Amino acid adding method for raising sirolimus fermentation yield

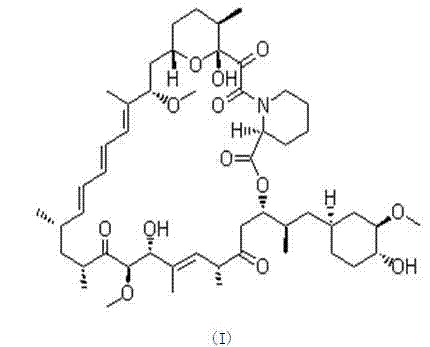

A technology for sirolimus and amino acid is applied in the field of improving the fermentation yield of sirolimus, which can solve the problem of low fermentation level of sirolimus strain, complex metabolic pathway of sirolimus, and regulation of rapamycin biosynthesis. The mechanism is not clear and other problems, to achieve the effect of clear purpose, low fermentation cost, and improved fermentation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1: The components of the fermentation medium are glucose 40g / L, glycerol 50g / L, cottonseed powder 20g / L, lysine salt 10 g / L, NaCl 0.5 g / L, K 2 HPO 4 0.1 g / L.

[0012] The initial pH of the medium was controlled at 6.5, the sterilization temperature was 121°C, and the sterilization time was 30 min; 0.5% proline was added to the initial fermentation medium. The fermentation process adopts the shake flask fermentation process, the liquid volume of 500mL shake bottle is 50 mL, the shaker speed is 220 r / min, and Streptomyces hygroscopicus S. hygroscopicus ATCC 29253 culture seed solution, the inoculum size was 10%, the culture temperature was 30 ℃, the sirolimus fermentation yield increased by 12.39% compared with the control group.

Embodiment 2

[0013] Example 2: The components of the fermentation medium are glucose 40g / L, glycerin 50g / L, cottonseed powder 20g / L, lysine salt 10 g / L, NaCl 0.5 g / L, K 2 HPO 4 0.1 g / L.

[0014] The initial pH of the medium was controlled at 6.5, the sterilization temperature was 121°C, and the sterilization time was 30 min. A mass concentration of 0.5% phenylalanine was added to the initial fermentation medium. The fermentation process adopts the shake flask fermentation process, the liquid volume of 500mL shake bottle is 50 mL, the shaker speed is 220 r / min, and Streptomyces hygroscopicus S. hygroscopicus NRRL5491 was cultured with seed solution, the inoculum size was 10%, and the culture temperature was 30°C. The fermented sirolimus yield increased by 6.8% compared with the control group.

Embodiment 3

[0015] Example 3: The components of the fermentation medium are glucose 40g / L, glycerol 50g / L, cottonseed powder 20g / L, lysine salt 10 g / L, NaCl 0.5 g / L, K 2 HPO 4 0.1 g / L.

[0016] The initial pH of the medium was controlled at 6.5, the sterilization temperature was 121°C, and the sterilization time was 30 min. Glutamic acid and 0.5% glutamine were added to the initial fermentation medium at a mass concentration of 0.5%. The fermentation process adopts the shake flask fermentation process, the liquid volume of 500mL shake bottle is 50 mL, the shaker speed is 220 r / min, and Streptomyces hygroscopicus S. hygroscopicus ATCC 29253 cultured seed liquid, the inoculum amount was 10%, and the culture temperature was 30°C. The fermentation yield of sirolimus glutamic acid was increased by 21.63% compared with the control group; the fermentation yield of sirolimus glutamine was increased compared with the control group 39.74%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com