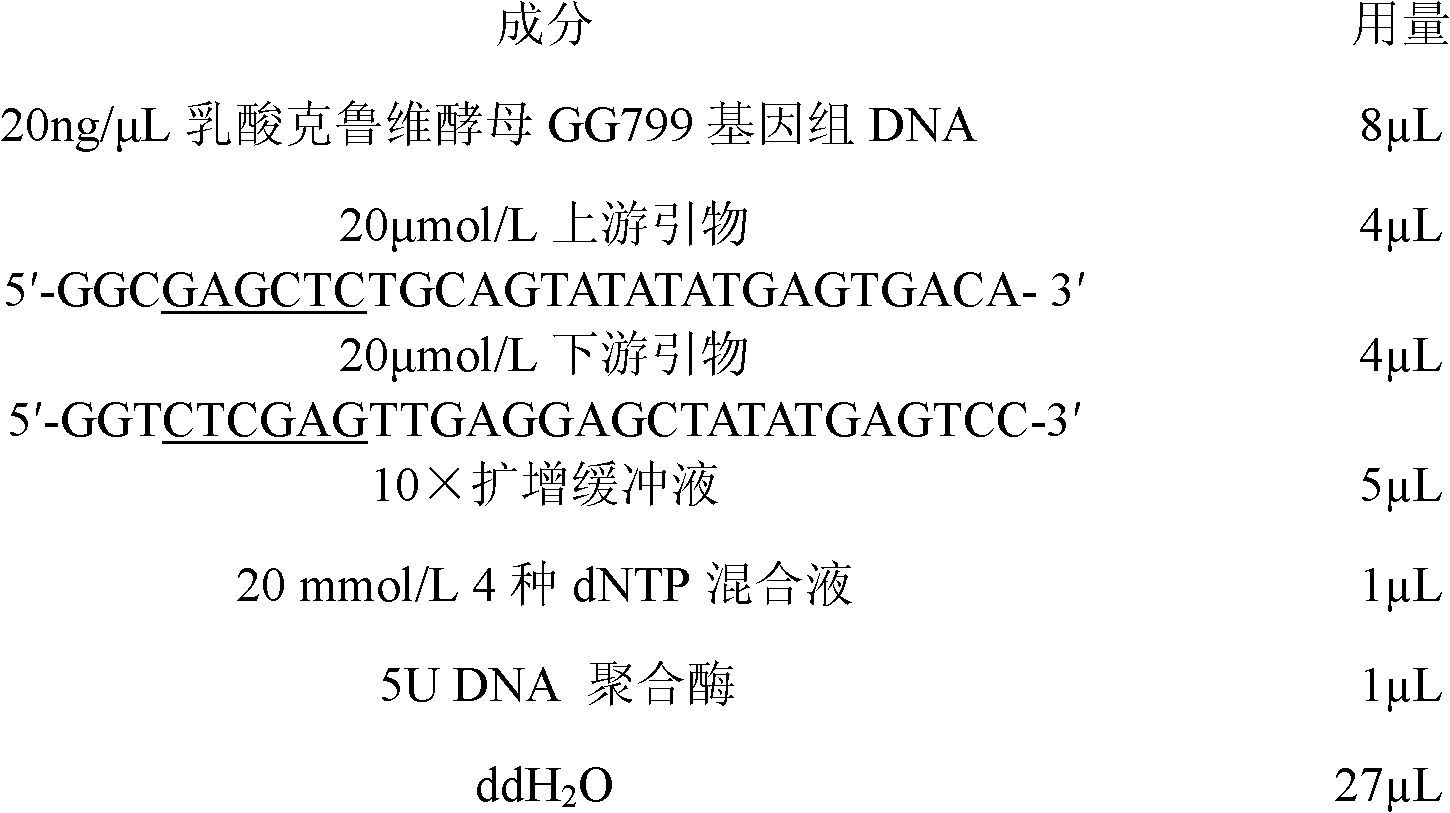

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the reaction system for PCR amplification in step one is a 50 μL reaction system, which consists of the following components:

[0032]

[0033] PCR amplification conditions were: 95°C pre-denaturation for 10 min, 95°C denaturation for 45 s, 55°C annealing for 30 s, 72°C extension for 2 min, a total of 30 cycles, 72°C extension for 10 min, and 4°C incubation. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

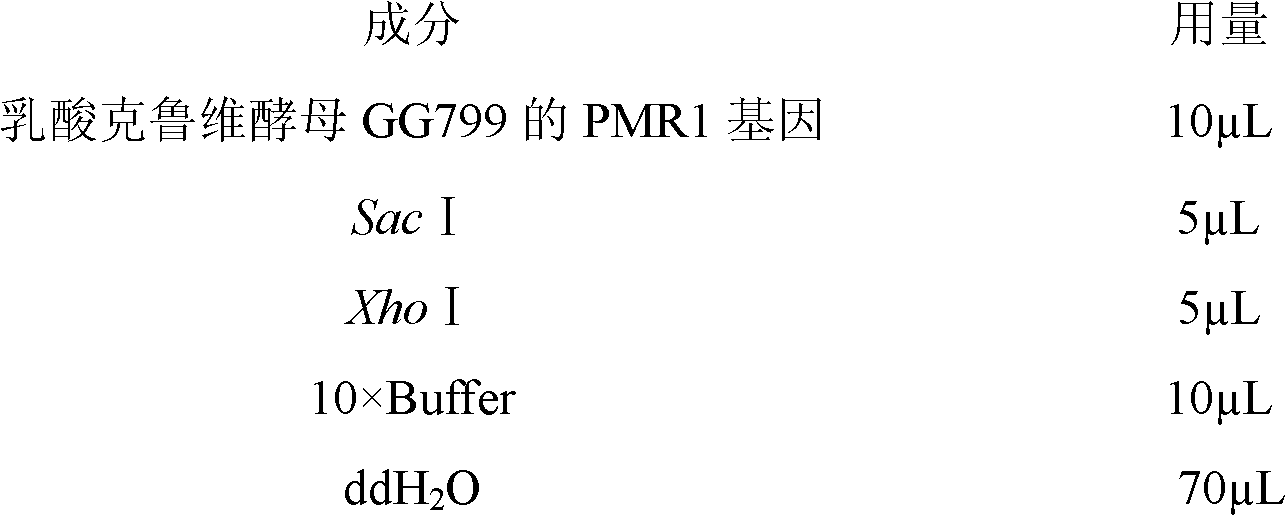

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the double enzyme digestion system of the PMR1 gene of Kluyveromyces lactis GG799 in step 2 is as follows:

[0035]

[0036] Enzyme digestion conditions: 37 ° C, 1.5 ~ 2h. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com