Process for producing plant root growth regulator by cow dropping

A cow dung, ammonium sulfite technology, applied in plant growth regulators, plant growth regulators, biocides, etc., can solve the problems of long time period, low efficiency, waste of coal and phosphate rock resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

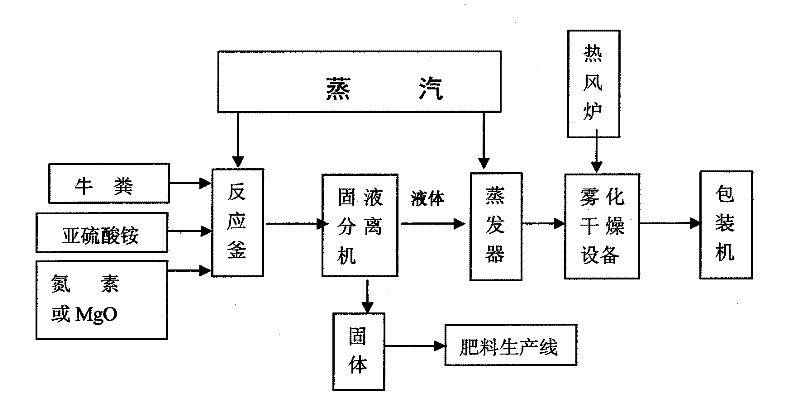

Image

Examples

Embodiment Construction

[0006] Use 100% ammonium sulfite to add 20% of the absolute dry cow dung, and add 4% (or MgO 4%) of nitrogen (urea, ammonium bicarbonate, ammonia) based on pure ammonia, liquid ratio 1:4, according to the reactor Calculate the amount of dry cow dung and the content of ammonium sulfite to add ammonium sulfite and nitrogen (or MgO), add it to the reactor and mix it evenly, then pass it into steam, raise the pressure to 0.7MPa within 30 minutes and maintain the pressure. After reacting at a constant temperature of 140~150℃ for 3 hours, the mixed and reacted materials are then passed through a solid-liquid separator to separate the ammonium lignosulfonate dissolved in water; the liquid is then concentrated to 40~42% through an evaporator device Concentration, and then process the ammonium lignosulfonate dissolved in water into a solid powder through an atomizing drying device, and pack it into a 25KG product per bag with an inner film bag, which is the ammonium lignosulfonate-plant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com