Electrostatic image developing toner and two-component developer

一种静电图像显影、调色剂的技术,应用在显影剂、电记录术、仪器等方向,能够解决蜡分散性不足、保持、耐反印性分离性、高温存储性和抗成膜性改进不足等问题,达到优异存储性、改进分散性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

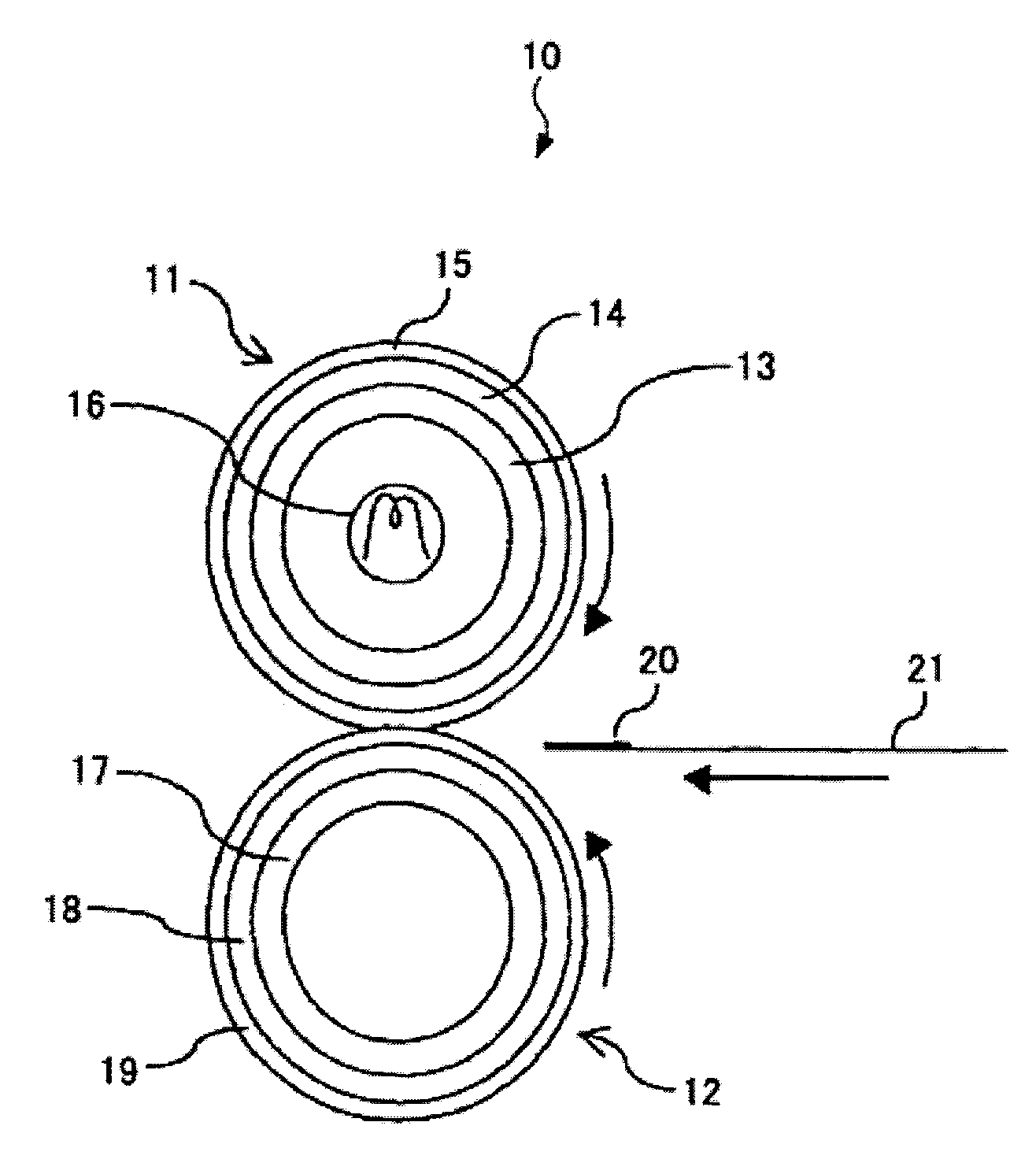

Image

Examples

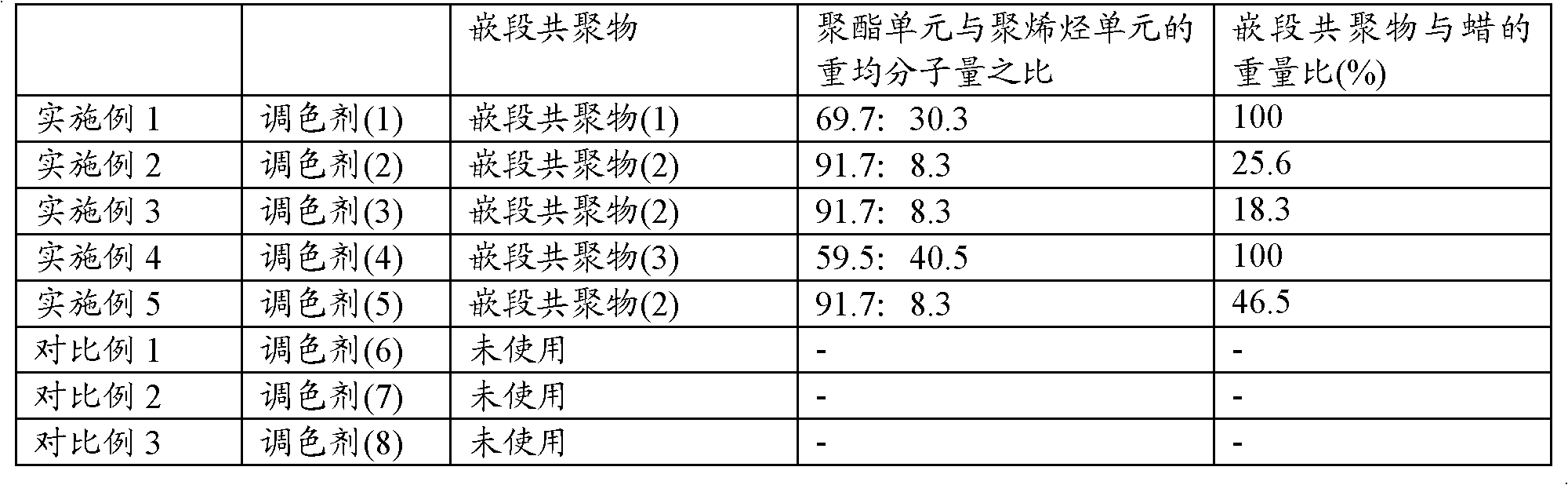

Embodiment 1

[0145]

[0146] Into the reaction kettle equipped with cooling tube, stirrer and nitrogen gas introduction tube, pour 690 parts of bisphenol A ethylene oxide (2mol) adduct and 335 parts of terephthalic acid, make it in the normal pressure nitrogen flow The condensation reaction was carried out at 210°C for 10 hours. Thereafter, while removing water under a reduced pressure of 10 mmHg to 15 mmHg, the reaction was continued for 5 hours, followed by cooling, whereby polyester (1) was obtained. The obtained polyester (1) had a weight average molecular weight of 6,000 and an acid value of 10 KOHmg / g and a glass transition temperature of 48°C.

[0147]

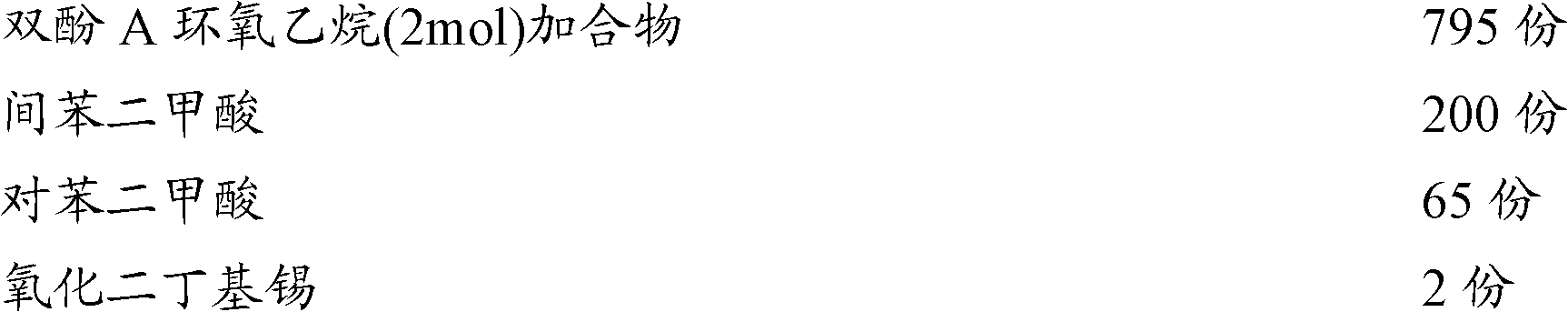

[0148] The following components were poured into a reaction kettle equipped with a cooling pipe, a stirrer and a nitrogen gas introduction pipe, and allowed to undergo a condensation reaction at 210° C. for 8 hours in an atmospheric nitrogen flow.

[0149]

[0150]Next, while removing water under a reduced pressure of 10 mmH...

Embodiment 2

[0163]

[0164] Into a reaction kettle equipped with a cooling pipe, a stirrer, and a nitrogen gas introduction pipe, 622 parts of hydroxyl-terminated polybutadiene (product name: POLY BD R-15HT, manufactured by Idemitsu Kosan Co., Ltd., number average molecular weight : 1,200, hydroxyl value: 102.7 mg KOH / g) and 378 parts of terephthalic acid were subjected to condensation reaction at 200° C. for 9 hours in a nitrogen stream at normal pressure. Then, while removing water under a reduced pressure of 10 mmHg to 15 mmHg, the reaction was continued for 5 hours, and then cooled, thereby obtaining a resin (2) having a polyolefin skeleton (hereinafter referred to as "polyolefin skeleton-containing resin (2)") . The obtained polyolefin skeleton-containing resin (2) had a weight average molecular weight of 1,830.

[0165] Subsequently, pour 660 parts of bisphenol A ethylene oxide (2mol) adducts and 340 parts of terephthalic acid into a reaction kettle equipped with a cooling pipe, ...

Embodiment 3

[0170]

[0171] The production process was implemented in the same manner as in Example 1, except that 14.3 parts of prepolymer (1), 54 parts of polyester (1) and 1.1 parts of block copolymer (2) were mixed into 78.6 parts of ethyl acetate, and then Stir and dissolve, then add 6.0 parts of paraffin wax as a release agent, 4 parts of copper phthalocyanine blue pigment, and 2 parts of organically modified montmorillonite. Thus, toner (3) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com