Method for evaporating indium tin oxide (ITO)

A technology of evaporation and evaporation rate, applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve problems such as insufficient brightness, and achieve improved chip brightness, uniform current expansion, and high light transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The method for evaporating ITO of the present invention will be described in detail below through specific examples.

[0019] See Figure 4 , the method for evaporation ITO of the present invention mainly comprises the following steps:

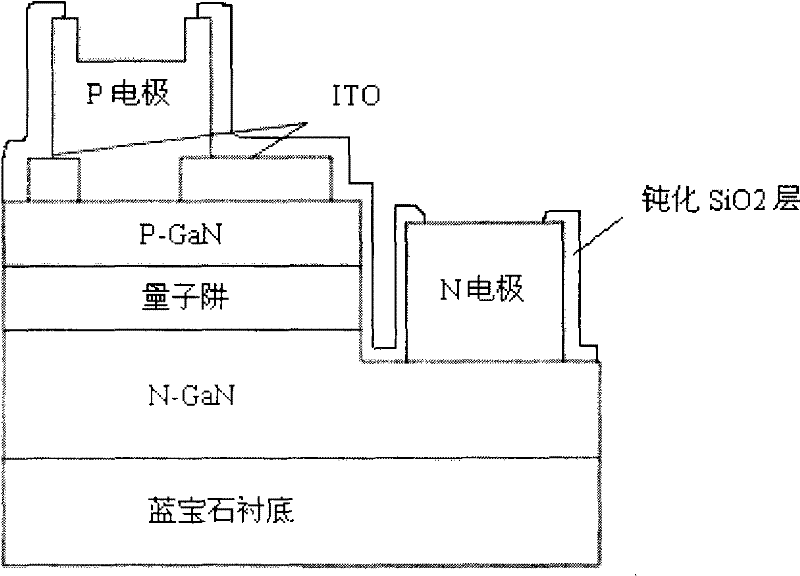

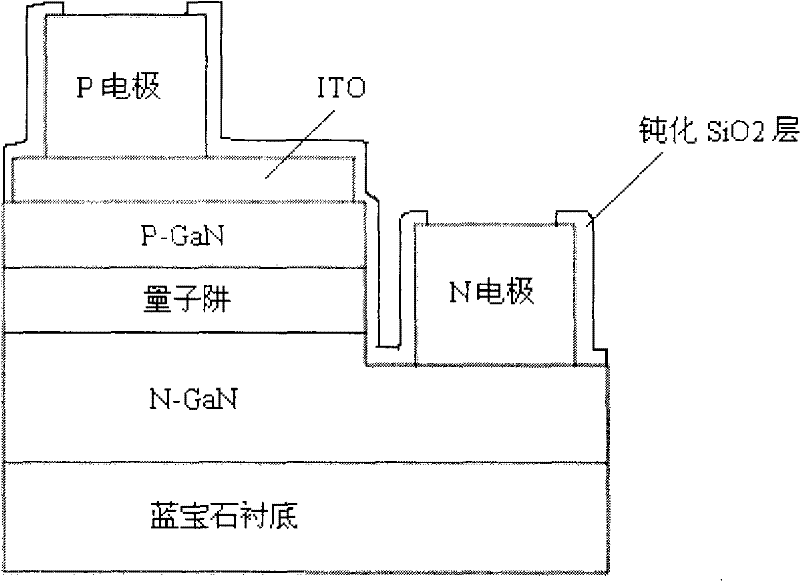

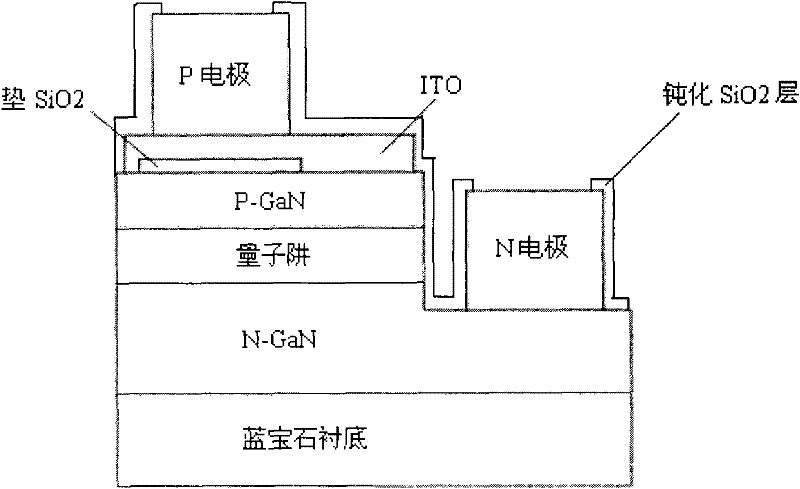

[0020] First, the semiconductor structure to be deposited with ITO (indium tin oxide thin film) is placed on the substrate plate, and the vacuum is evacuated until the vacuum degree of the cavity of the electron beam evaporation machine reaches 5×10 -6 Torr above. In this embodiment, the semiconductor structure is a semiconductor structure for preparing LED chips, which includes a sapphire substrate and a GaN semiconductor layer, wherein the GaN semiconductor layer includes an N-GaN layer, a quantum well, and a P-GaN layer .

[0021] Next, start to rotate the substrate plate, heat it to 240-350° C. and stabilize it for 10-30 minutes.

[0022] Then, open the oxygen valve, and start pre-plating the semiconductor structure when the oxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com