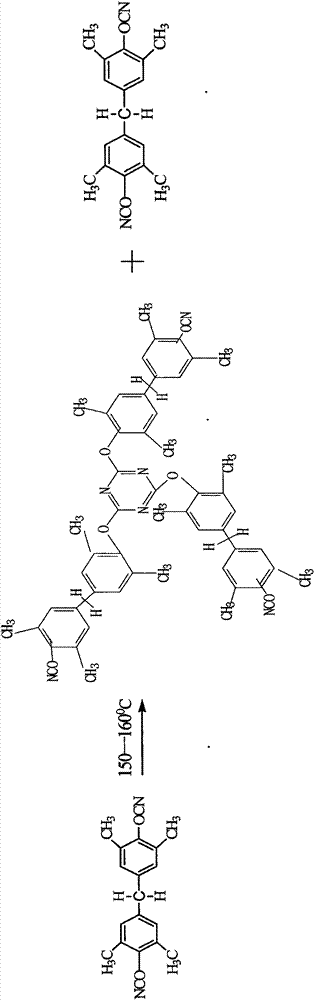

Method for preparing tetramethyl bisphenol F type cyanate resin prepolymer

A technology of cyanate ester resin and tetramethylbisphenol, which is applied in the field of preparation of cyanate ester resin prepolymer to achieve the effect of maintaining excellent electrical properties and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

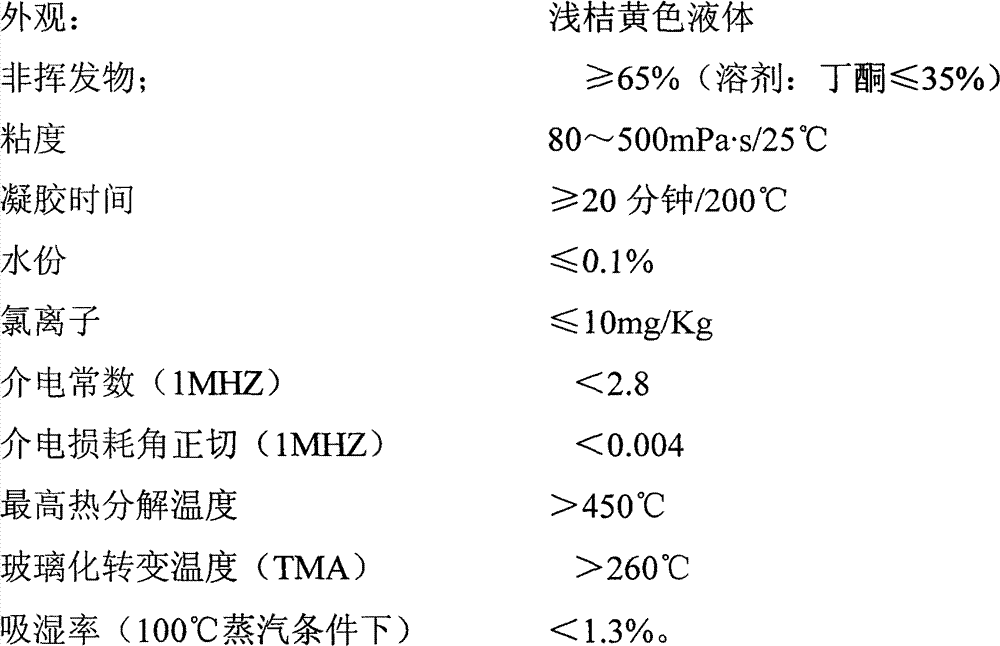

example 1

[0015] In a 1000ml four-neck flask, add 500g of solid tetramethylbisphenol F-type cyanate resin, feed nitrogen, slowly heat up the material to 120°C with an oil bath to melt, and add an appropriate amount of 0.05g of nonylphenol ; Then, continue to heat up to .170°C, and keep warm for 10 hours at 170±1°C under the protection of nitrogen. Then test its refractive index with a refractometer, and when it is 1.5750 / 84°C (1.5600 / 110°C), cool the reactant to about 75°C with cold oil. Then add 250 grams of butanone to form a liquid with a concentration of 65%, and cool to 20° C. to obtain a tetramethyl bisphenol F type cyanate resin prepolymer solution. Non-volatile matter ≥ 65.36%, viscosity: 500mPa·s / 25°C, yield: 99.85%.

example 2

[0017] In a 1000 ml four-neck flask, add 600 g of solid tetramethylbisphenol F-type cyanate resin, pass through nitrogen, and slowly heat up the material to 110 ° C with an oil bath to melt. When the material is completely melted, add benzene Ethylene 0.06 g; continue to heat up to 160 ° C, under the protection of nitrogen at 160 ± 1 ° C, heat preservation for 12 hours. Test its refractive index with a refractometer, and when it is 1.5700 / 84°C (1.5550 / 110°C), cool the reactant to about 75°C with cold oil. Slowly add 320 grams of butanone to form a liquid with a concentration of 65%, and cool to 30° C. to obtain a tetramethyl bisphenol F type cyanate resin prepolymer solution. Non-volatile matter ≥ 65.22%, viscosity: 250mPa·s / 25°C, yield: 99.9%.

example 3

[0019] In a 1000 ml four-necked flask, add 700 grams of solid tetramethylbisphenol F-type cyanate resin, feed nitrogen, use an oil bath to slowly heat up the material to 125 ° C for melting, add 0.07 grams of dimethylimidazole, Then continue to heat up to 150°C, and keep warm at 150±1°C for 15 hours under the protection of nitrogen. Then test its refractive index with a refractometer, and when it is 1.5650 / 84°C (1.5450 / 110°C), cool the reactant to about 75°C with cold oil. Slowly add 370 grams of butanone to form a liquid with a concentration of 65%, and cool to room temperature to obtain a tetramethyl bisphenol F type cyanate resin prepolymer solution. Non-volatile matter ≥ 65.42%, viscosity: 80mPa·s / 25°C, yield: 99.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com