Manufacturing method of modulation-doped gallium nitride series light-emitting diode

A light-emitting diode, modulation doping technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of reduced luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

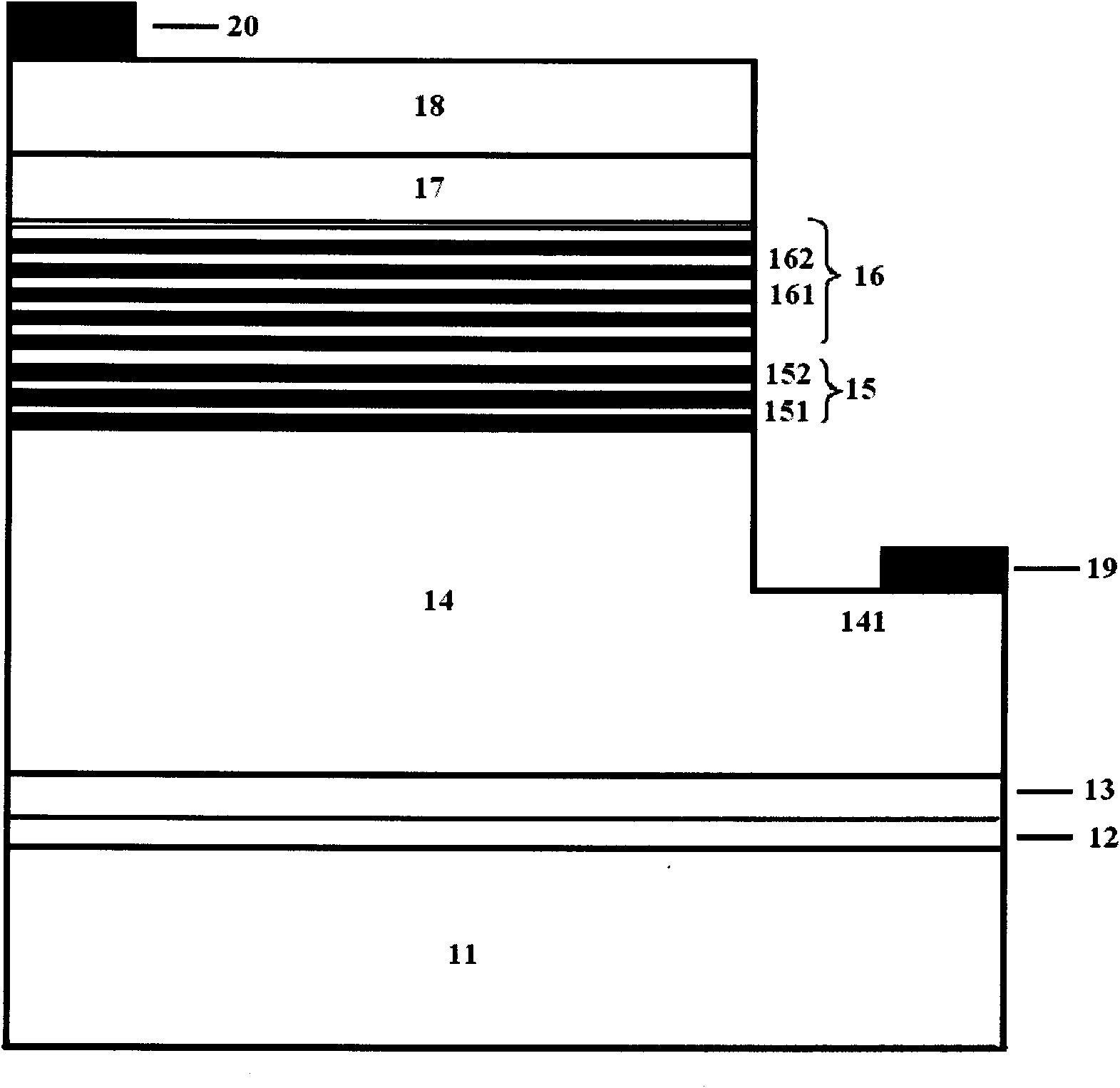

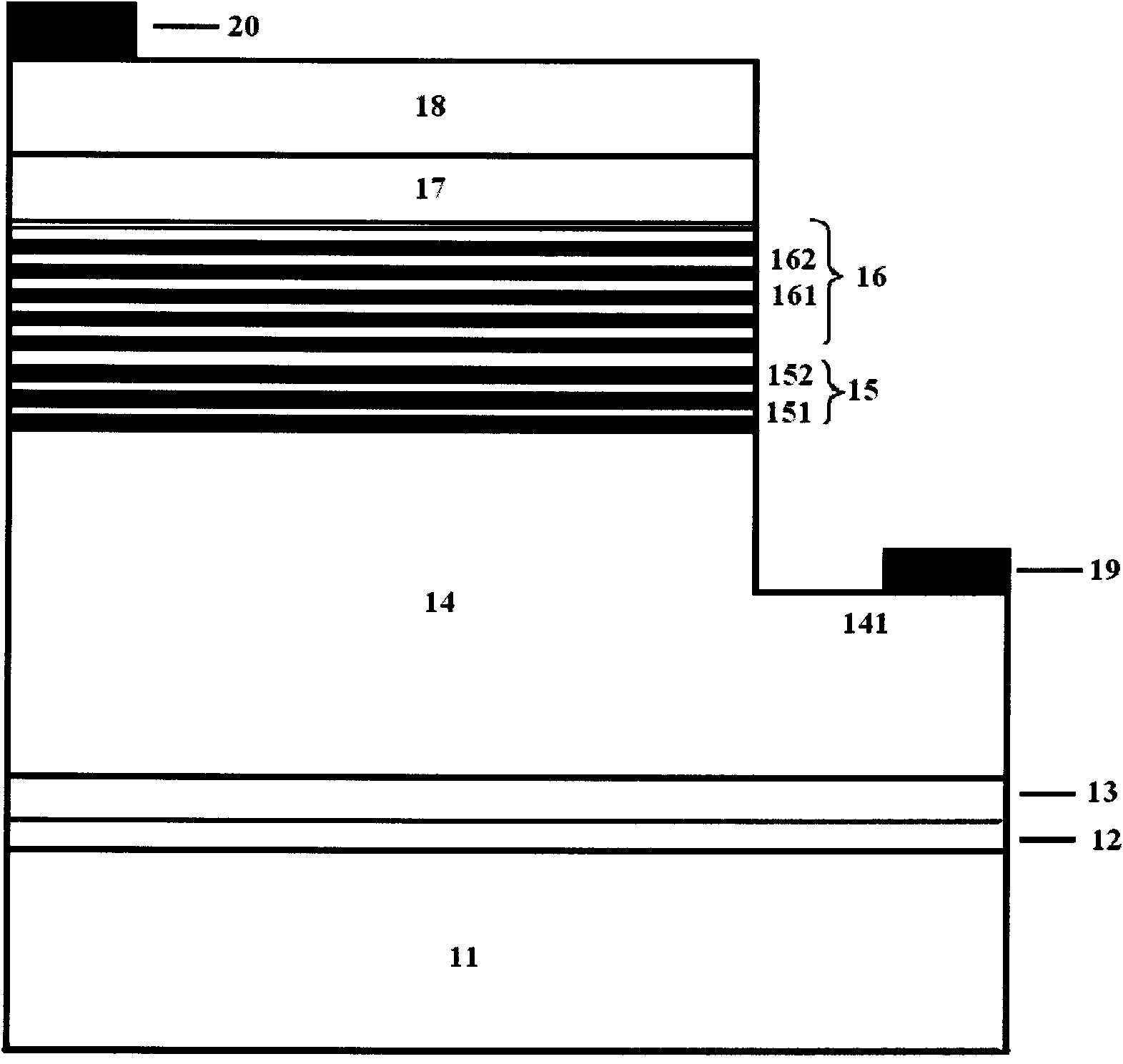

[0024] see figure 1 As shown, the present invention provides a method for manufacturing a modulated doped gallium nitride-based light-emitting diode, the manufacturing process of which is as follows:

[0025] Step 1: Take a substrate 11, and use (0001) to sapphire (Al 2 o 3 ) is the substrate 11, and other materials that can be used for the substrate 11 also include aluminum oxide single crystals on the R-plane or A-plane, 6H-SiC, 4H-SiC, or single crystal oxides whose lattice constants are close to those of nitride semiconductors thing. High-purity NH was used in the preparation 3 As N source, high-purity H 2 and N 2 mixed gas as carrier gas; trimethylgallium or triethylgallium as Ga source, trimethylindium as In source, trimethylaluminum as Al source; n-type dopant is silane, p-type dopant is Magnesium dichloride.

[0026] Step 2: sequentially fabricate a GaN nucleation layer 12 and a GaN buffer layer 13 on the substrate 11 . The growth parameters of the nucleation l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com