Reinforced concrete material with high corrosion resistance and preparation method thereof

A technology for reinforced concrete and cementitious materials, applied in the field of concrete materials, can solve the problems of reduced structural bearing capacity, concrete expansion cracks, concrete structure damage, etc., and achieves the effects of good corrosion resistance of steel bars, high compactness and good construction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

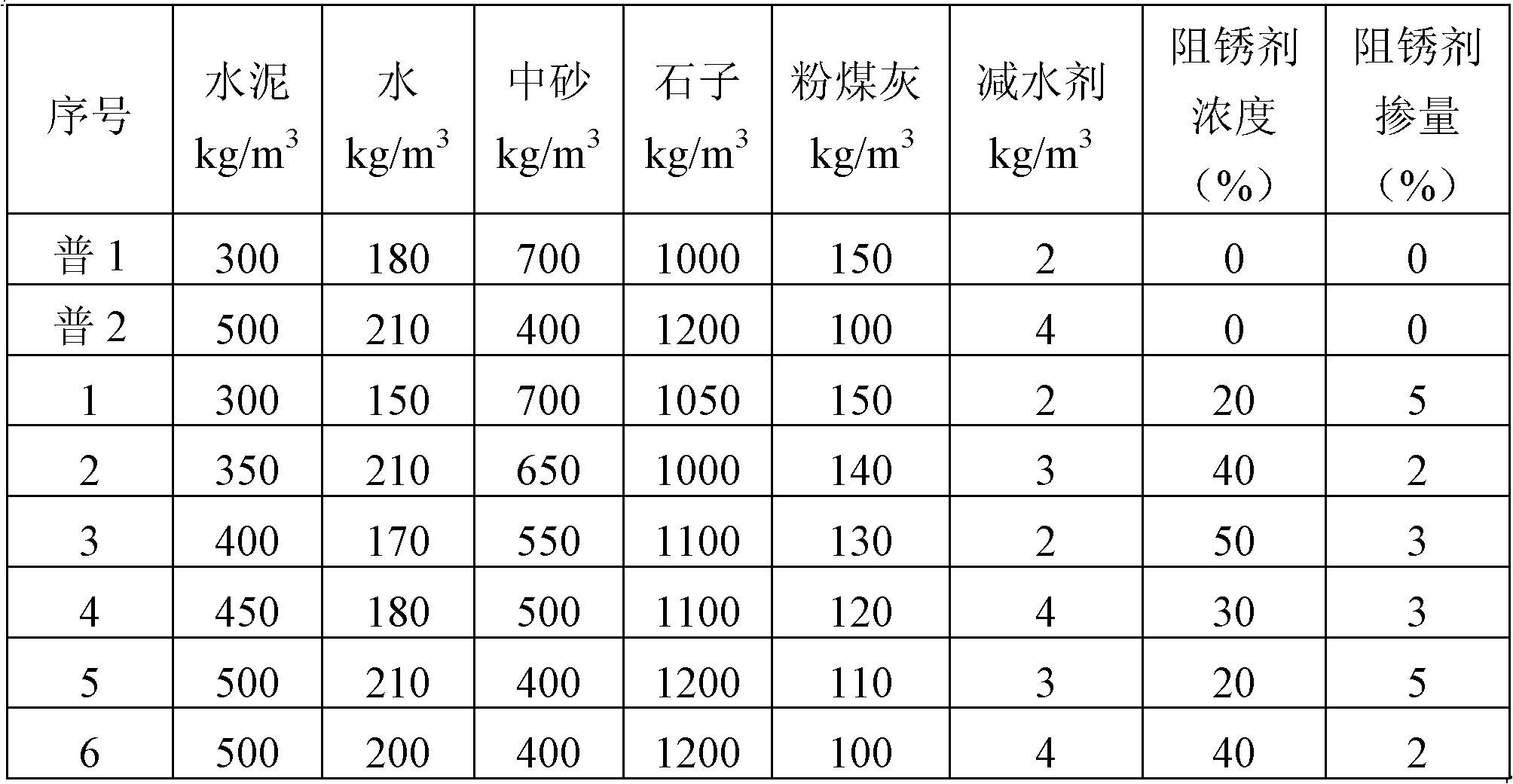

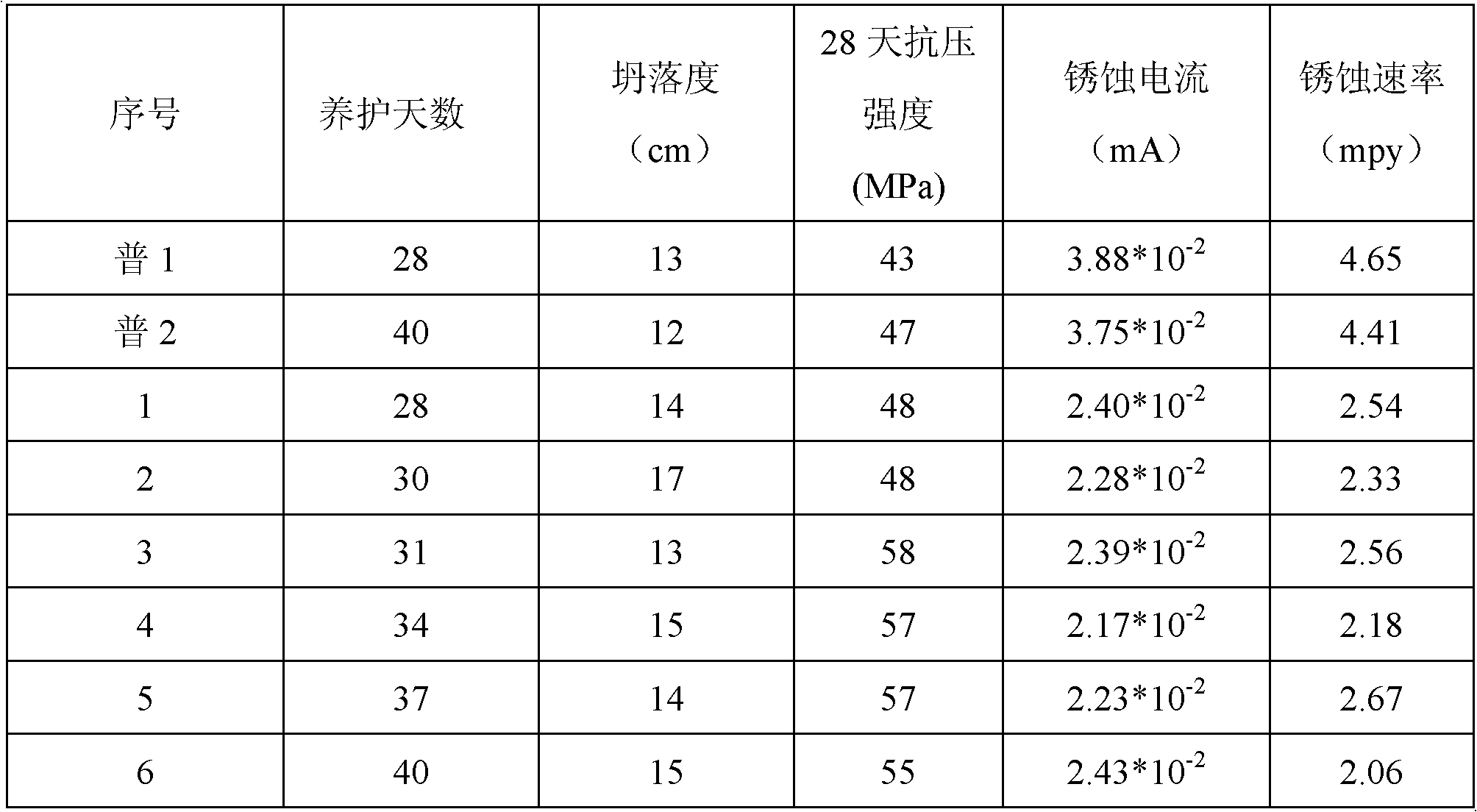

[0021] The cement described in the present invention is 42.5 or 52.5 Portland cement; the described fly ash powder is F class I grade fly ash, fineness ≤ 12%, water demand ratio ≤ 95%, burning vector ≤ 5% , water content ≤ 1%, sulfur trioxide ≤ 3%, free calcium oxide ≤ 1%; the coarse aggregate is 5-25mm continuously graded crushed stone or river pebble; the fine aggregate is fineness Medium sand with a modulus of 2.3-2.7; the described water reducer is a polycarboxylate solid high-efficiency water reducer; the described rust inhibitor is aminocarboxylic acid, dimethylethanolamine and calcium molybdate in a ratio of 1:2: The mass ratio of 2 is uniformly mixed and dissolved in water, and the mass concentration range of the mixture is 20%-50%.

[0022] The present invention will be specifically described below in conjunction with the examples, but the present invention is not limited to the following examples. The present invention provides 6 embodiments, respectively numbered 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com