Method and device for surface passivation of tantalum metal

A metal surface and metal technology, which is applied in the field of passivation of tantalum powder or porous tantalum metal surface for the production of electrolytic capacitors, can solve the problems of low productivity, unsuitable, long passivation time, etc., achieve low oxygen content, save time, Good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

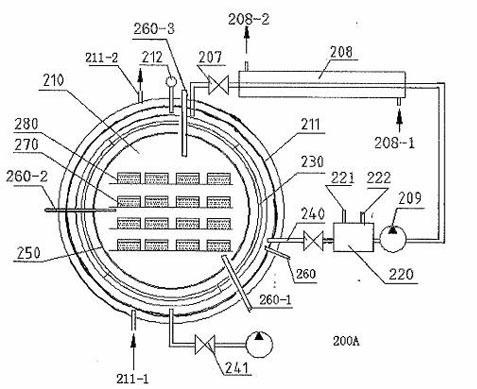

[0068] With a specific surface area of 1.79m 2 / g, bulk density is 0.50g / cm 3 , the porosity is 97.0% and the oxygen content is 6200ppm The original powder prepared by reducing potassium fluorotantalate with sodium is mixed with 120ppm of phosphorus according to the weight of tantalum powder, and then spheroidized and granulated to obtain a bulk density of 1.01 g / cm 3 Particles with a porosity of 93.9%. Pour the above spheroidized and granulated tantalum powder into a tantalum crucible, the porosity of which is 96.8% of that of the original powder, and put the crucible into figure 2 In the tantalum powder heat treatment passivation device shown, the thickness of the tantalum powder in the tantalum crucible is about 45 mm. In the multiple tantalum crucibles on the same horizontal plane, there is a gap of about 1 cm between the tantalum crucibles. There is a 3cm gap, so put it into the vacuum heat treatment furnace, under the pressure of 1.33×10 -1Heat to 1200°C in a vacuu...

Embodiment 2

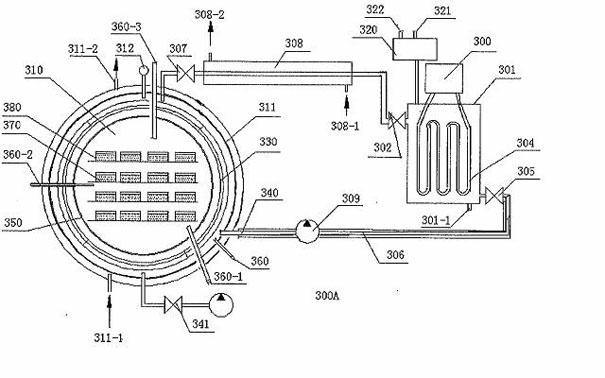

[0071] Carry out granulation equally with the same tantalum powder of embodiment 1, pour granulation tantalum powder in the tantalum crucible, crucible is packed into such as image 3 In the tantalum powder heat treatment passivation device shown, the thickness of the tantalum powder in the tantalum crucible is about 45 mm. In the multiple tantalum crucibles on the same horizontal plane, there is a gap of about 1 cm between the tantalum crucibles, so that the vacuum In the heat treatment furnace, at a pressure of 1.33×10 -1 Heating to 1200°C in a vacuum below Pa for 30 minutes, then stop heating, and after cooling down to 120°C, close 322, feed argon gas from 321 into the reaction chamber, close 321 and start cycle 309 after the pressure reaches about 0.1MPa, Argon gas enters the lower part of the reaction chamber from the gas inlet 340, and the argon gas extracted from the upper gas outlet 307 is cooled by the cooling pipe 308 through which cooling water with a temperature of...

Embodiment 3

[0077] For the passivation of tantalum powder after deoxidation heat treatment, the S-2h tantalum powder after the heat treatment in Example 2 is calculated as tantalum powder and mixed with 2 wt% magnesium powder to form a mixed powder, and the above mixed powder is loaded into such as Figure 5 In the shown tantalum powder deoxidation reaction chamber, there is a gap of about 6 cm between the crucibles of each layer, and a gap of about 8 cm between the crucible and the side wall of the reaction chamber; the above-mentioned tantalum powder is deoxidized at 850 ° C for 3 hours, and the heating is stopped. , cooling down, doping nitrogen at 250°C, and then lowering the temperature to 32°C in argon according to the same method as in Example 1, then performing passivation treatment in the same way as in Example 1, and performing the passivation treatment for the first to eighth times as follows Table 4 is evacuated and filled with air, and the temperature of the gas entering the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com