Stable red fluorescent material, its preparation method and method for enhancing luminescent efficiency

A technology of red fluorescence and white light, which is applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of application limitations, unstable chemical properties of sulfide, etc., and achieve simple synthesis methods, enhanced stability and fluorescence intensity, easy-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] According to a preferred embodiment of the present invention, the present invention provides a borate red fluorescent material for white light LEDs, the chemical composition of the borate red fluorescent material is:

[0039] Na 3 Ca 1-x B 5 o 10 :xEu 3+

[0040] Among them, Na 3 Ca 1-x B 5 o 10 as matrix, Eu 3+ is the doped rare earth ion, x is the molar amount of the doped rare earth ion, 0.005≤x≤0.3. Further, it is preferred that the molar amount x of doped rare earth ions is: 0.008, 0.01, 0.015, 0.02, 0.04, 0.06, 0.08, 0.10, 0.15, 0.20 and 0.25.

[0041] According to another preferred embodiment of the present invention, the borate red fluorescent material further includes charge compensation ions M + , and its chemical composition formula is:

[0042] Na 3 Ca 1-2x B 5 o 10 :xEu 3+ , xM +

[0043] where M + is the monovalent alkali metal ion Li + 、Na + and K + One or more of, x is the doped rare earth ion Eu 3+ or the charge compensating ion ...

Embodiment 1

[0058] Embodiment 1: fluorescent material Na 3 Ca 0.8 B 5 o 10 :0.2Eu 3+ preparation of

[0059] Calcium carbonate (CaCO 3 )0.4504g, anhydrous sodium carbonate (Na 2 CO 3 ) 0.795g, boric acid (H 3 BO 3 ) 1.5475g and europium oxide (Eu 2 o 3 ) 0.176g. After the above raw materials were ground and mixed in an agate mortar, they were put into a corundum crucible and pre-calcined at a temperature of 400°C for 2 hours. Then the pre-calcined powder is cooled, taken out and ground. Then calcined again at a temperature of 750° C. for 10 hours, and after cooling, ground again until pulverized and sieved to obtain the fluorescent material Na 3 Ca 0.8 B 5 o 10 :0.2Eu 3+ .

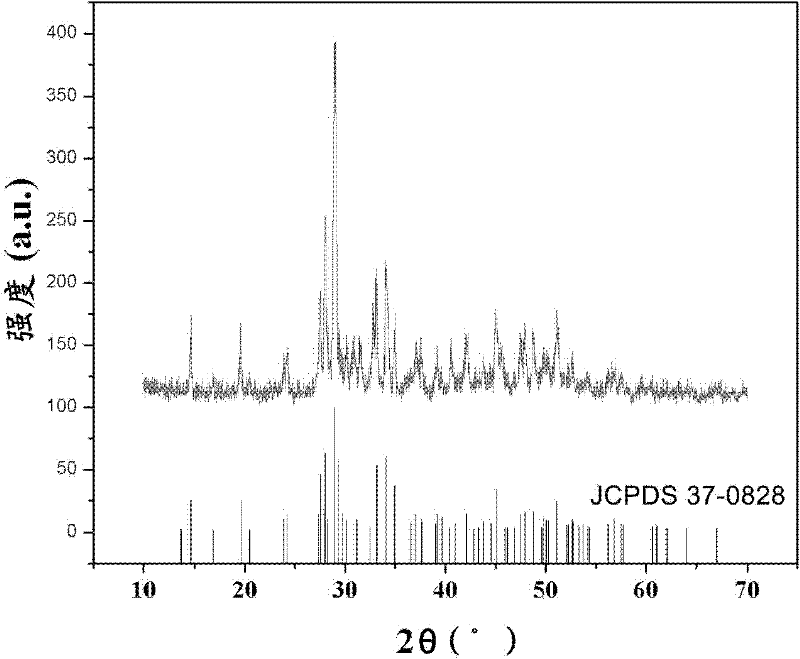

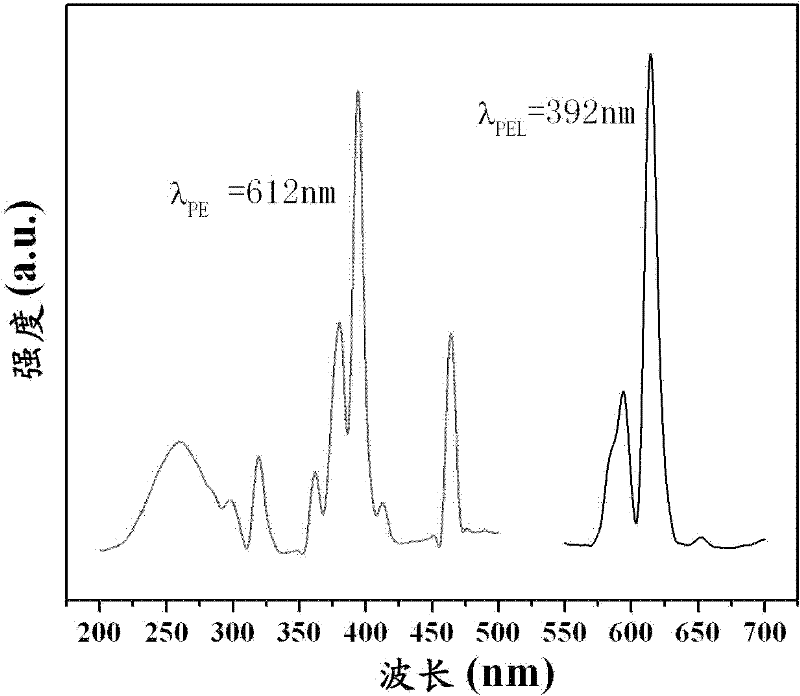

[0060] Adopt Japan Shimadzu XRD-6000 type X-ray polycrystal diffractometer (radiation source is Cu target K α , 40kV, 30mA, λ=0.15406nm, step size 0.02, scan range 10°~70°), measure the X-ray diffraction pattern of the prepared fluorescent material sample, the result is as follows figure 1 shown. ...

Embodiment 2

[0063] Embodiment 2: fluorescent material Na 3 Ca 0.995 B 5 o 10 :0.005Eu 3+ preparation of

[0064] Calcium carbonate (CaCO 3 )0.5005g, anhydrous sodium carbonate (Na 2 CO 3 ) 0.795g, boric acid (H 3 BO 3 ) 1.5475g and europium oxide (Eu 2 o 3 ) 0.0044g. After the above raw materials were ground and mixed in an agate mortar, they were put into a corundum crucible and pre-calcined at a temperature of 400°C for 2 hours. Then the pre-calcined powder is cooled, taken out and ground. Then calcined again at a temperature of 750°C for 10 hours, and after cooling, ground again until pulverized to obtain the fluorescent material Na 3 Ca 0.995 B 5 o 10 :0.005Eu 3+ .

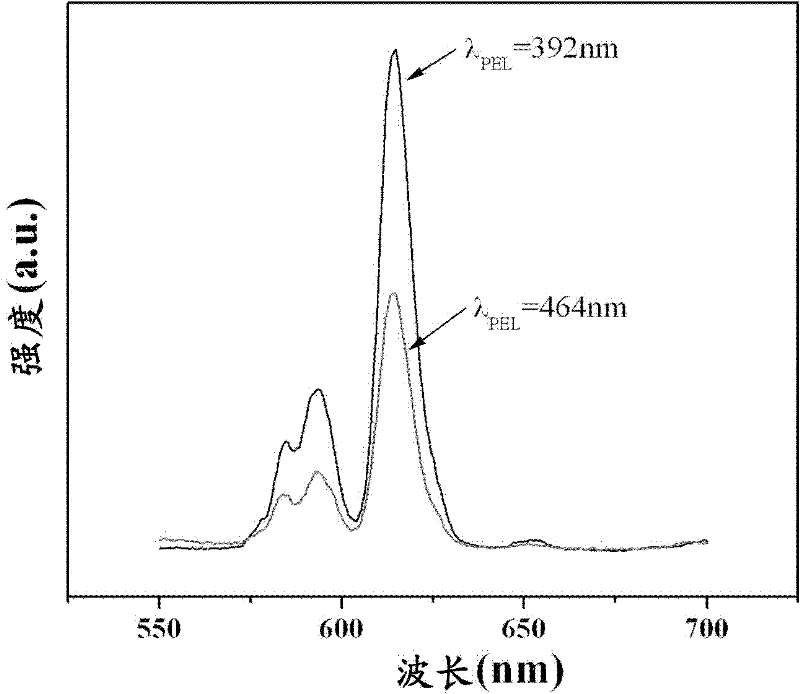

[0065] Same as Example 1, the X-ray diffraction test shows that the prepared fluorescent material is a single crystal phase. The excitation and emission spectra of the prepared red fluorescent materials were tested on a HITACHI F-7000 fluorescence spectrometer. The borate red fluorescent material is ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com