Thin film solar cell with improved photoelectric conversion efficiency and manufacturing method thereof

The technology of a solar cell and a manufacturing method, applied in the field of solar cells, can solve the problems of low photoelectric conversion efficiency and high production cost of solar cells, and achieve the effects of improved photoelectric conversion efficiency, low cost, and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below by specific processing steps:

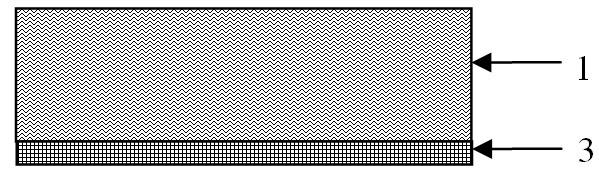

[0022] 1. Use a polysilicon film sample with a thickness of about 1um, which has been doped to form a p-n junction and deposited metal aluminum as the back electrode. After the standard RCA cleaning process, use a 2% HF dilution solution to remove the intrinsic oxide layer on the surface of the silicon wafer, such as figure 1 shown.

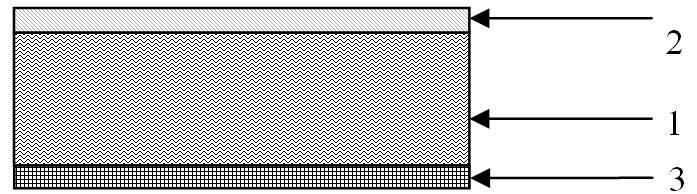

[0023] 2. Apply physical vapor deposition technology to deposit 20nm thick indium tin oxide (ITO: Indium Tin Oxides) on a large area of silicon film as a surface transparent electrode, such as figure 2 shown.

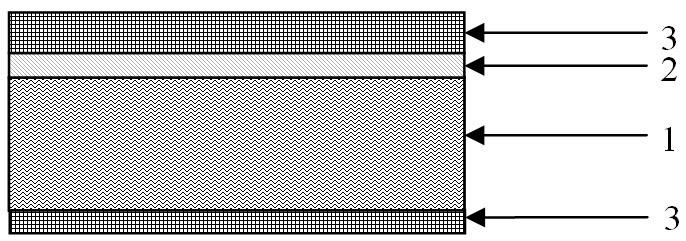

[0024] 3. Apply physical vapor deposition technology to deposit 100nm thick aluminum film on the surface of ITO, such as image 3 shown.

[0025] 4. Spin-coat photoresist on the aluminum film, use positive resist for photoresist, such as Figure 4 shown.

[0026] 5. Use positive photoresist exposure and development to form a cylindrical array p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com