Spinel film with controllable feature and preparation method thereof

A spinel and thin film technology, applied in the field of spinel thin film and its preparation, can solve the problems of cumbersome post-processing, thin film peeling, expensive raw materials, etc., and achieve the effects of improving efficiency, porous structure, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Pretreatment of the surface of the aluminum sheet: ultrasonically clean the aluminum sheet with ethanol and acetone for 10 minutes to remove impurities and oil on the surface, and then soak it in 1% hydrochloric acid or sodium hydroxide solution to remove the surface oxide layer;

[0027] Weigh 0.5956g of Zn(NO 3 ) 2 And the urea of 4.8048g, be dissolved in the mixed solution of the ethanol / water that 80ml equal volume mixes and prepare reaction solution, wherein urea and Zn 2+ The molar ratio is 40:1, where Zn 2+ The molar concentration of urea is 0.025mol / L, and the concentration of urea is 1mol / L.

[0028] Suspend the pretreated aluminum substrate in the reaction solution, place it at 180°C for 24 hours, take out the substrate, wash it with ethanol, and dry it naturally to obtain a spinel film grown in situ on the surface of aluminum and aluminum alloy. The molecular formula of the spinel film is ZnAl 2 o 4 .

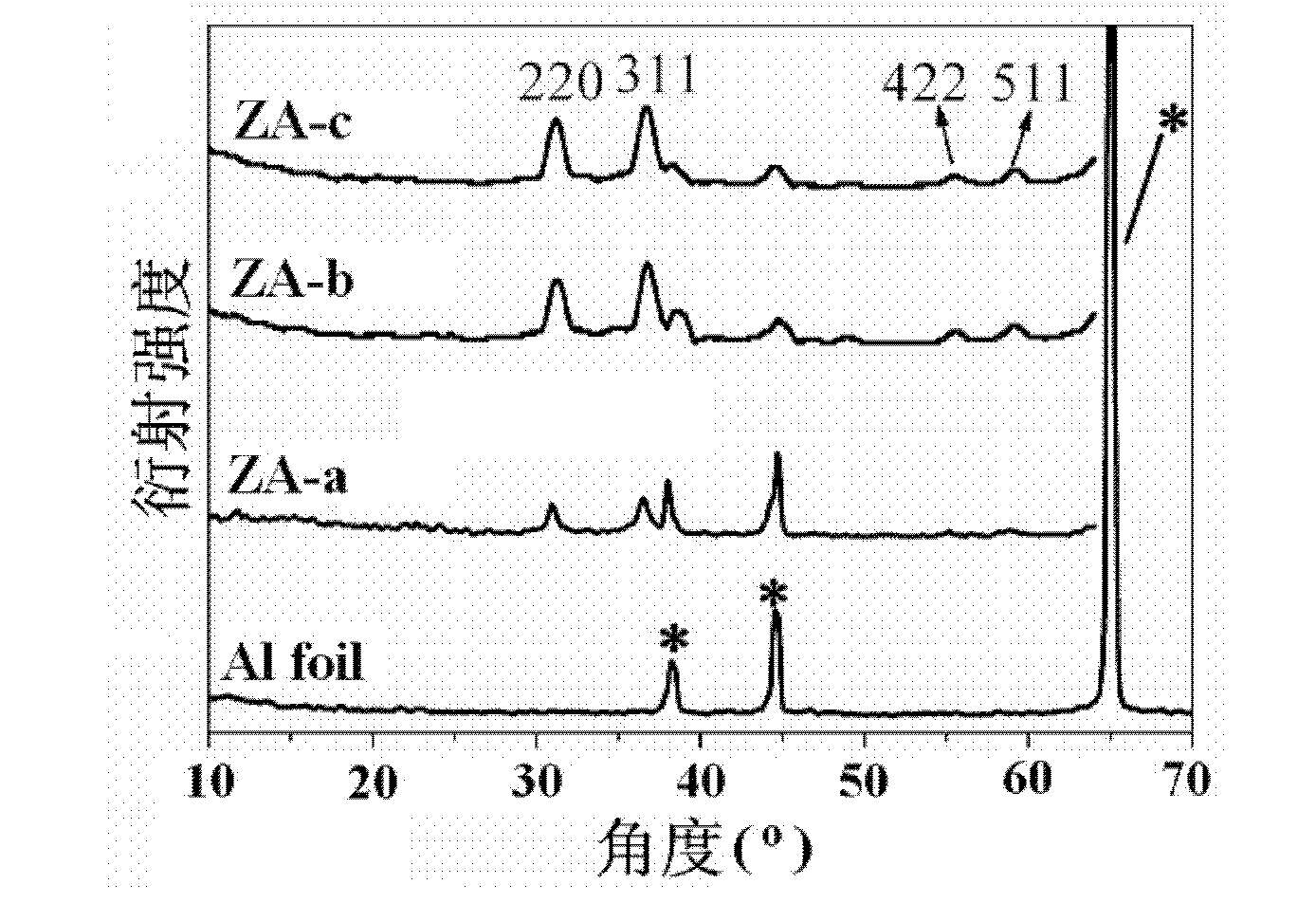

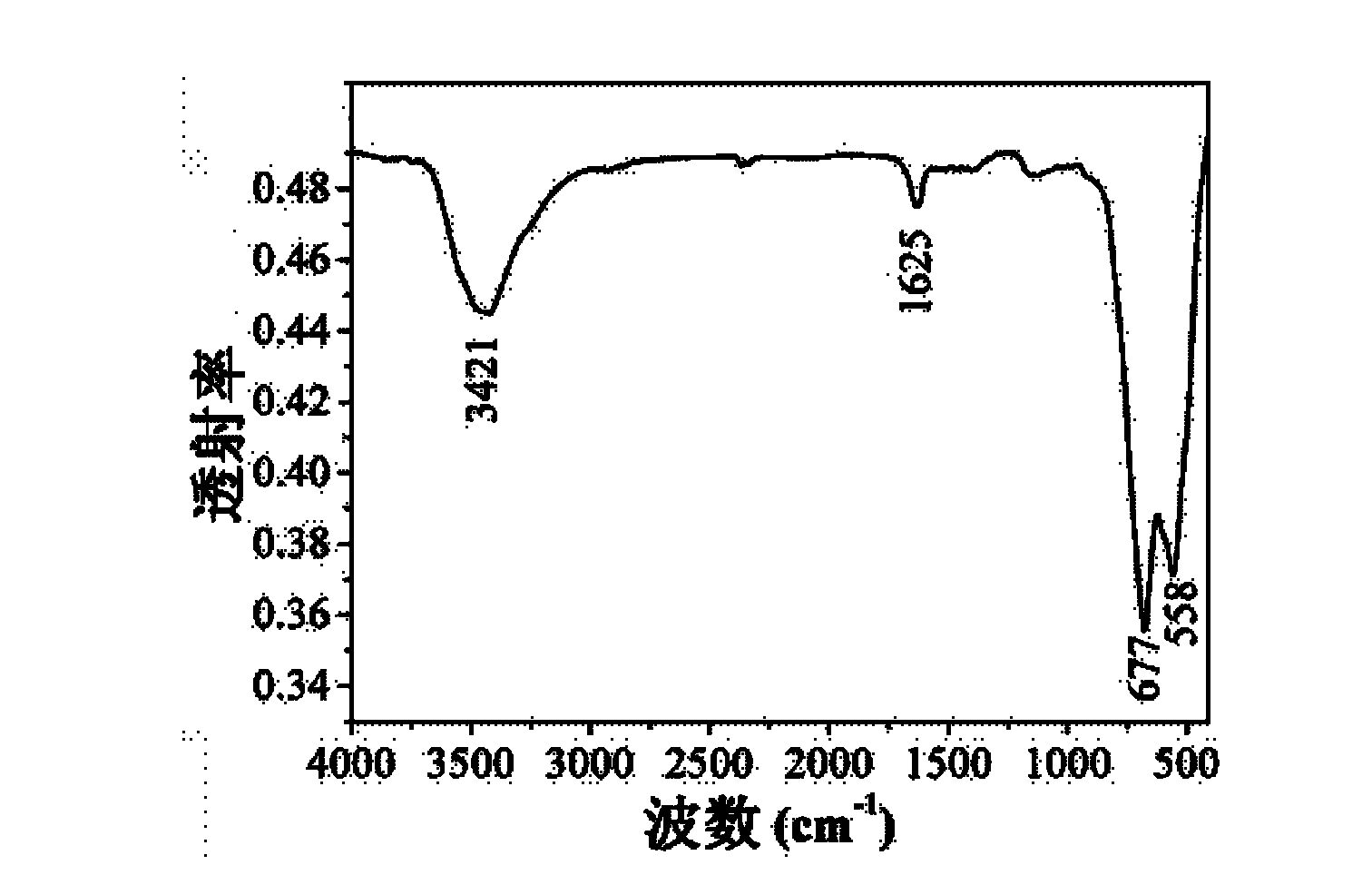

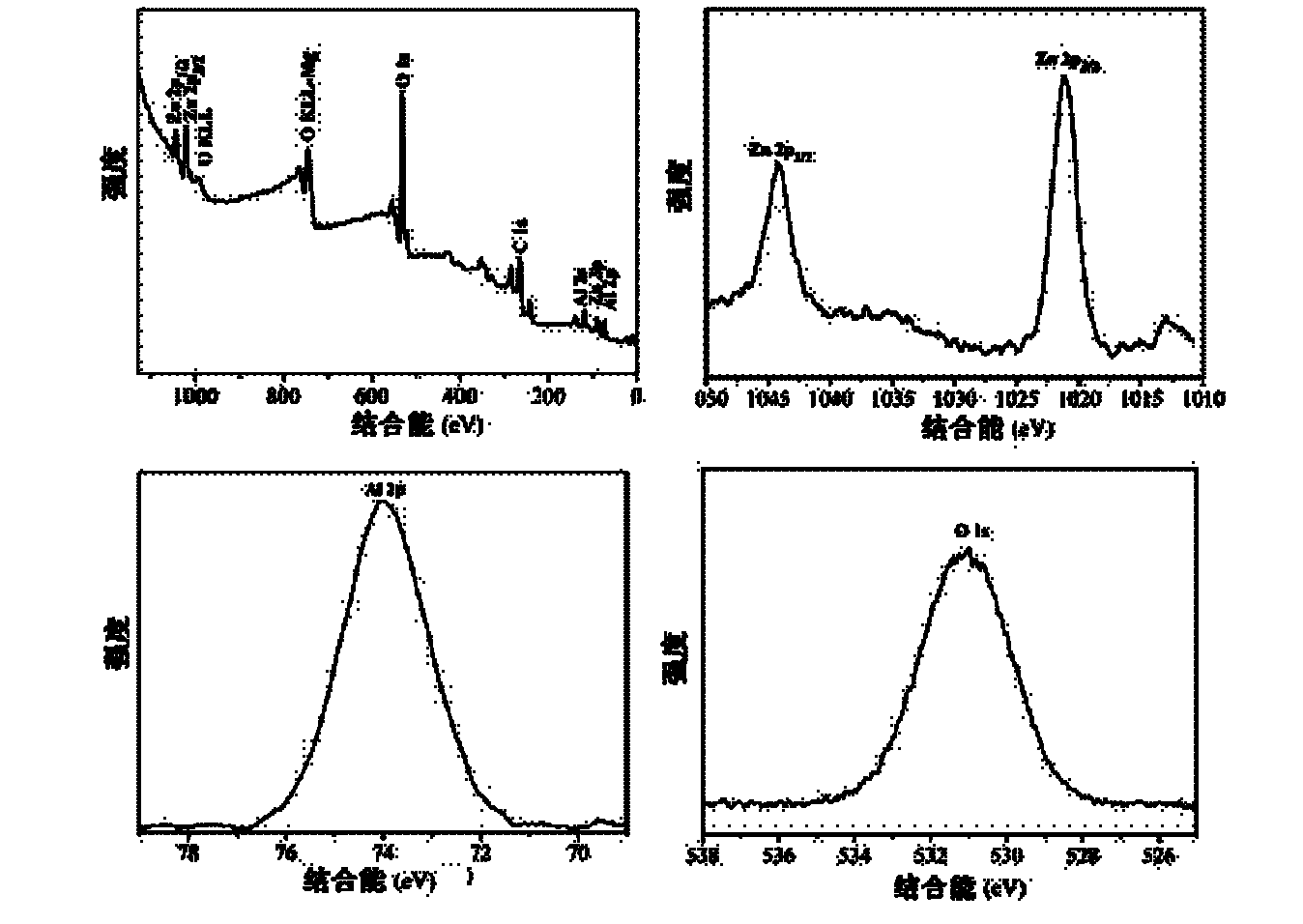

[0029] The surface of the obtained film has a gr...

Embodiment 2

[0031] Pretreatment of the surface of the aluminum substrate: Ultrasonic cleaning of the aluminum parts with ethanol and acetone for 10 minutes to remove impurities and oil on the surface, and then soaking in 1% hydrochloric acid or sodium hydroxide solution to remove the surface oxide layer;

[0032] Weigh 1.1912g of Zn(NO 3 ) 2 And the urea of 4.8048g, be dissolved in the mixed ethanol / water mixed solution of 80ml equivolume and prepare reaction solution, wherein urea and Zn 2+ The molar ratio is 20:1, where Zn 2+ The molar concentration of urea is 0.05mol / L, and the concentration of urea is 1mol / L.

[0033] Suspend the pretreated aluminum substrate in the reaction solution, and place it at 180° C. for 24 hours. Then take out the aluminum substrate, wash it with ethanol, and dry it naturally to obtain a spinel film grown in situ on the surface of aluminum and aluminum alloy. The molecular formula of the spinel film is ZnAl 2 o 4 .

[0034] The surface of the obtained...

Embodiment 3

[0036] Pretreatment of the surface of the aluminum substrate: Ultrasonic cleaning of the aluminum parts with ethanol and acetone for 10 minutes to remove impurities and oil on the surface, and then soaking in 1% hydrochloric acid or sodium hydroxide solution to remove the surface oxide layer;

[0037] Weigh 1.1912g of Zn(NO 3 ) 2 And the urea of 9.6096g, be dissolved in the mixed ethanol / water mixed solution of 80ml equivolume and prepare reaction solution, wherein urea and Zn 2+ The molar ratio is 40:1, where Zn 2+ The molar concentration of urea is 0.05mol / L, and the concentration of urea is 2mol / L.

[0038] Suspend the pretreated aluminum substrate in the reaction solution, and place it at 180° C. for 24 hours. After taking out the aluminum substrate, cleaning it with ethanol, and drying it naturally to obtain a spinel film grown in situ on the surface of aluminum and aluminum alloy, the molecular formula of the spinel film is ZnAl 2 o 4 .

[0039] The surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com