Method for preparing hexagonal pyramid-like zinc oxide by low temperature combustion synthesis method

A technology of low-temperature combustion synthesis and hexagonal pyramid, which is applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., and can solve the problem of easy powder agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

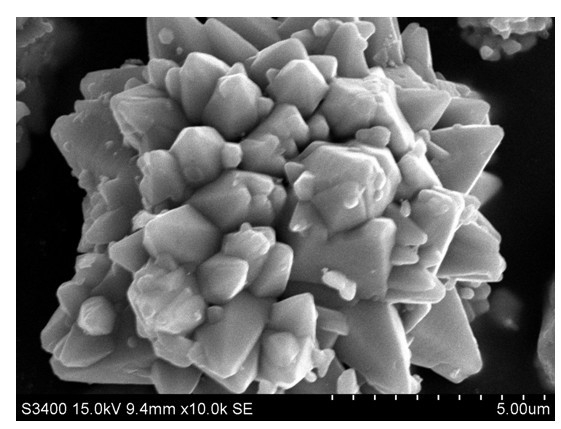

[0017] Mix 0.1mol (29.75g) of zinc nitrate, 0.3mol (23.12g) of ammonium acetate and 0.01mol (0.80g) of ammonium nitrate, add 0.3mol of deionized water to grind into a colloid, and use an ultrasonic processor with a power of 150W and a frequency of 20kHz. Ultrasonic dispersion for 5 minutes; the obtained colloid was put into a muffle furnace for combustion synthesis, and the combustion synthesis temperature was 550 0 C, the product of combustion synthesis is ground to disperse; the powder after grinding is at 400 0 Annealed under C condition for 3 hours, the zinc oxide powder body with hexagonal pyramid structure in Fig. 1 was obtained.

Embodiment 2

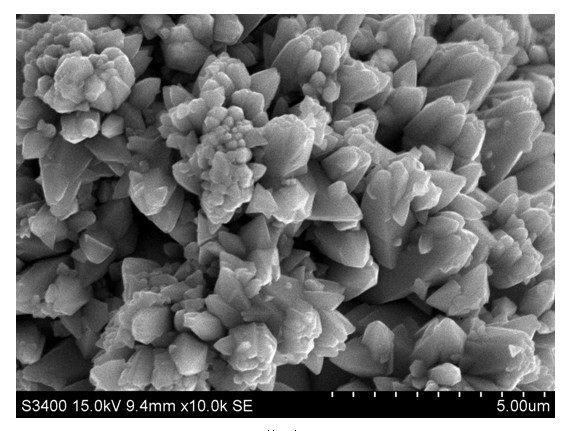

[0019] Grind 0.1mol (29.75g) of zinc nitrate, 0.5mol (38.54g) of ammonium acetate and 0.08mol (6.40g) of ammonium nitrate into a colloid with 0.5mol of deionized water, and perform ultrasonication with an ultrasonic processor with a power of 150W and a frequency of 20kHz Disperse for 5 minutes; the obtained colloid is put into a muffle furnace for combustion synthesis, and the combustion synthesis temperature is 600 0 C, the product of combustion synthesis is ground to disperse; the powder after grinding is at 550 0 Annealed for 3 hours under the condition of C to obtain the zinc oxide powder with hexagonal pyramid structure in Fig. 2 .

Embodiment 3

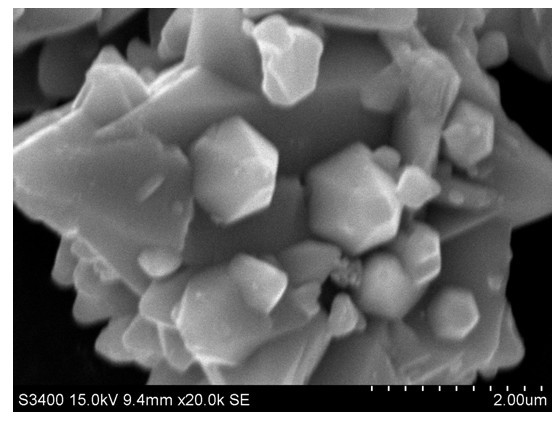

[0021] Grind 0.1mol (29.75g) of zinc nitrate, 0.7mol (53.96g) of ammonium acetate and 0.15mol (12.01g) of ammonium nitrate into a colloid with 0.7mol of deionized water, and perform ultrasonication with an ultrasonic processor with a power of 150W and a frequency of 20kHz Disperse for 5 minutes; the obtained colloid is put into a muffle furnace for combustion synthesis, and the combustion synthesis temperature is 650 0 C, the product of combustion synthesis is ground to disperse; the powder after grinding is at 700 0 Annealed for 3 hours under the condition of C to obtain the zinc oxide powder with hexagonal pyramid structure in Fig. 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com