Preparation method of hoof nail polypeptide through composite hydrolysis

A technology for compound hydrolysis and hoof nails is applied in the field of hydrolysis to prepare hoof nail polypeptides, which can solve the problems of no drug effect, unfavorable actual curative effect, improvement and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

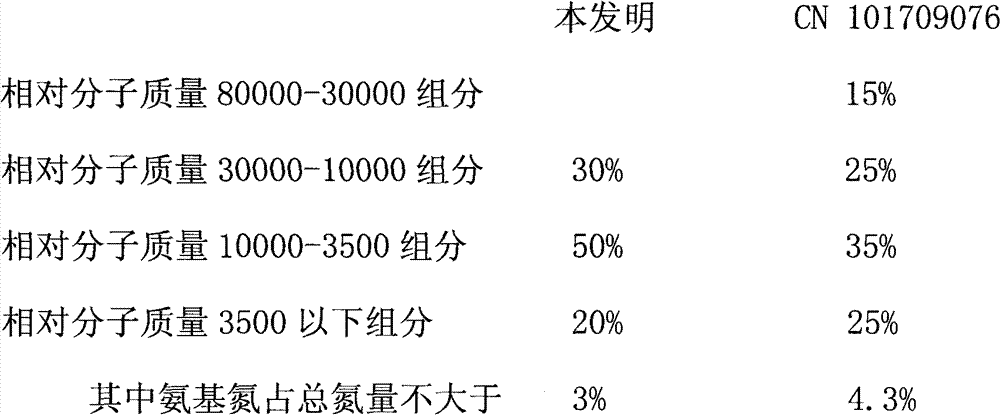

Image

Examples

Embodiment 1

[0021] 1) Washing, pyrolyzing, drying and pulverizing the raw hoof shells to obtain raw material powder;

[0022] 2) Put the raw material powder in a NaOH solution whose weight is 20 times that of the raw material dry powder and whose pH is 8.6, stir evenly at a temperature of 86°C, and perform alkaline hydrolysis for 11 hours;

[0023] 3) After the hydrolysis mixture is filtered to remove the coarse residue, then the filtrate is ultrafiltered with an ultrafiltration membrane with a molecular weight not greater than 30,000 Daltons, and the obtained filtrate is subjected to enzymatic hydrolysis; the filtered residue filtered out twice is returned to the NaOH solution for further processing alkaline hydrolysis;

[0024] 4) in the filtrate of ultrafiltration gained, add the papain (enzyme activity 1000 μ / mg) that weight is raw material dry powder 0.15% and the serrapeptase (enzyme activity 300,000 μ / g) that weight is raw material dry powder 0.2%, adjust The pH of the solution is...

Embodiment 2

[0030] 1) Washing, pyrolyzing, drying and pulverizing the raw hoof shells to obtain raw material powder;

[0031] 2) Put the raw material powder in a NaOH solution whose weight is 22 times that of the raw material dry powder and whose pH is 8.4, and stir evenly at a temperature of 84°C, and perform alkaline hydrolysis for 12 hours;

[0032] 3) After the hydrolysis mixture is filtered to remove the coarse residue, then the filtrate is ultrafiltered with an ultrafiltration membrane with a molecular weight not greater than 30,000 Daltons, and the obtained filtrate is subjected to enzymatic hydrolysis; the filtered residue filtered out twice is returned to the NaOH solution for further processing alkaline hydrolysis;

[0033] 4) in the filtrate of ultrafiltration gained, add the papain (enzyme activity 1000 μ / mg) that weight is raw material dry powder 0.2% and the serrapeptase (enzyme activity 300,000 μ / g) that weight is raw material dry powder 0.15%, adjust The pH of the solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com